Soft key vacuum adsorption calibration assembly equipment

A technology for vacuum adsorption and assembly equipment, which is applied in the field of musical instrument soft key assembly. It can solve the problems of the positioning rubber column leaking into the assembly hole, difficulty in ensuring product quality, and easy tilting, so as to avoid missing assembly, good assembly effect, and work. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

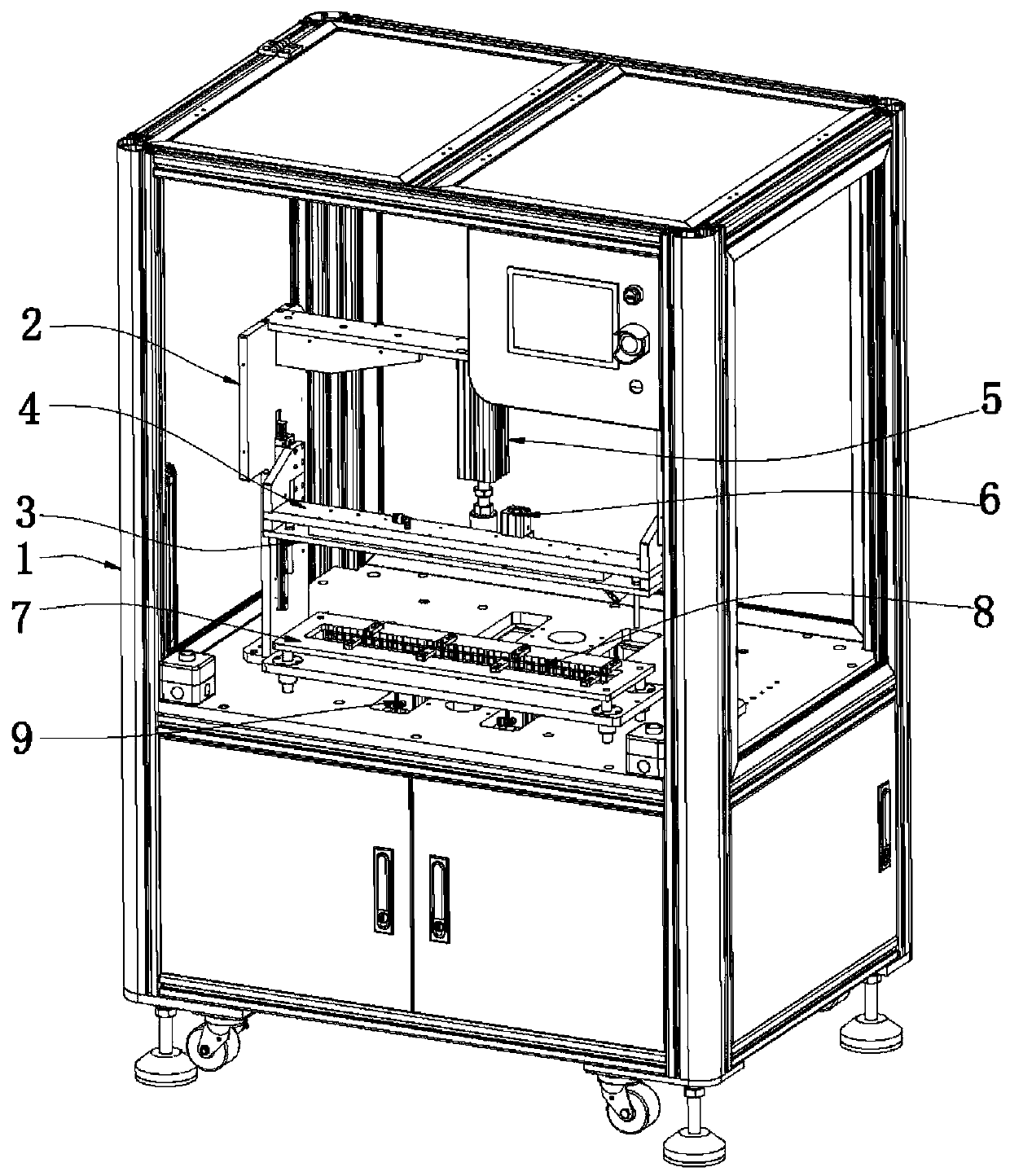

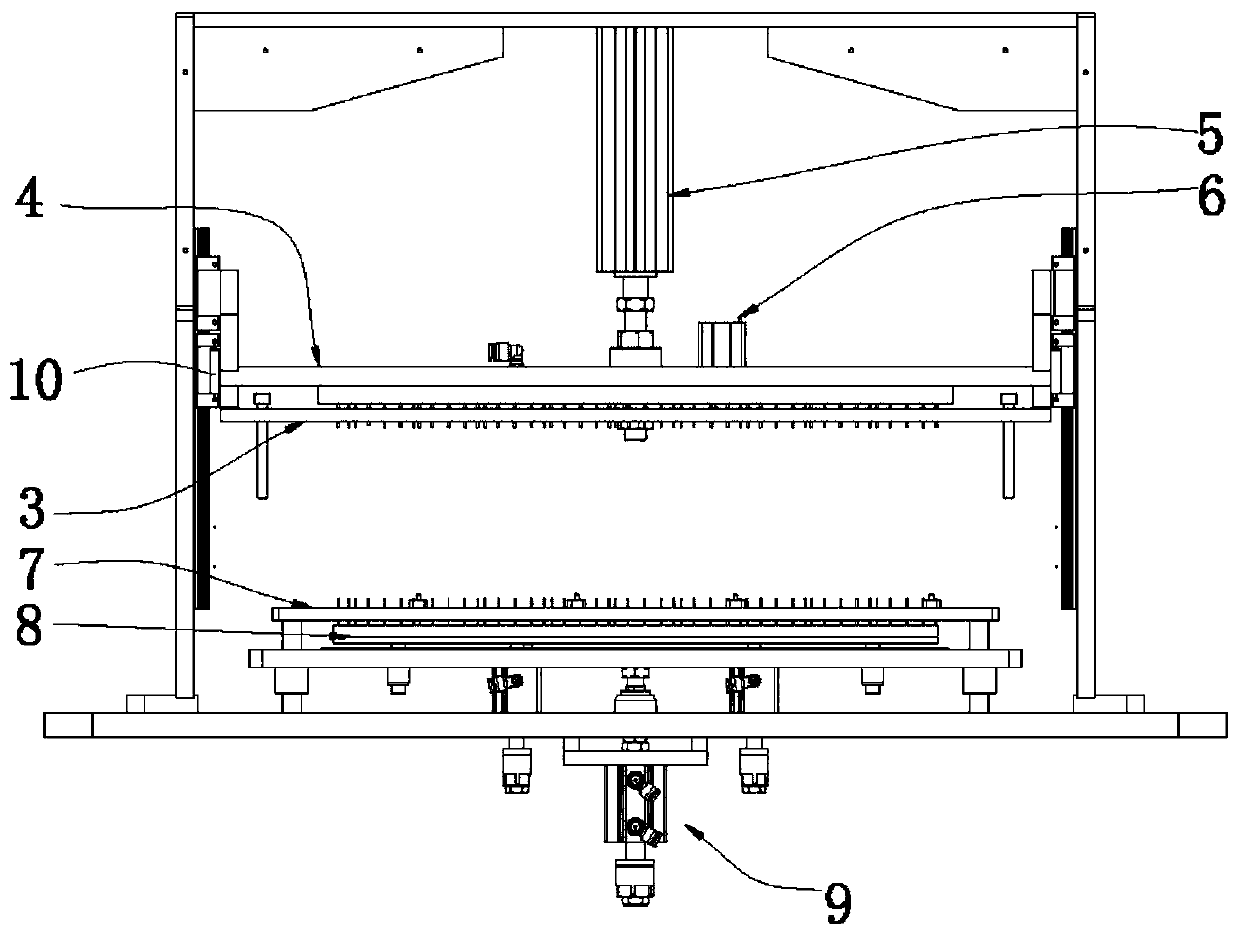

