Preparation method of seawater corrosion-resistant high-safety plastic sprayed soil

A high-safety, seawater-resistant technology, applied in the field of anti-corrosion, can solve the problems of durability failure and damage of structures, and achieve the effect of improving anti-corrosion, improving durability, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A high-safety sprayed clay resistant to seawater corrosion, including the following percentages of raw materials:

[0032] Silicate 23%, dolomite 21%, graphene 5%, matte glaze 11%, crack glaze 10%, kaolin 7%, emulsifier 3.5%, epoxy resin 13%, silicon powder 5.25%, nickel powder 1.25 %.

Embodiment 2

[0034] A high-safety sprayed clay resistant to seawater corrosion, including the following percentages of raw materials:

[0035] Silicate 17%, Dolomite 19%, Graphene 6%, Matte Glaze 9%, Crackle Glaze 9%, Kaolin 8%, Emulsifier 5%, Epoxy Resin 19%, Silicon Powder 6%, Nickel Powder 2 %.

Embodiment 3

[0037] A high-safety sprayed clay resistant to seawater corrosion, including the following percentages of raw materials:

[0038] Silicate 18%, dolomite 20%, graphene 7%, matte glaze 10%, crack glaze 11%, kaolin 6%, emulsifier 4.5%, epoxy resin 14%, silicon powder 7%, nickel powder 2.5 %.

[0039] Specifically, dolomite contains 6% ferric oxide, which increases the electrical conductivity of the porcelain body, applies spraying to the ceramic field, reduces the use of chemical materials such as paint, reduces consumption, and is environmentally friendly. The matte glaze includes 40% ferric oxide. Feldspar, 15% barium carbonate, 15% calcium, 20% quartz, 10% kaolin, can be used to make matte glazes of different colors, cracked glazes include 40% nepheline, 35% Potassium feldspar, 15% calcium, and 10% kaolin play a decorative role.

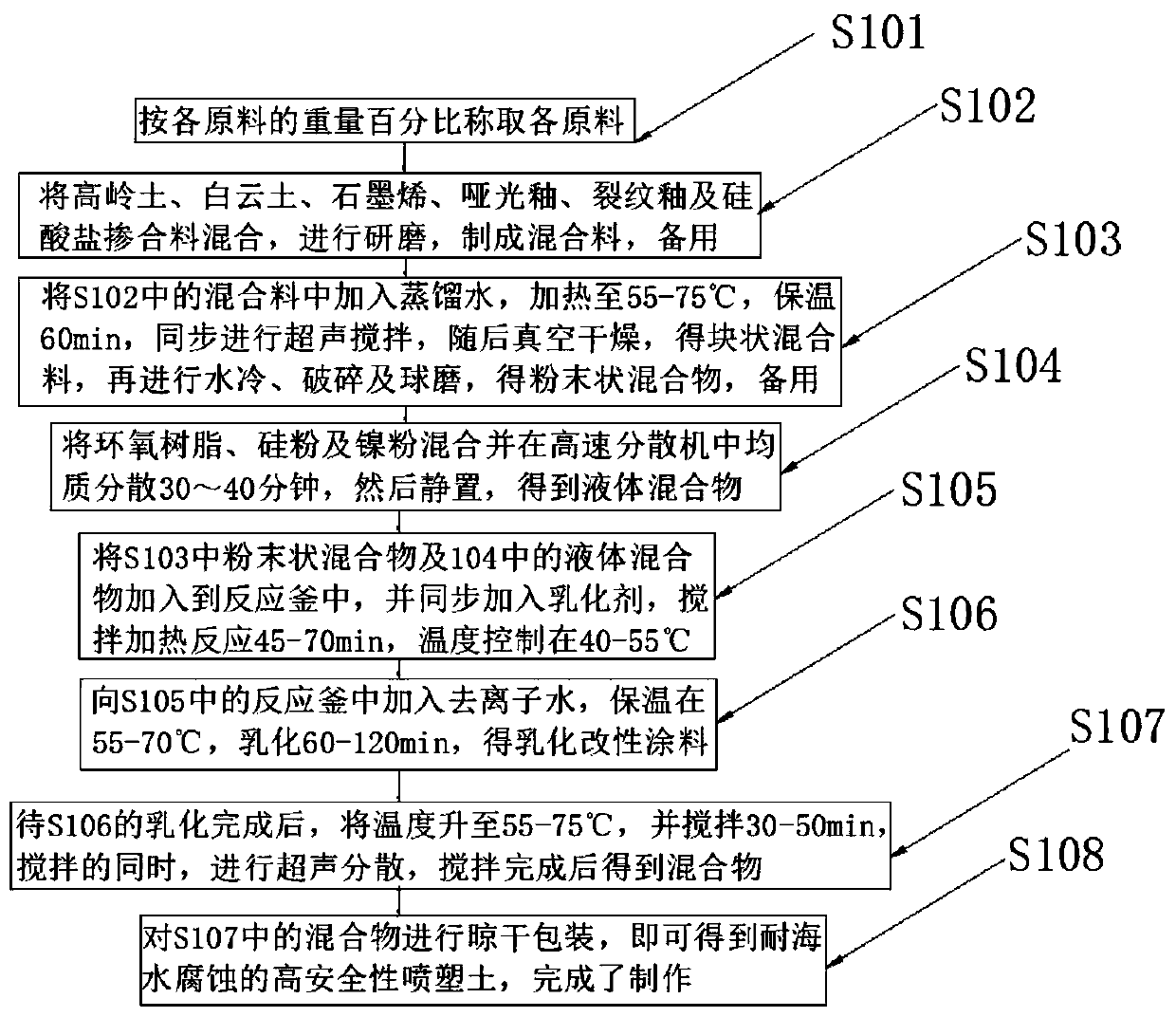

[0040] like figure 1 As shown, according to the embodiment of the present invention, a method for preparing high-safety plastic-sprayed clay resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com