Horizontal spiral feeding device for vertical spiral coke elevator

A vertical screw and horizontal screw technology, applied in the field of horizontal screw feeding devices, can solve the problems of uneven feeding, waste of production capacity, lack of production, etc., and achieve the effect of improving conveying efficiency, avoiding accumulation and saving production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

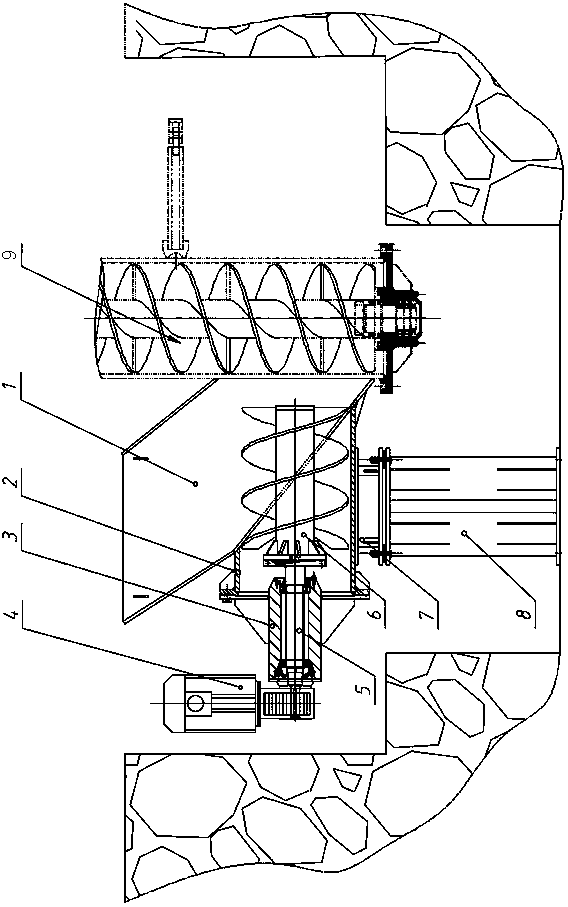

[0013] Referring to the accompanying drawings, the specific implementation is as follows:

[0014] A horizontal screw feeding device for a coke vertical screw elevator, used to assist coke to be transported to the feed inlet at the bottom of the vertical screw elevator 9, including an inclined feeding pipe 1, the feeding pipe 1 passes through five pieces The combined square tube structure welded by steel plates, the bottom of the feeding pipe 1 is connected with the feeding port of the vertical screw elevator 9, so that the material can move obliquely downward along the inner wall of the feeding pipe 1 to the vertical screw elevator 9 There are a plurality of lifting lugs welded on the feeding pipe 1 to facilitate the lifting and installation of the feeding pipe 1.

[0015] The side of the feeding pipe 1 away from the vertical screw elevator 9 is provided with a horizontal cylinder 2, and the side of the vertical spiral elevator 9 is provided with a fixed bracket 8, and a brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com