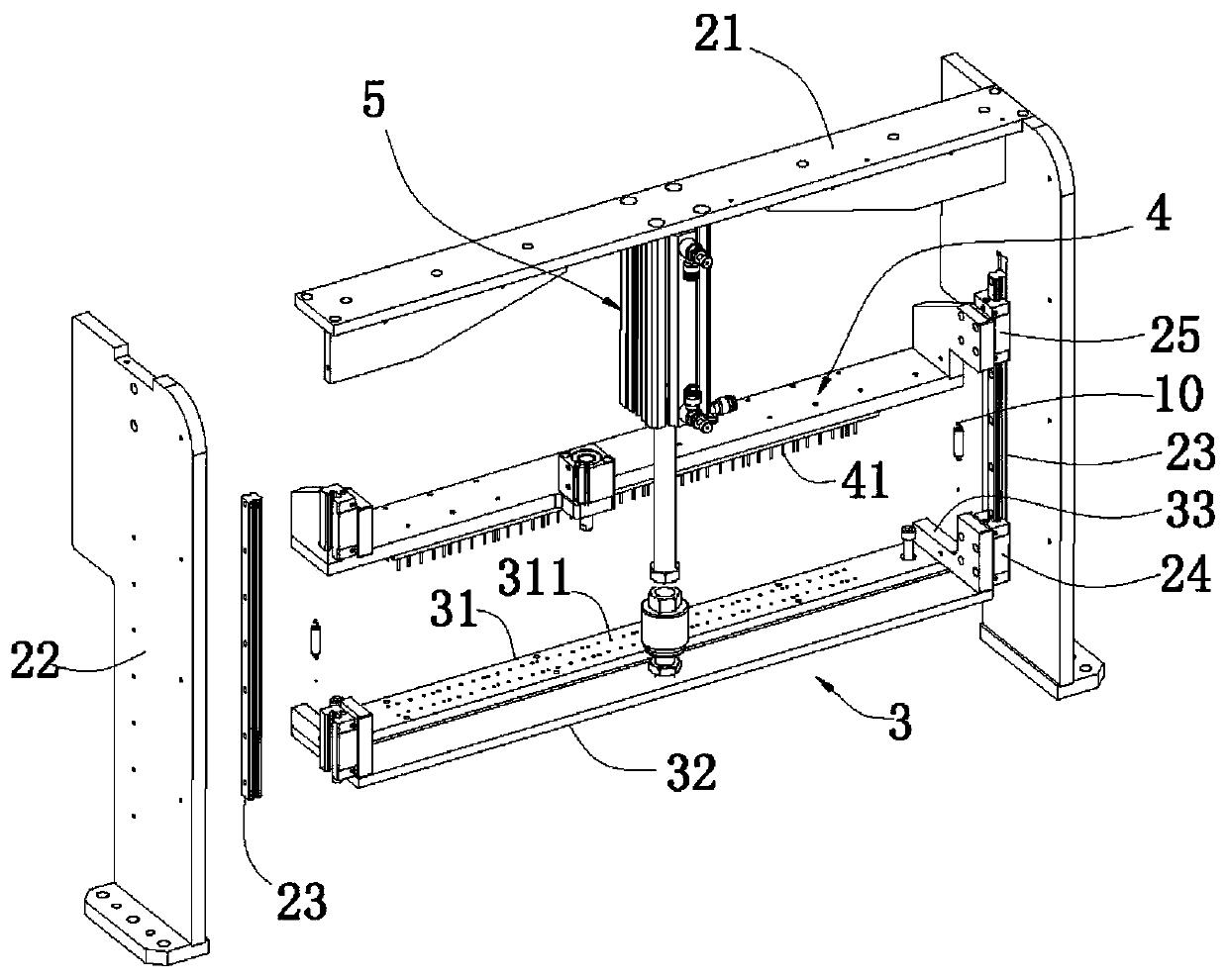

[0023] Examples, see Figure 1 to Figure 5 , a soft button vacuum adsorption calibration assembly equipment provided in this embodiment, which includes a frame 1, a gantry frame 2, a pressure plate 3, an adsorption plate 4, a lifting drive device 5, an up and down drive device 6, a product positioning seat 7, and a thimble plate 8 and thimble driving device 9.

[0024] The gantry 2 is arranged on the workbench of the frame 1, and the position below the crossbeam 21 of the corresponding gantry 2 of the product positioning seat 7 is arranged on the workbench. The inside of the column 22 of the gantry 2 is provided with a linear guide rail 23. The two ends of the pressure plate 3 are movably arranged on the linear guide rail 23 through the sliding seat 24, the lifting drive device 5 is arranged on the beam 21, and can drive the pressure plate 3 to perform lifting action, and the adsorption plate 4 is located on the side of the pressure plate 3. The two ends of the adsorption pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com