Carriage steel plate and preparation method thereof and carriage

A carriage board and carriage technology, applied in chemical instruments and methods, vehicle parts, transportation and packaging, etc., can solve problems such as inability to use for a long time, poor wear resistance of coating, corrosion of steel substrate, etc., and achieve good welding performance, good Abrasion resistance and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

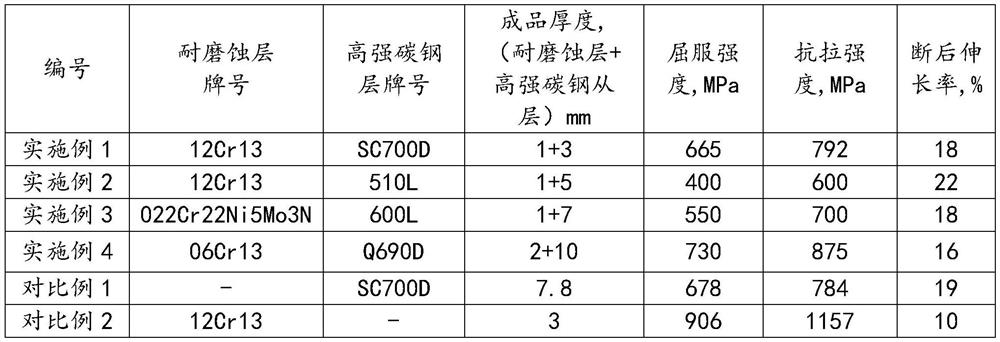

[0061] Embodiment 1 provides a steel plate for a carriage and a preparation method thereof. The steel plate for a carriage includes a wear-resistant steel layer made of 12Cr13 and a high-strength carbon steel layer made of SC700D.

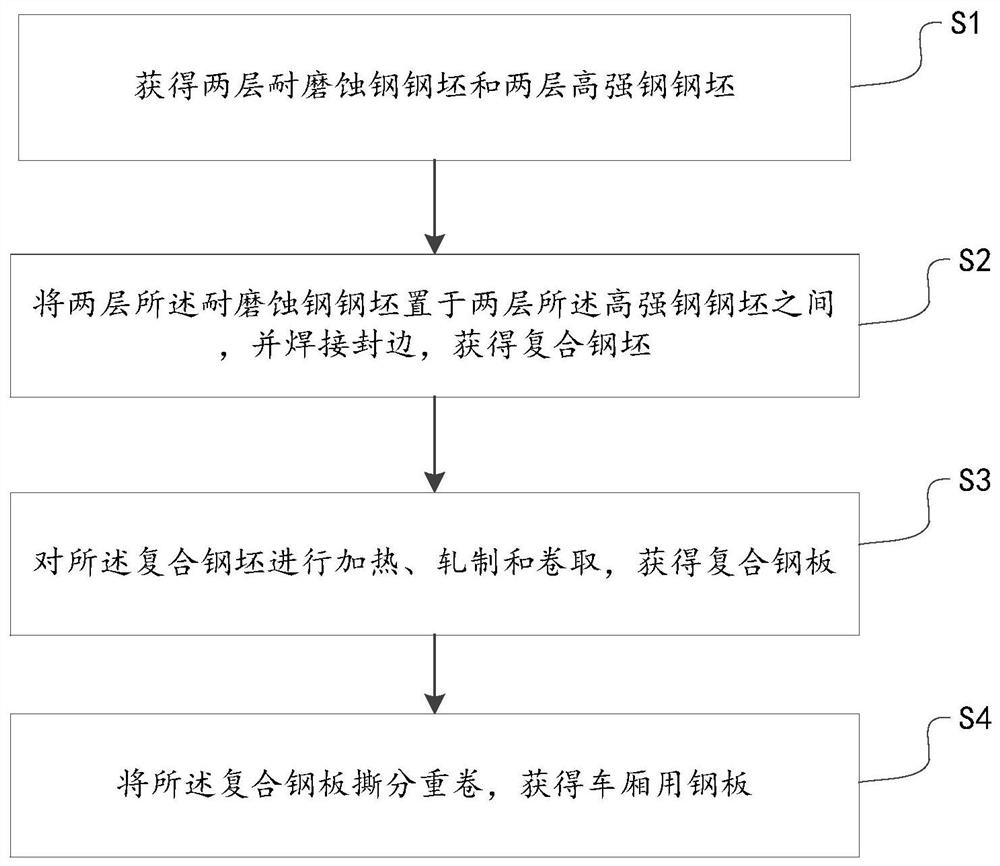

[0062] The preparation method of the steel plate for the carriage comprises the following steps:

[0063] Step 1, place two layers of wear-resistant steel billets made of 12Cr13 between two layers of high-strength carbon steel billets made of SC700D, wherein the metal surfaces of the wear-resistant steel billet and the high-strength carbon steel billet are directly abutted without leaving a gap , A release agent is laid between two layers of wear-resistant steel billets to form a composite billet with a thickness of 200mm×width 1700mm×length 8000mm. Among them, the thickness of the wear-resistant steel billet 12Cr13 is 25mm, and the thickness of the high-strength carbon steel billet SC700D is 75mm.

[0064] Then, the composite steel billet is weld...

Embodiment 2

[0069] Embodiment 2 provides a steel plate for a carriage and a preparation method thereof. The steel plate for a carriage includes a wear-resistant steel layer made of 12Cr13 and a high-strength carbon steel layer made of 510L.

[0070] The preparation method of the steel plate for the carriage comprises the following steps:

[0071] Step 1. Place two layers of 12Cr13 wear-resistant steel billet between two layers of 510L high-strength carbon steel billet, wherein the metal surfaces of the wear-resistant steel billet and the high-strength carbon steel billet are directly in contact without leaving a gap , A release agent is laid between two layers of wear-resistant billets to form a composite billet with a thickness of 216mm×width 1800mm×length 5000mm. Among them, the thickness of the corrosion-resistant billet 12Cr13 is 18mm, and the thickness of the high-strength carbon steel billet 510L is 90mm.

[0072] Then, the composite steel billet is welded and edge-sealed by vacuum...

Embodiment 3

[0077] Embodiment 3 provides a steel plate for a carriage and a preparation method thereof. The steel plate for a carriage includes an abrasion-resistant steel layer made of 022Cr22Ni5Mo3N and a high-strength carbon steel layer made of 600L.

[0078] The preparation method of the steel plate for the carriage comprises the following steps:

[0079]Step 1, place two layers of wear-resistant steel billets made of 022Cr22Ni5Mo3N between two layers of high-strength carbon steel billets made of 600L, wherein the metal surfaces of the wear-resistant steel billet and the high-strength carbon steel billet are directly abutted without leaving a gap , A release agent is laid between two layers of wear-resistant billets to form a composite billet with a thickness of 224mm×width 2000mm×length 9000mm. Among them, the thickness of the wear-resistant steel billet 022Cr22Ni5Mo3N is 14mm, and the thickness of the high-strength carbon steel billet 510L is 98mm.

[0080] Then, the composite stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com