Cooling fan speed setting method suitable for temperature closed-loop adjustment of power electronic device

A power electronic device, temperature closed-loop technology, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve problems such as poor reliability, failure of power electronic devices, failure of heat dissipation system, etc., to improve reliability and prevent The effect of thermal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

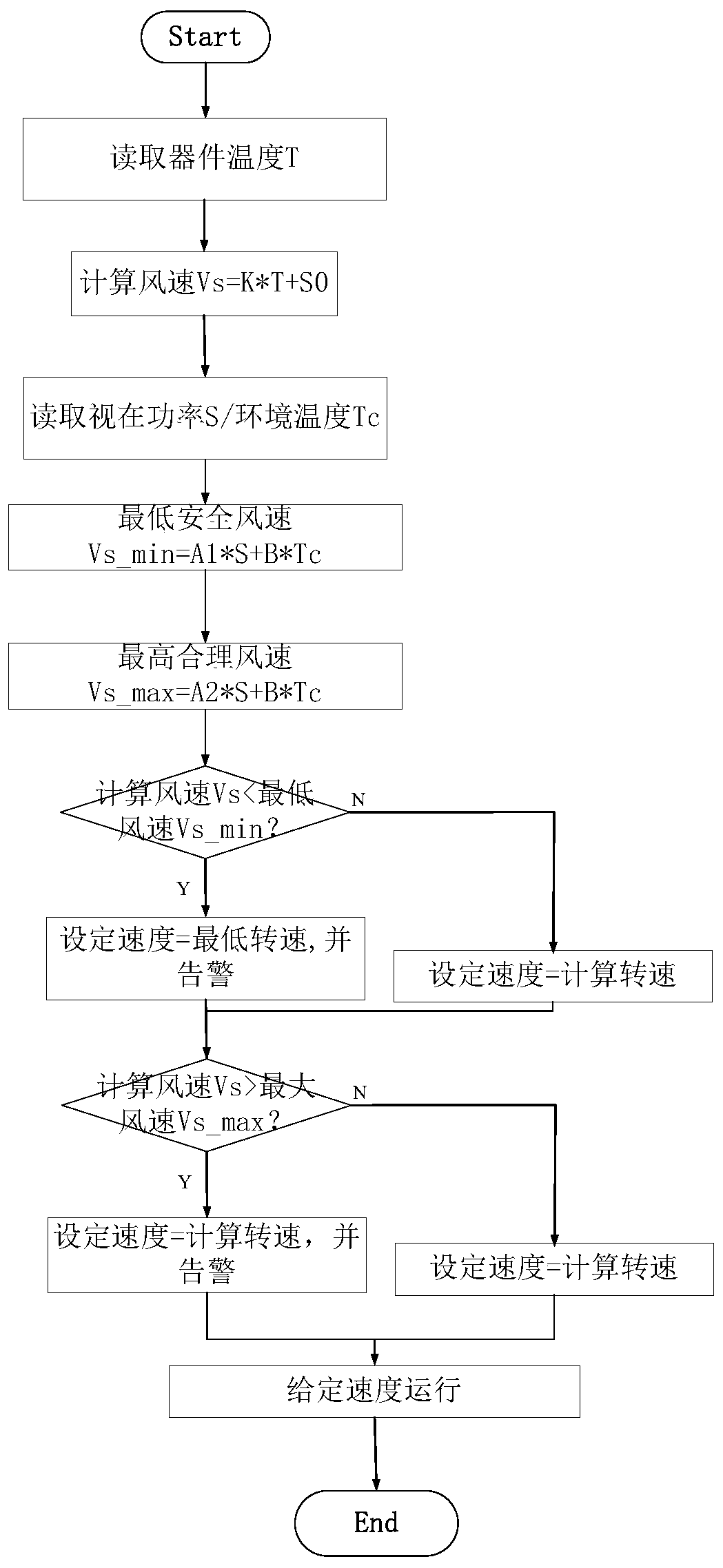

[0014] see figure 1 As shown, a power electronic converter cooling system is taken as an example to describe a specific implementation of the present invention.

[0015] The converter controller first reads the internal temperature T of the power electronic converter module, according to the temperature and wind speed linear correlation formula (Vs=K*T+S0, V is the given wind speed of the cooling system, K is the temperature and wind speed correlation coefficient, S0 Calculate the wind speed Vs for the basic wind speed when the temperature is 0°C.

[0016] Then, the converter controller reads the ambient temperature Tc and the apparent power S of the current power electronic converter device, and sets the relationship according to the minimum safe wind speed and the ambient temperature and apparent power of the device (Vs_min=A1*S+B* Tc, where Vs_min is the given value of the minimum safe wind speed, A1 is the correlation coefficient of the minimum safe wind speed of the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com