Gas pressure measuring device with high safety factor and using method of gas pressure measuring device

A technology of gas pressure and safety factor, which is applied in the field of gas pressure measurement devices, can solve problems such as lack of auxiliary exhaust protection function, inconvenient installation of drilling pipe head structure, and inability to sample for inspection, so as to ensure the safety of sampling and guarantee The effect of supporting and fixing stability and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing:

[0050] In the picture:

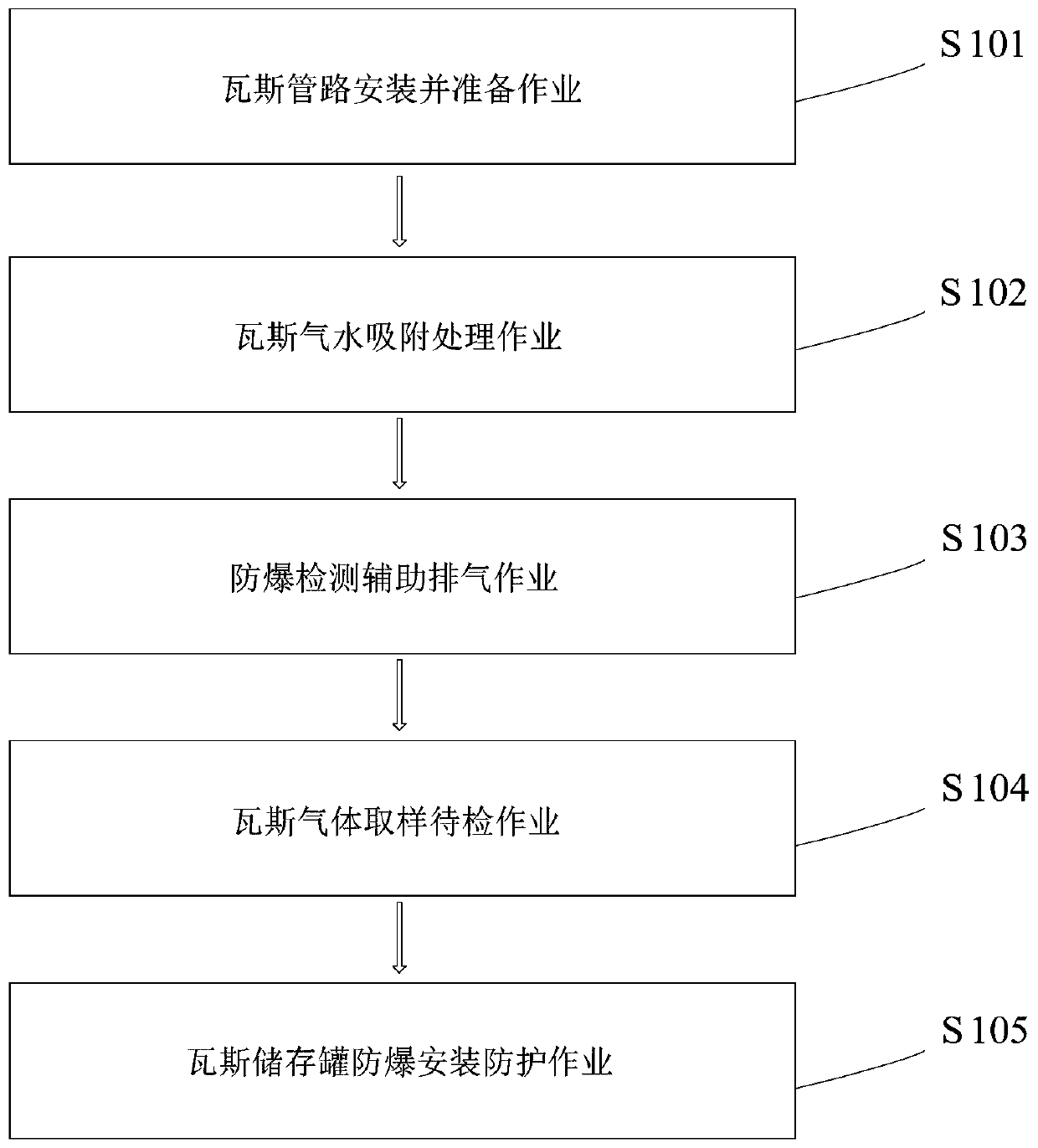

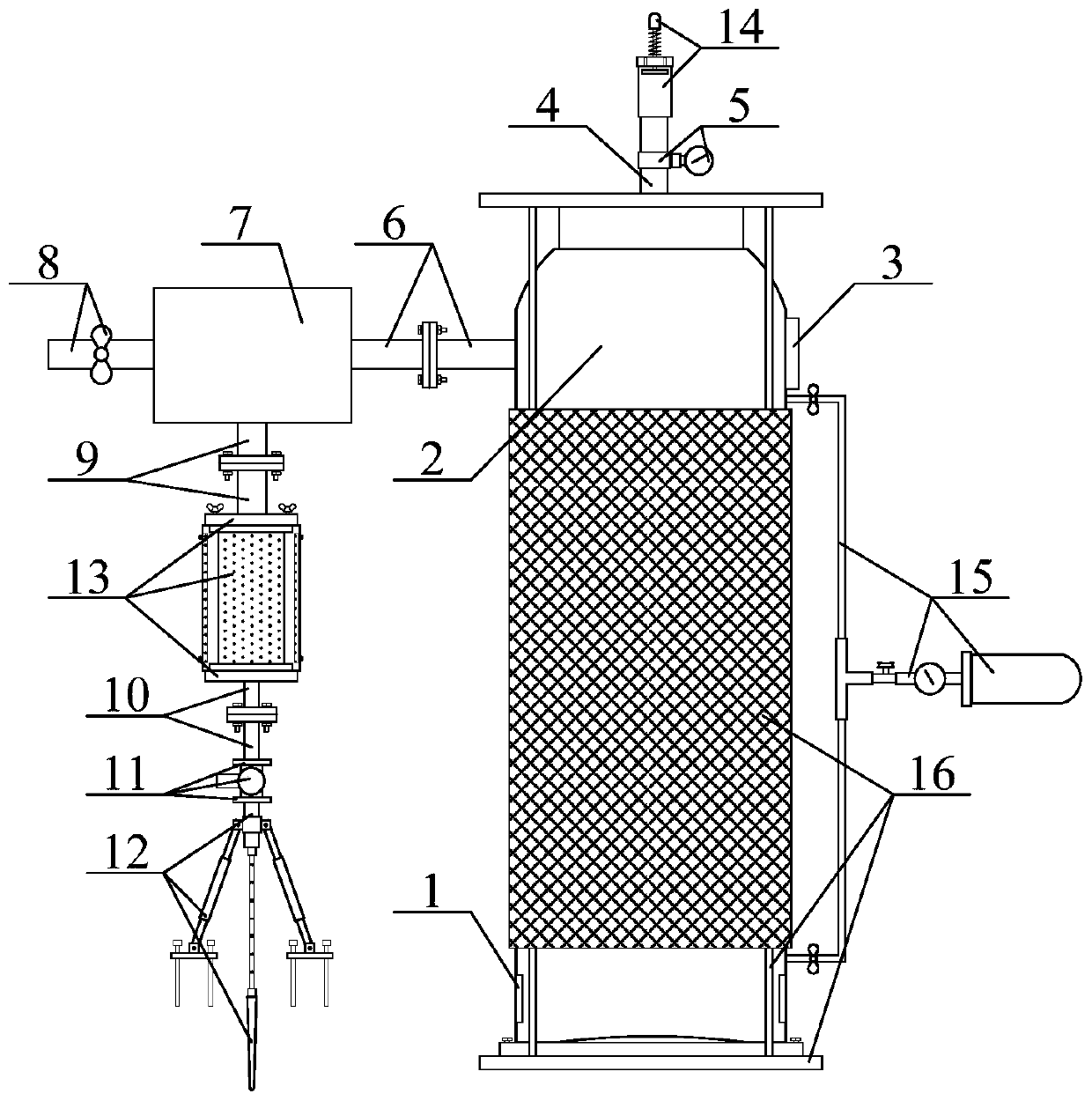

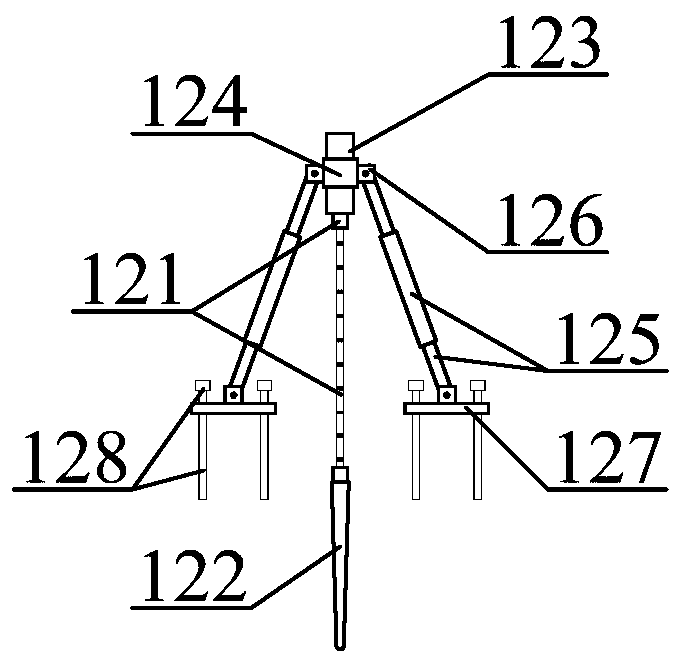

[0051] as attached figure 2 to attach Figure 7 shown

[0052] A gas pressure measurement device with a high safety factor, including a gas pressure measurement sensor 1, a gas storage tank 2, a measurement data display screen 3, an exhaust pipe 4, an air pressure gauge 5, a first flanged connection pipe 6, and a gas-water separation 7, drain pipe with valve 8, second pipe with flange connection 9, third pipe with flange connection 10, suction pump 11, adjustable and fixed installation of gas pipeline support frame 12, impurity adsorption and detachable cleaning core structure 13. An explosion-proof auxiliary gas discharge pipe structure 14, a removable gas sampling bottle structure 15 and an explosion-proof auxiliary protection cylinder structure 16. The gas pressure measurement sensor 1 is screwed under the inside of the gas storage tank 2 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com