Friction-piezoelectric-electromagnetic composite energy harvester for low-speed rotary motion

A rotary motion and composite technology, applied in the direction of friction generators, piezoelectric effect/electrostrictive or magnetostrictive motors, electric components, etc., can solve the problem of low output power, low energy collection efficiency, and single energy capture method and other issues, to achieve the effect of improving output power and energy conversion efficiency, simple and compact structure, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

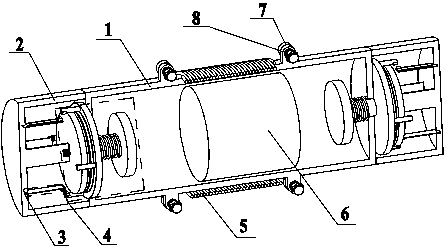

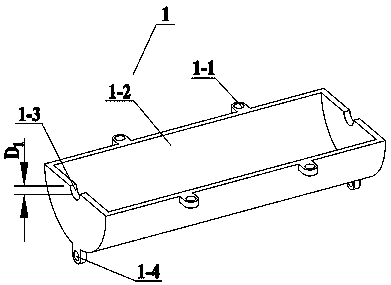

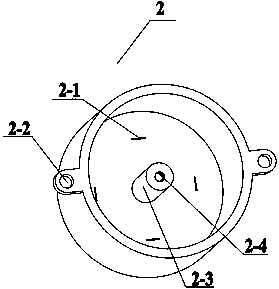

[0025] combine Figure 1~Figure 9 Describe this implementation mode:

[0026] This embodiment provides a specific implementation of a low-speed rotational motion-oriented friction-piezoelectric-electromagnetic composite energy harvester. The friction-piezoelectric-electromagnetic composite energy harvester facing low-speed rotation is composed of a semicircular outer shell 1, an end cover 2, a piezoelectric power generation unit 3, a friction power generation component 4, an electromagnetic coil 5, a cylindrical magnet 6, bolts 7. Composed of nuts 8; the semicircular outer casing 1 is fixed by means of bolts 7 and nuts 8 through threaded connections, and the end cover 2 is fixed on the semicircular outer casing by means of bolts 7 and nuts 8 through threaded connections The two ends of the body 1, the piezoelectric power generation unit 3 is fixed on the square groove 2-1 by gluing, the friction power generation component 4 is supported by the spring 4-2 and the threaded hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com