Vegetable market garbage pulverizing machine

A pulverizer, vegetable market technology, applied in dryers, presses, food science and other directions, can solve problems such as single function of pulverizers, increased difficulty in garbage disposal in vegetable markets, and inability to meet the needs of cleaning, dehydration and drying. , to achieve the effect of reducing physical exertion and reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

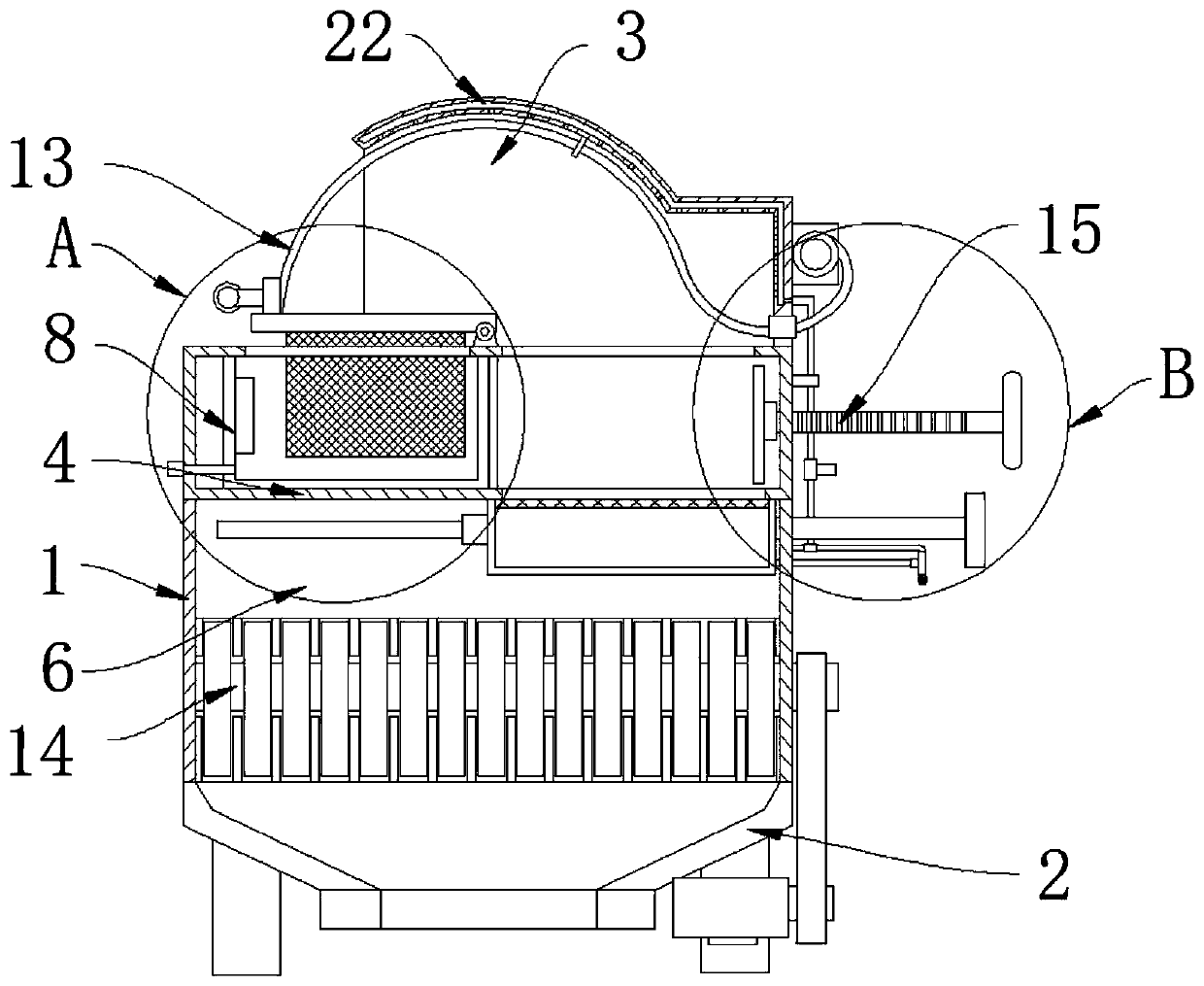

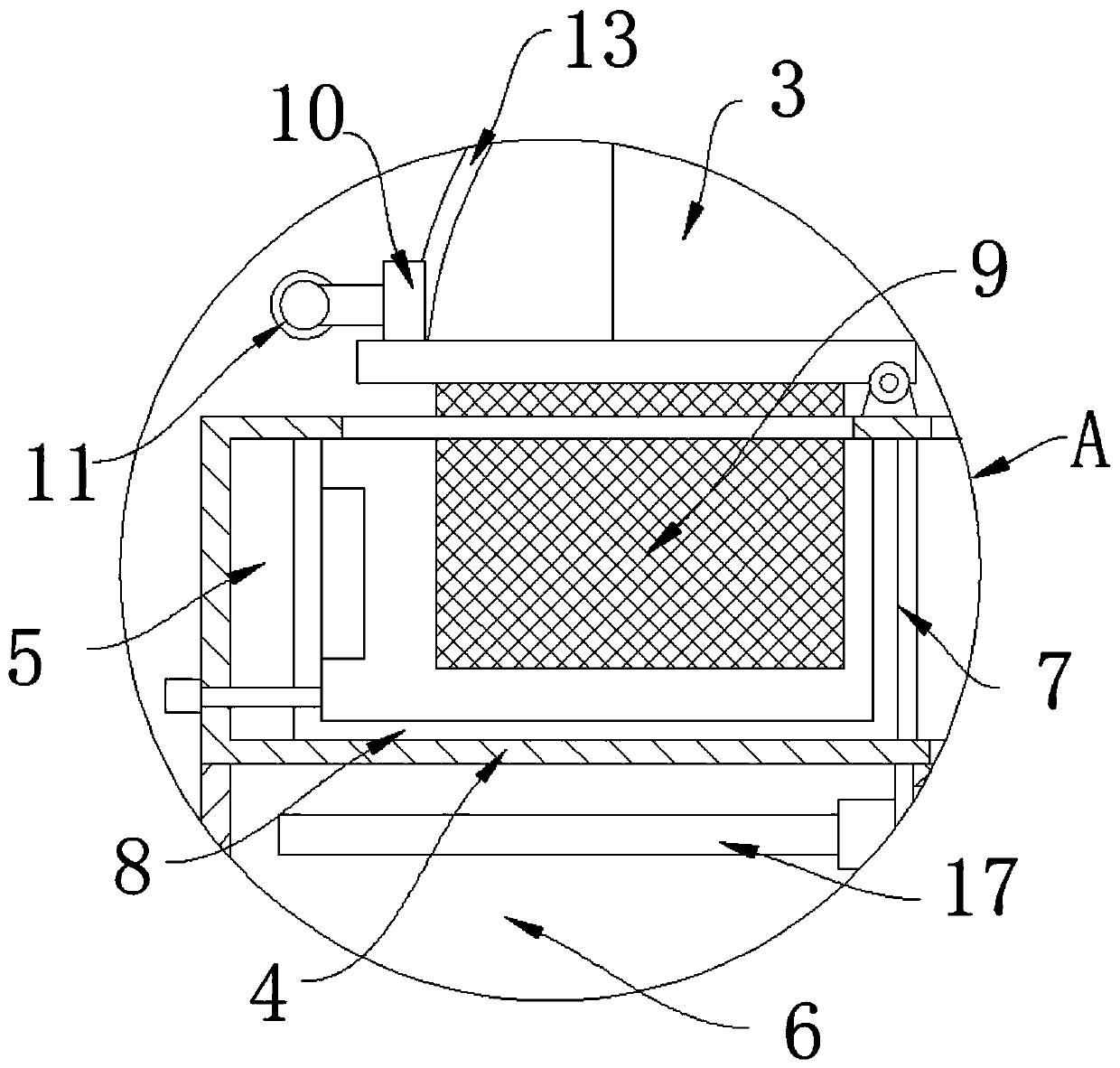

[0024] A garbage shredder for a vegetable market, comprising a shredder body 1, a shredder body 1, a collection bottom hopper 2 arranged at the bottom of the shredder body 1, an auxiliary cover 3 installed on the upper part of the shredder body 1, and a horizontal Partition 4, the interior of the pulverizer body 1 is separated by a horizontal partition 4 to form an upper cleaning and dehydration chamber 5 and a lower pulverization chamber 6, and the cleaning and dehydration chamber 5 is connected with the pulverization chamber 6, and the lower surface of the collecting bottom hopper 2 is fixed Connected with a support column, the pulverizing chamber 6 of the pulverizer body 1 is provided with a pulverizing knife roller 14 driven by a motor, and the number of pulverizing knife rollers 14 is at least two, and they rotate in opposite directions;

[0025] The middle part of the cleaning dehydration chamber 5 is provided with a vertical partition 7, the upper surface of the horizont...

