Pore pressure measuring device and system

A measuring device and pore technology, which is applied in the direction of measuring device, suspension and porous material analysis, instruments, etc., can solve the problems of reduced measurement accuracy, reduced accuracy, and inability to measure pressure signals, so as to improve the measurement accuracy and improve the Application capability, effect of high measurement resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

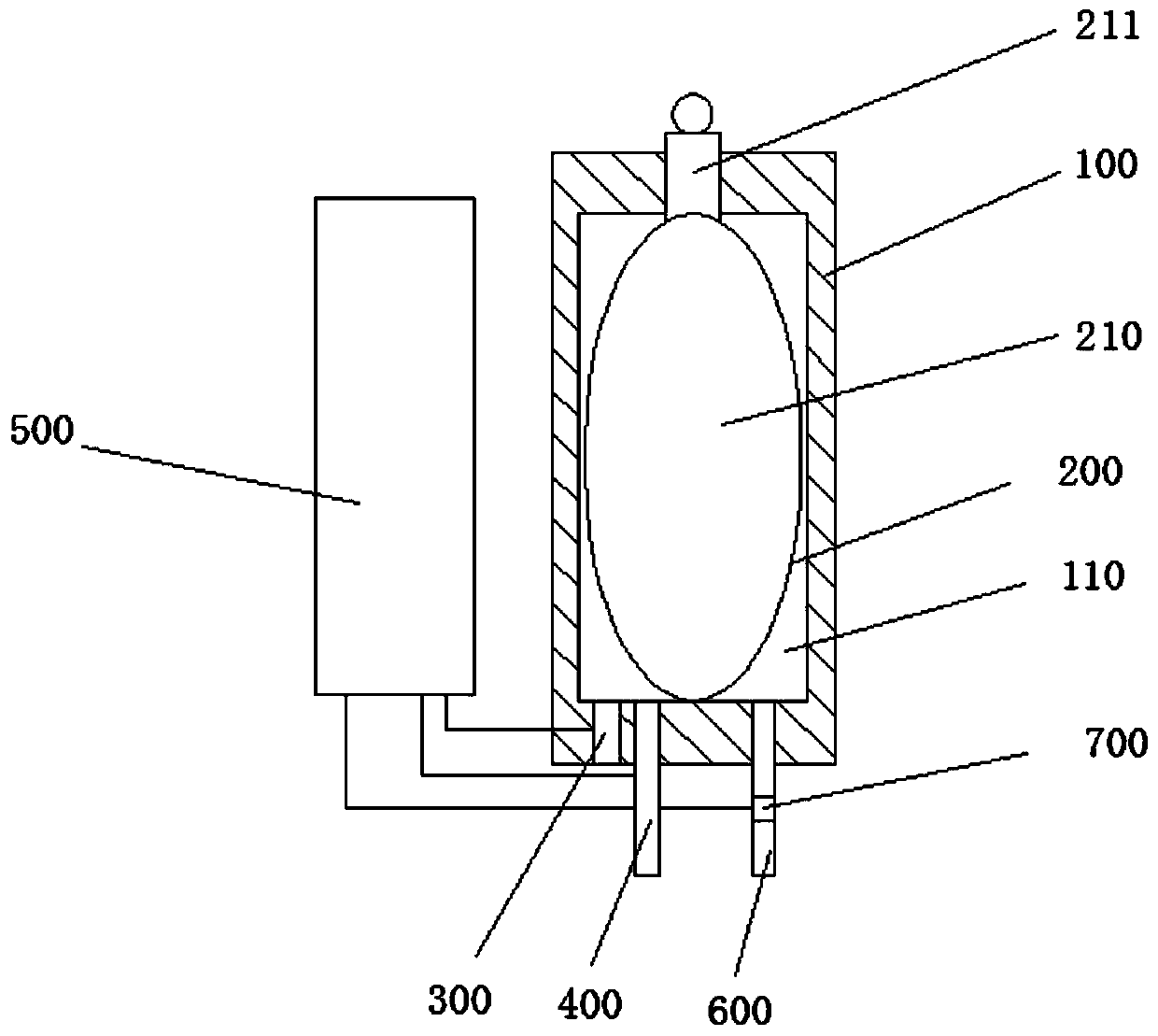

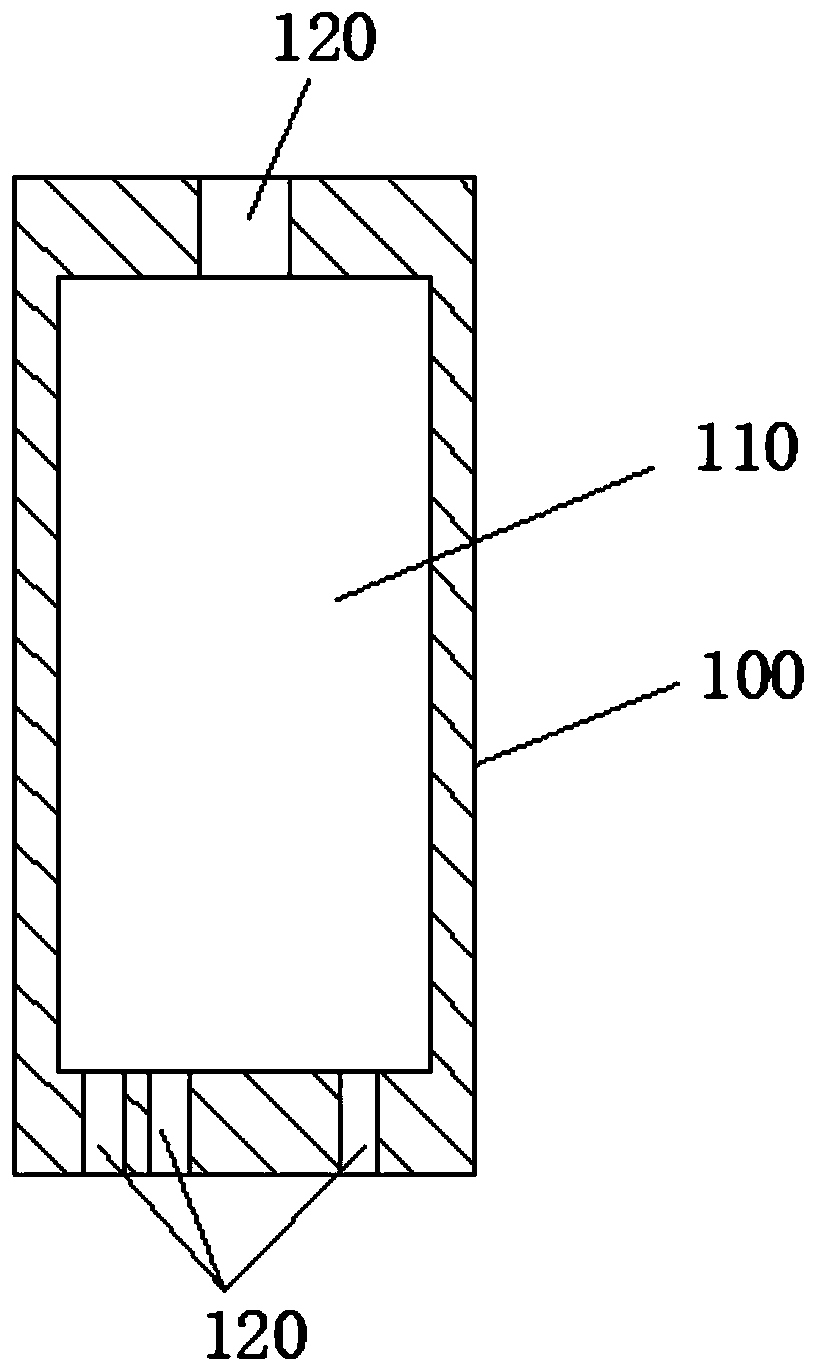

[0039] Such as figure 1 and figure 2 As shown, the pore pressure measurement device provided by the present invention includes: a first housing 100 , an inflatable pressure stabilizing assembly 200 , a first sensor 300 , a second sensor 400 and a data acquisition control module 500 .

[0040] The interior of the first housing 100 is provided with a back pressure chamber 110; the inflatable pressure stabilizing assembly 200 is arranged in the back pressure chamber 110, and the volume of the inflatable pressure stabilizing assembly 200 is changed by inflating the inflatable pressure stabilizing assembly 200, thereby adjusting The working pressure range in the back pressure chamber 110;

[0041] The first sensor 300 is arranged inside the first casing 100 to detect the pressure in the back pressure chamber 110;

[0042] One end of the second sensor 400 protrudes into the back pressure chamber 110 in the first housing 100, and the other end protrudes out of the first housing 10...

