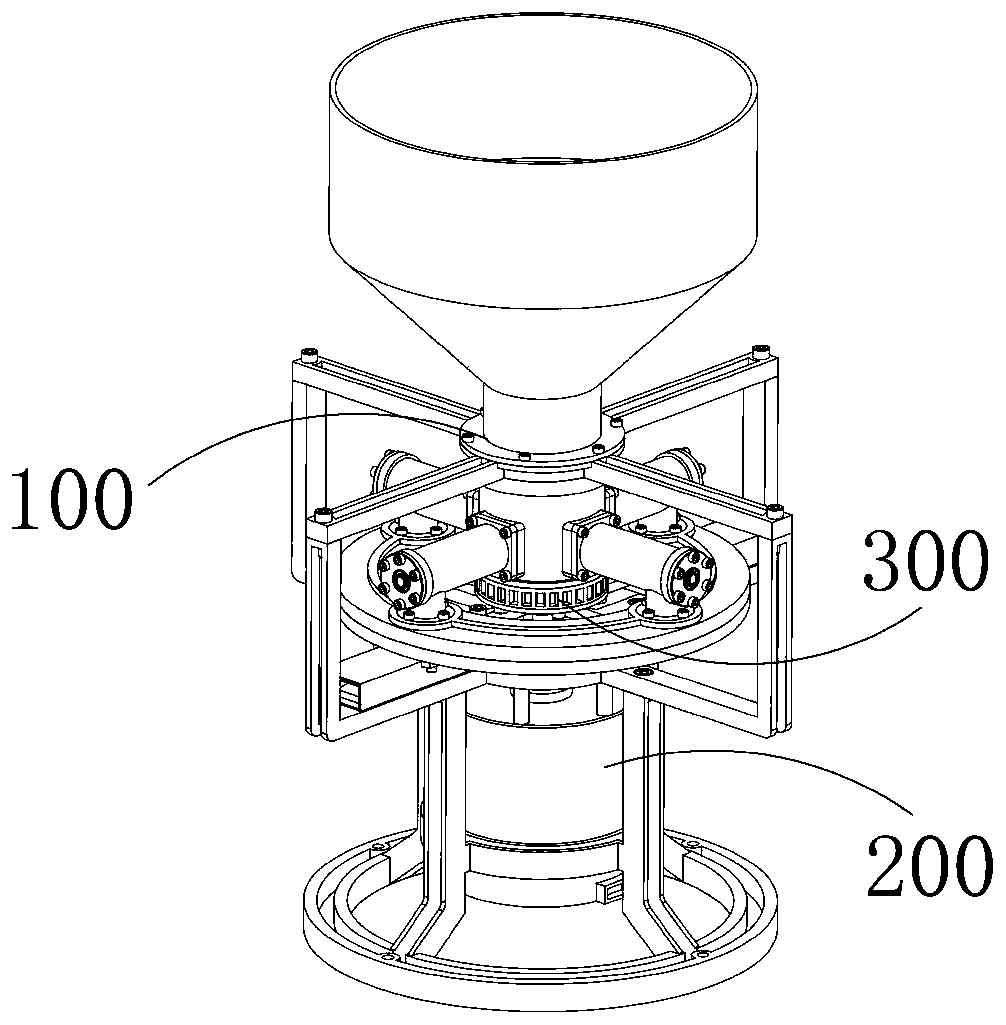

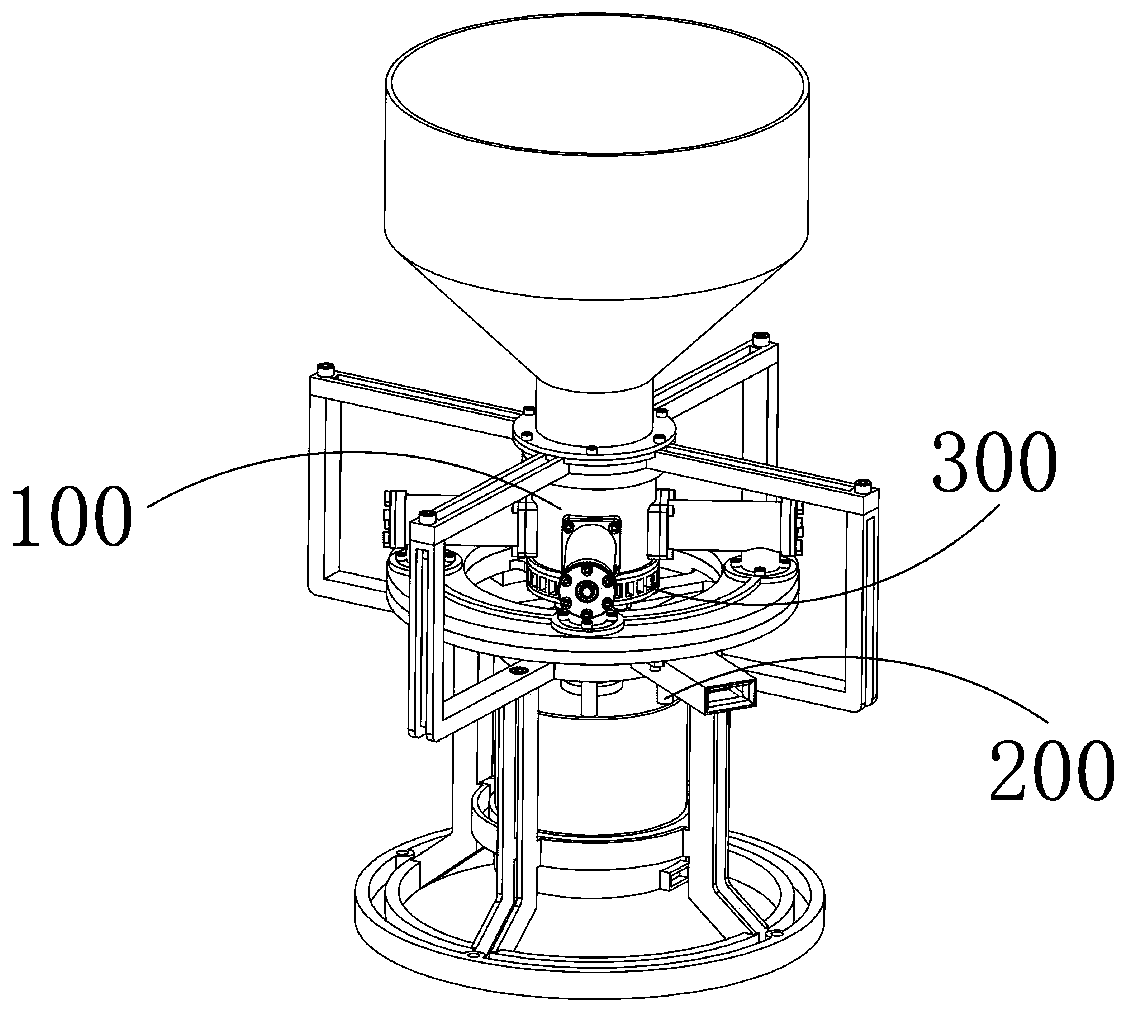

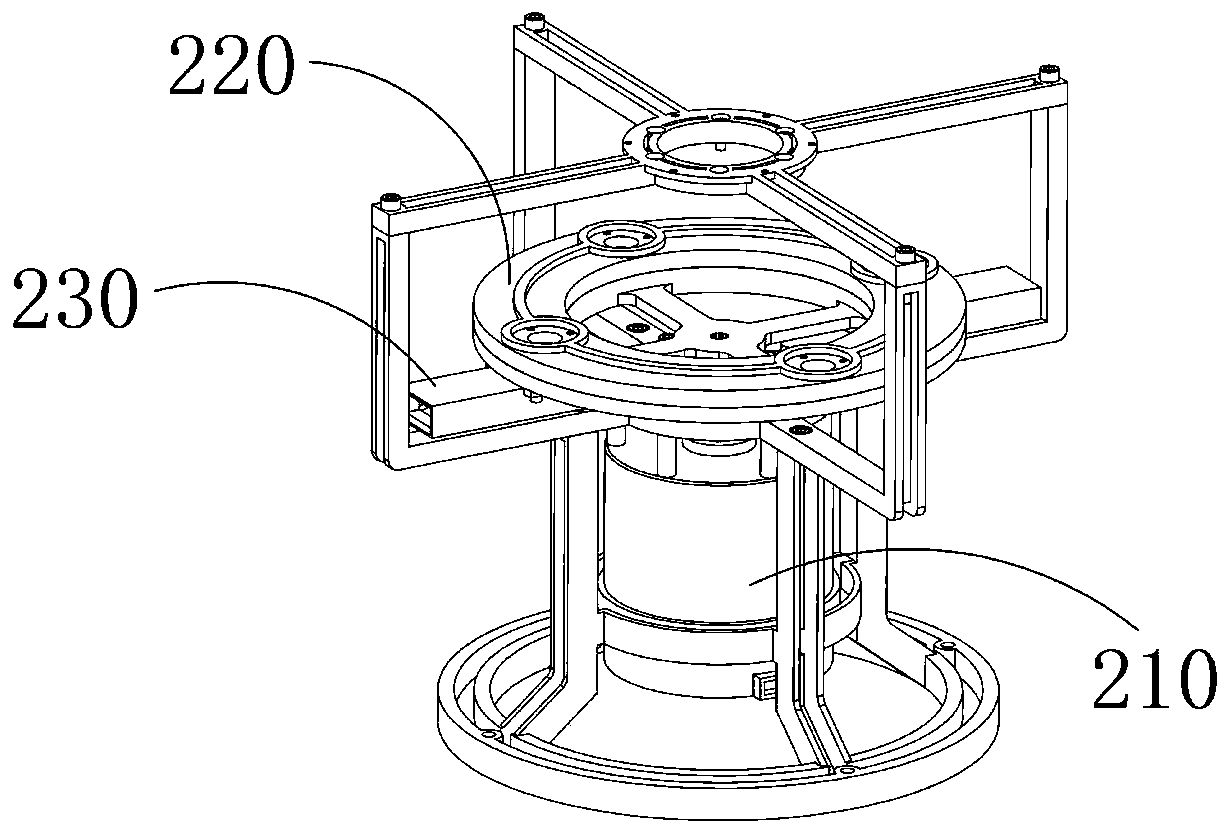

Centrifugal granular fertilizer spreader

A granular fertilizer and centrifugal technology, applied in the field of agricultural machinery, can solve the problems of staying, reducing labor intensity, uneven fertilizer application, etc., and achieve the effect of smooth fertilizer spreading process, improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention adopts the high-speed rotating centrifugal throwing method to throw the granular fertilizer. The advantage is that the staff only need to pour the granular fertilizer into the feeding funnel, and the granular fertilizer can be evenly spread outward through the auger mechanism and the centrifugal throwing device. Spreading, the entire spreading process is fully automated, without manual operation by staff, which greatly reduces labor intensity and improves work efficiency. At the same time, the auger feeding device and the centrifugal spreading device share the same power source, and the power deceleration transmission device is used between the two The power transmission prevents the auger feeding device from feeding too fast and blocking the material receiving hole, and the fertilizer spreading process is smoother. In addition, the four groups of cavity walls of the throwing cylinder are all equipped with dispersing protrusions, which can The ferti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap