Heat exchanger with loose lining structure

A technology of heat exchangers and heat exchange tubes, which is applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of wasting time, manpower and cost, medium leakage, high cost, etc., to ensure safety Use, prevent medium leakage, high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions and effects of the present invention will be further described below through specific embodiments. The following embodiments are only used to illustrate the content of the present invention, and are not intended to limit the protection scope of the present invention. Simple changes made to the present invention by applying the concept of the present invention are all within the scope of protection of the present invention.

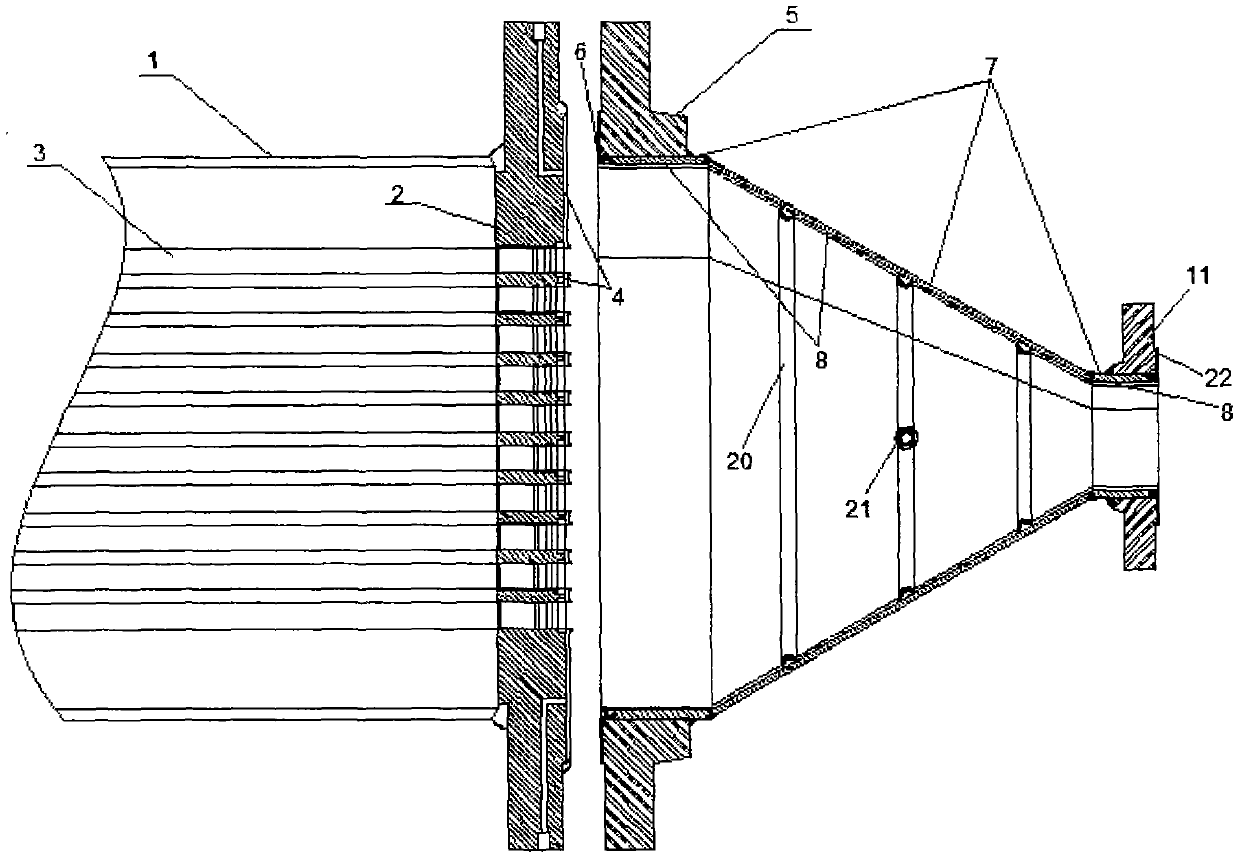

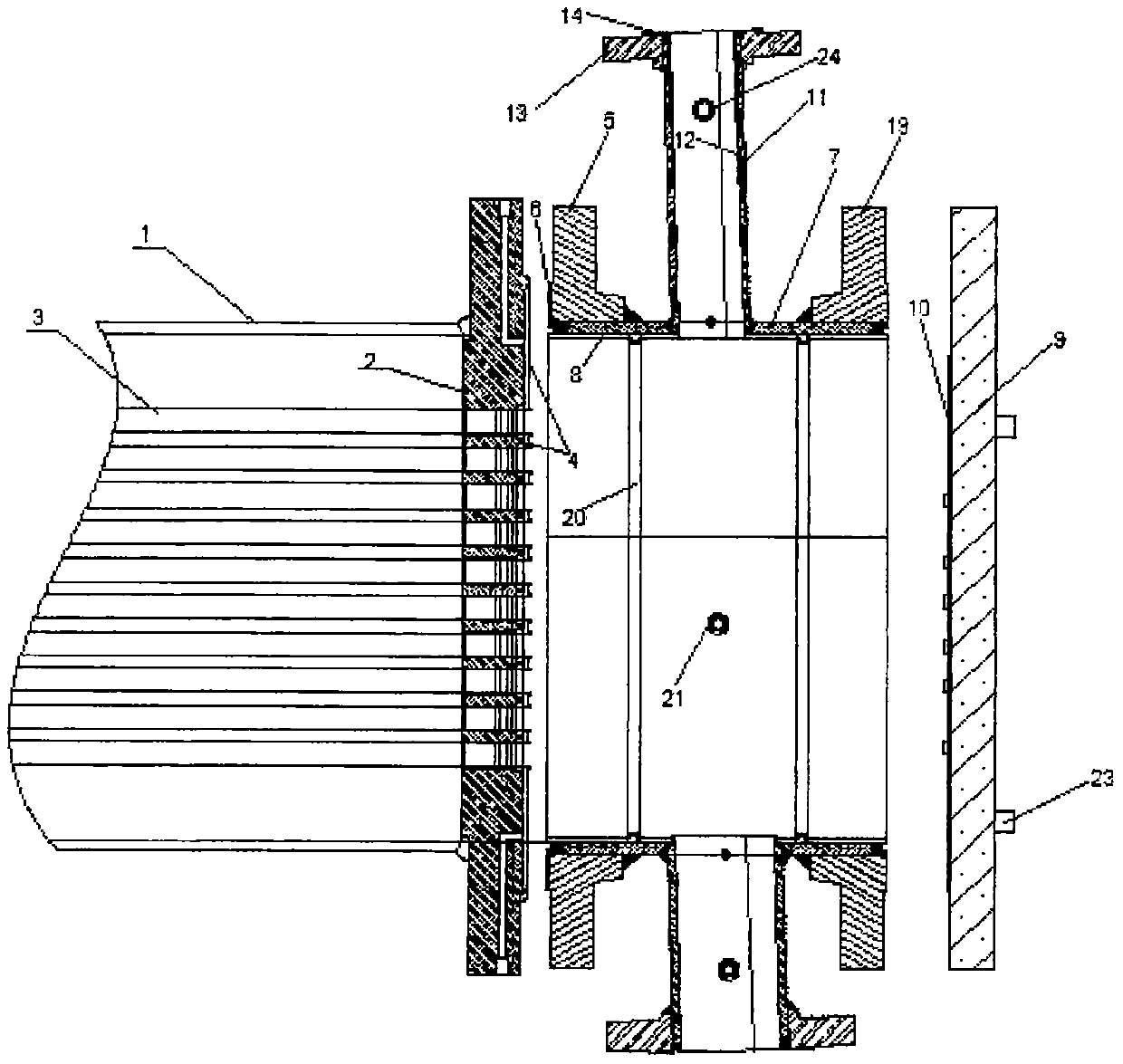

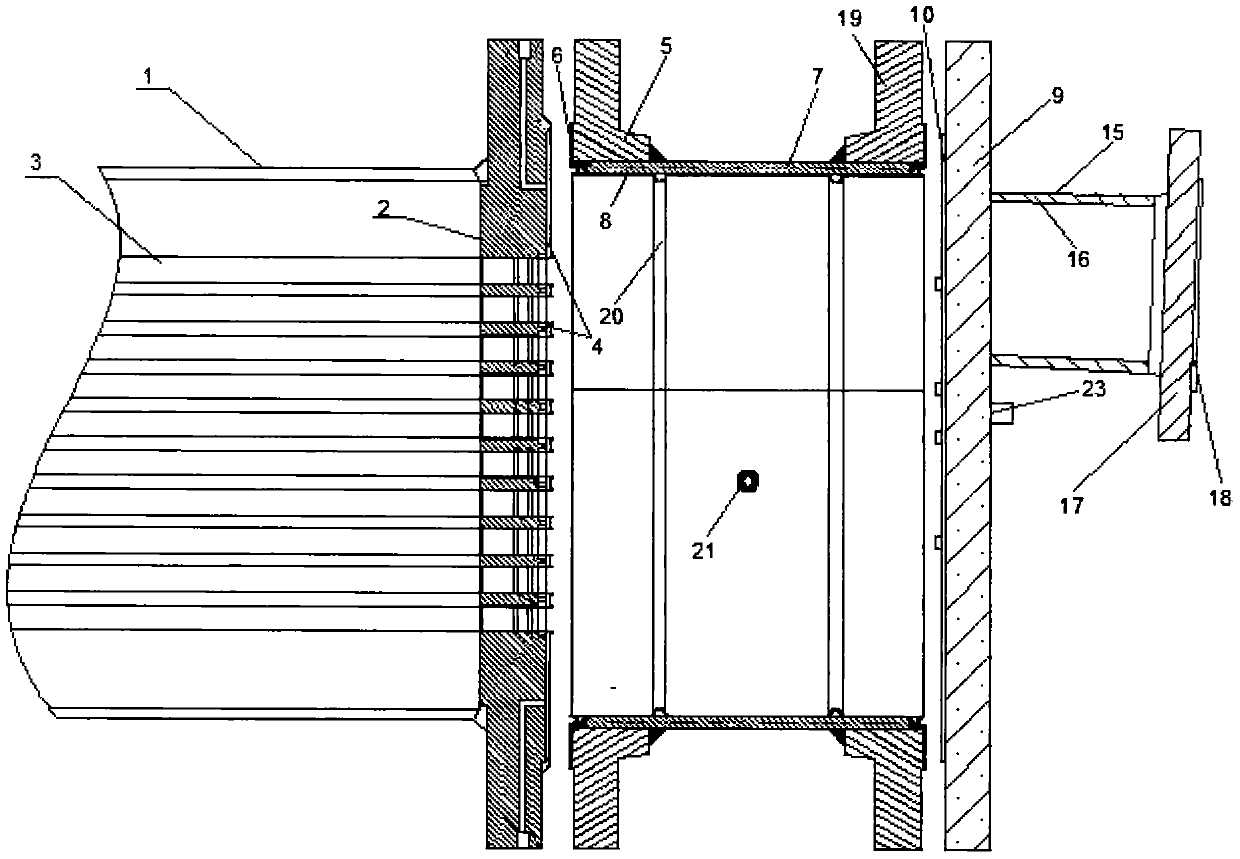

[0021] like figure 1 As shown, the heat exchanger with a loose lining structure of the present invention includes a main body part and a tube box part; the main body part includes a shell 1, a tube sheet 2 and a heat exchange tube 3, and the tube sheet 2 is vertically arranged at one end of the shell 1, and the heat exchange tube 3 is vertically fixed on the tube plate 2 in the shell 1; the tube box part includes a tube box shell 7, and the tube box The tank shell 7 is provided with a tube box flange 5 on the first end conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com