Embodiment 2

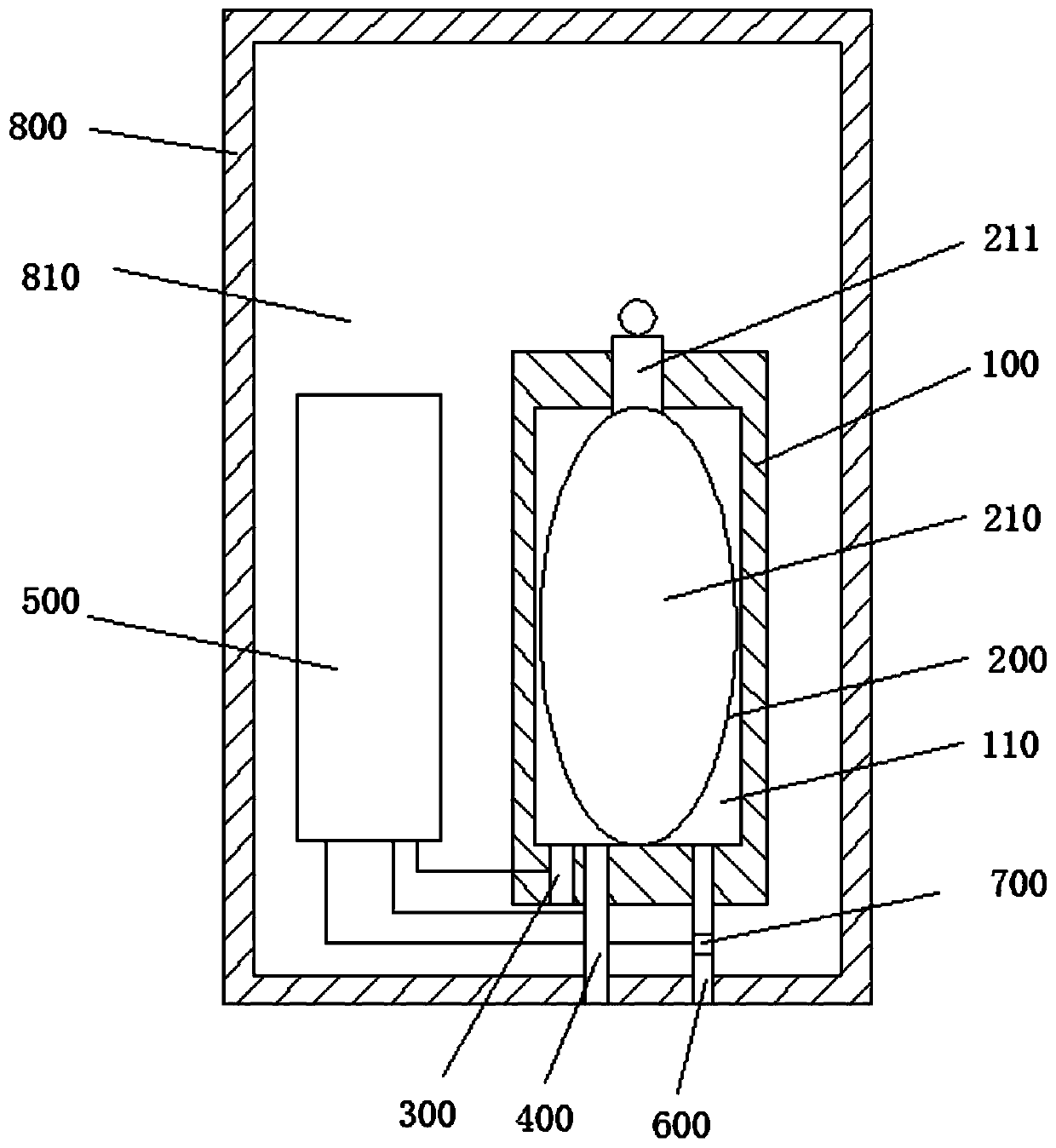

[0063] An embodiment of the present invention provides a pore pressure measurement system, which includes a data monitoring device, and the pore pressure measurement device provided in one of the above-mentioned embodiments.

[0064] Since the structure of the pore pressure measuring device has been described in Embodiment 1, it will not be repeated in this embodiment;

[0065] The above data monitoring device is electrically connected to the data acquisition control module through a signal line, and the data monitoring device can collect the basic pressure value, pressure difference value and pore pressure value calculated by the data acquisition control module, which is convenient for staff to monitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com