Textile with temperature regulating function and preparation method thereof

A technology for textiles and temperature regulation, applied in the field of textiles, can solve the problems of poor temperature regulation effect, hard hand feeling of fabrics, poor temperature regulation function, etc., and achieve the effect of improving the temperature inside clothes, low drying temperature and good temperature regulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

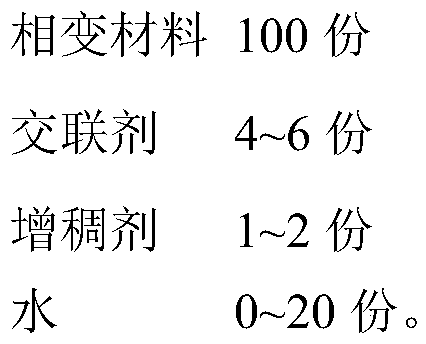

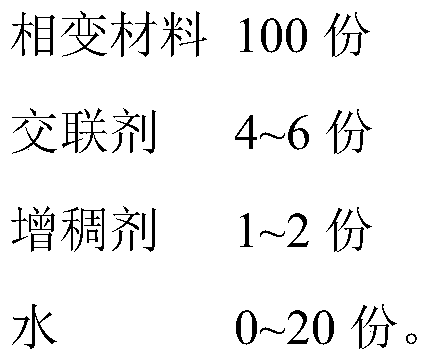

Method used

Image

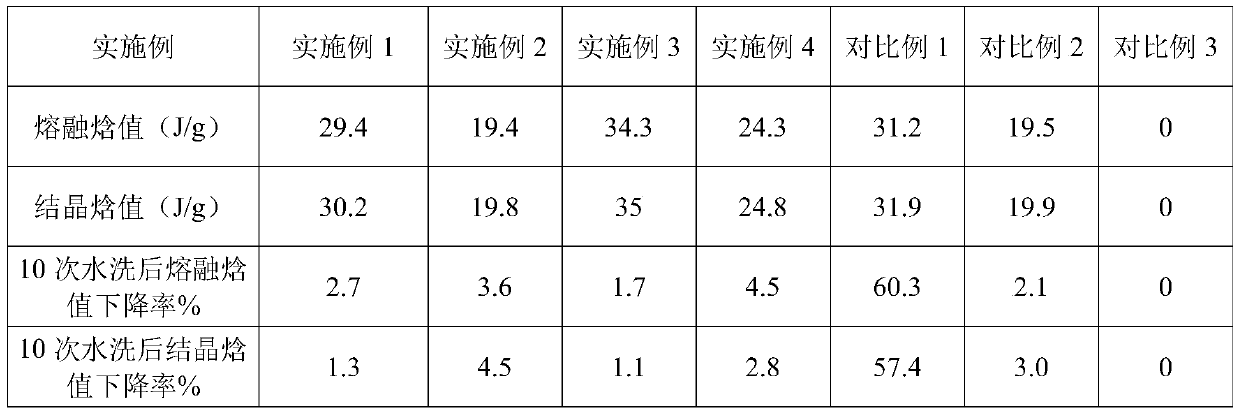

Examples

Embodiment 1

[0033] The material of textile described in the present embodiment is cotton fabric, and grammage is 120g / m 2 .

[0034] Add 100 parts of MPCM30SL80 into the batching barrel, stir for 2 minutes at 1300 rpm, add 1 part of color paste D-501, and stir for 2 minutes. Slowly add 6 parts of cross-linking agent KH-550 and stir for 5 minutes; then add 1 part of thickener DS-J076 and stir while adding until the consistency is 80dPa.s at room temperature to obtain a mixed slurry. Filter the mixed slurry through a 100-mesh filter. Pump the slurry into the printing roller, the mesh of the printing roller is 80 mesh, the printing magnetic rod is 10mm, the printing magnetic force is 55%, the speed is 35m / min, dry at 150°C, and control the dry coating amount to 30g / m 2 .

Embodiment 2

[0036] The material of textile described in this embodiment is polyester fabric, and grammage is 70g / m 2 .

[0037] Put 100 parts of DP-WDF345 into the batching bucket, add 20 parts of tap water, stir for 5 minutes at 1450 rpm, add 1 part of color paste D-501, and stir for 2 minutes. Slowly add 4 parts of crosslinking agent KH-550 and stir for 5 minutes; then add 2 parts of thickener DS-J076 and stir while adding until the consistency is 50dPa.s at room temperature to obtain a mixed slurry. Filter the mixed slurry through a 100-mesh filter. Pump the slurry into the printing roller, the mesh of the printing roller is 100 mesh, the printing magnetic rod is 10mm, the printing magnetic force is 85%, the speed is 35m / min, dry at 140°C, and the dry coating amount is controlled to 20g / m 2 .

Embodiment 3

[0039] The material of textile described in this embodiment is polyester and cotton mixed fabric, and wherein the mass ratio of polyester and cotton is 1:1, and grammage is 110g / m 2 .

[0040] Put 100 parts of DP-WDF345 into the batching bucket, add 10 parts of tap water, stir for 5 minutes at 1500 rpm, add 2 parts of color paste D-501, and stir for 2 minutes. Slowly add 4 parts of crosslinking agent KH-550 and stir for 5 minutes; then add 1 part of thickener DS-J076 and stir while adding until the consistency is 70dPa.s at room temperature to obtain a mixed slurry. Filter the mixed slurry through a 100-mesh filter. Pump the slurry into the printing roller, the mesh of the printing roller is 100 mesh, the printing magnetic rod is 12mm, the printing magnetic force is 65%, the speed is 40m / min, dry at 145°C, and the dry coating amount is controlled at 35g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com