Embodiment 2

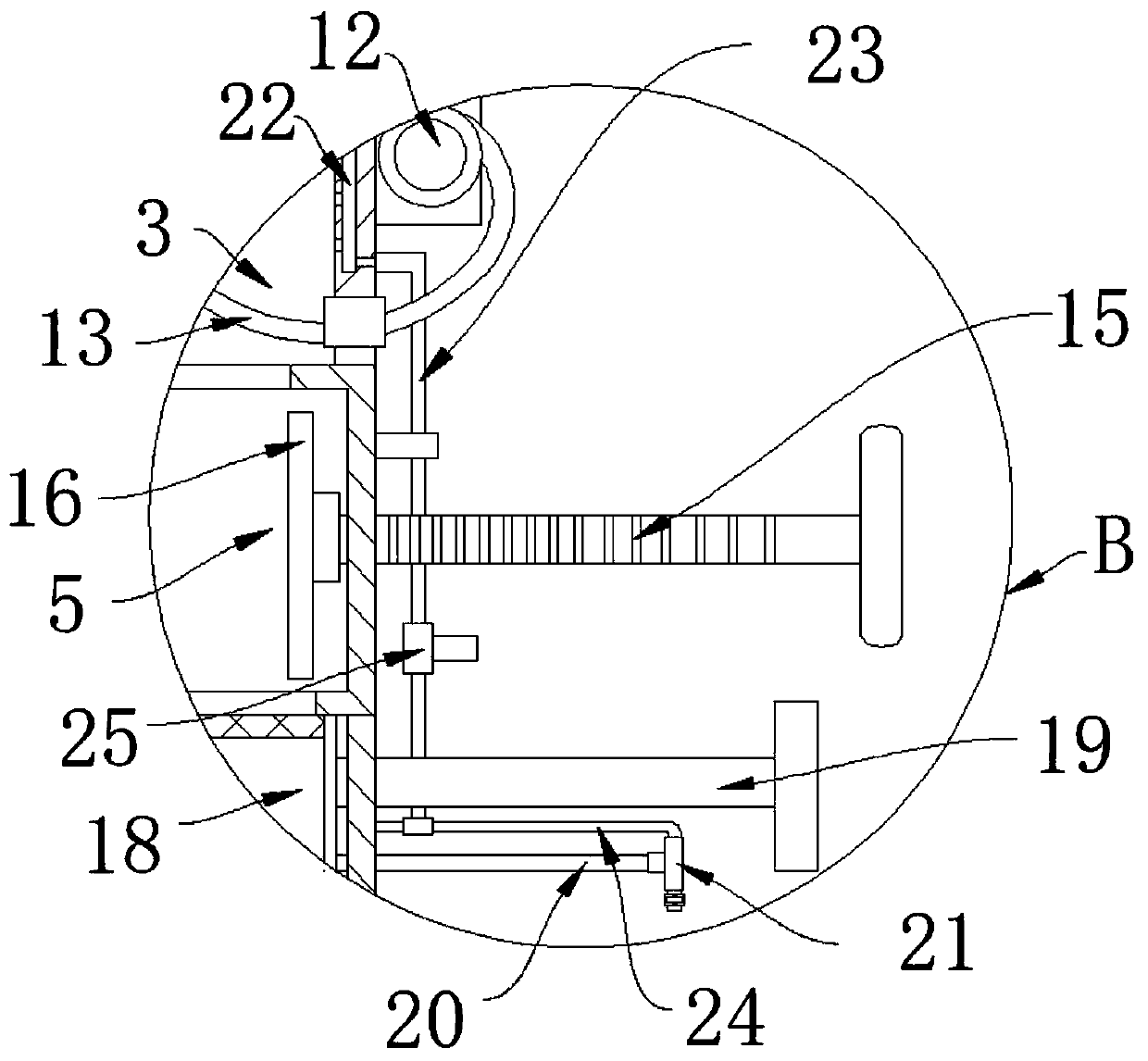

[0031] Different from Embodiment 1, the upper surface of the auxiliary cover 3 is shaped as an arc, and the arc is adapted to the clockwise rotation track of the cleaning screen frame. The inside of the auxiliary cover 3 is embedded with an air flow pipe 22, and the surface of the air flow pipe 22 A number of airflow holes blowing to the inside of the auxiliary cover 3 are provided. The airflow pipe 22 extends to the right side of the auxiliary cover 3 and communicates with the vertical pipe 23. The bottom of the vertical pipe 23 is fixedly connected with an air delivery hose 24. The air delivery hose 24 is fixedly connected with tee 21, and the middle part of vertical pipe 23 is provided with hot blast inlet tee 25, and hot blast inlet tee 25 is communicated with hot air blower by hot air inlet pipe.

[0032] In this embodiment, by setting the hot air inlet tee 25 to connect the hot air blower, the dry hot air can enter the airflow pipe 22 and the drain pipe 20 from the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com