Patents

Literature

58results about How to "Guarantee the stability of the support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

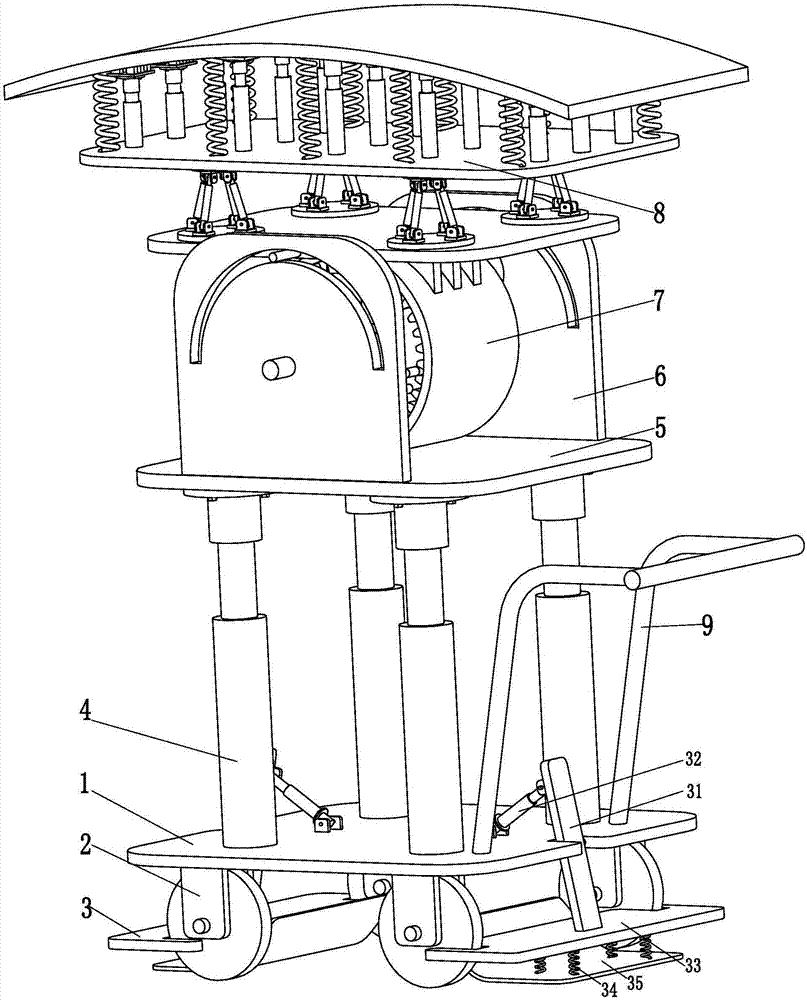

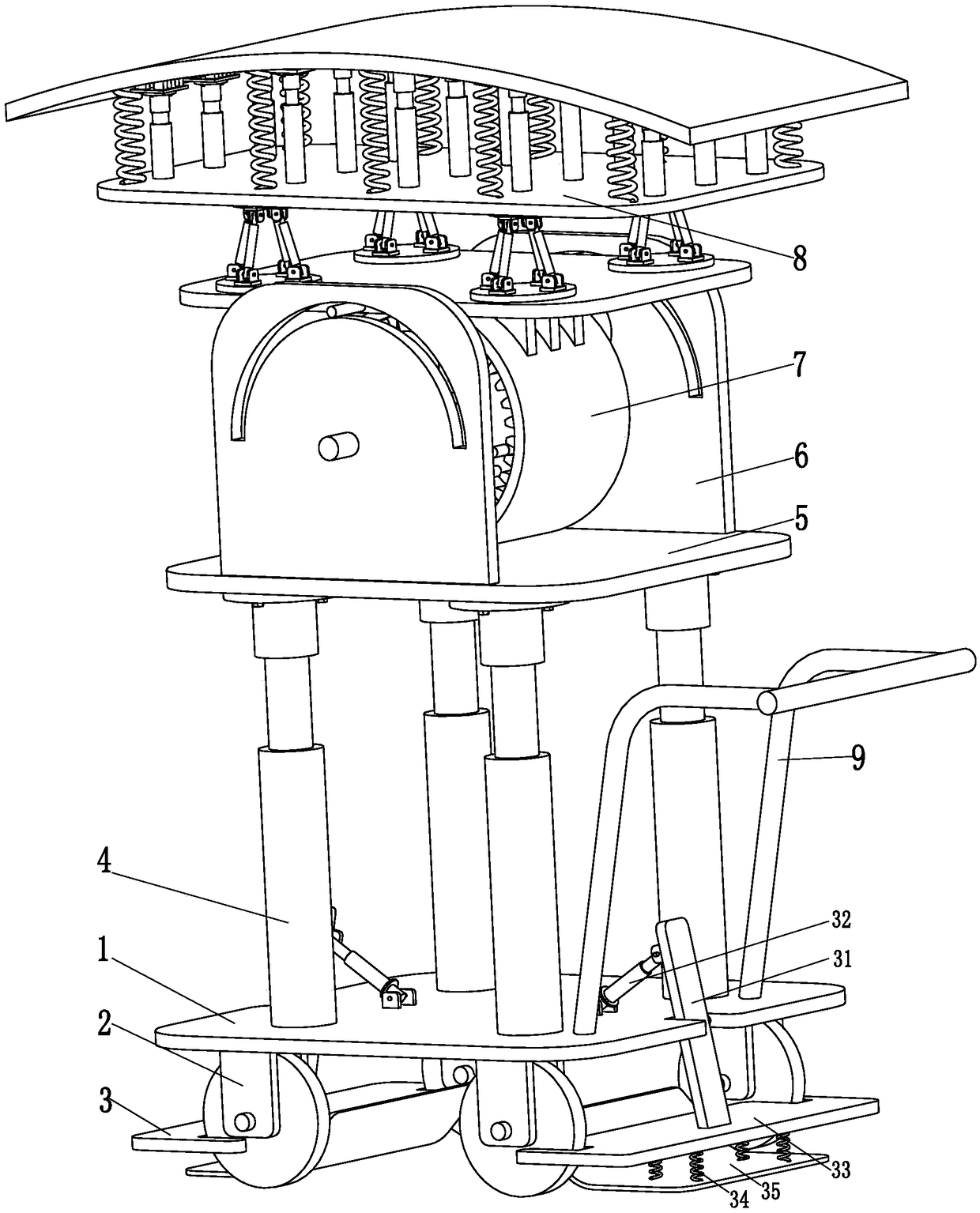

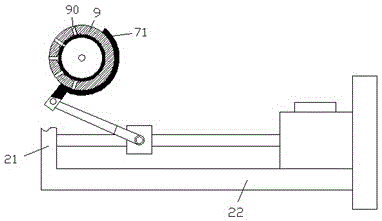

Temporary support device special for tunnels and bridges

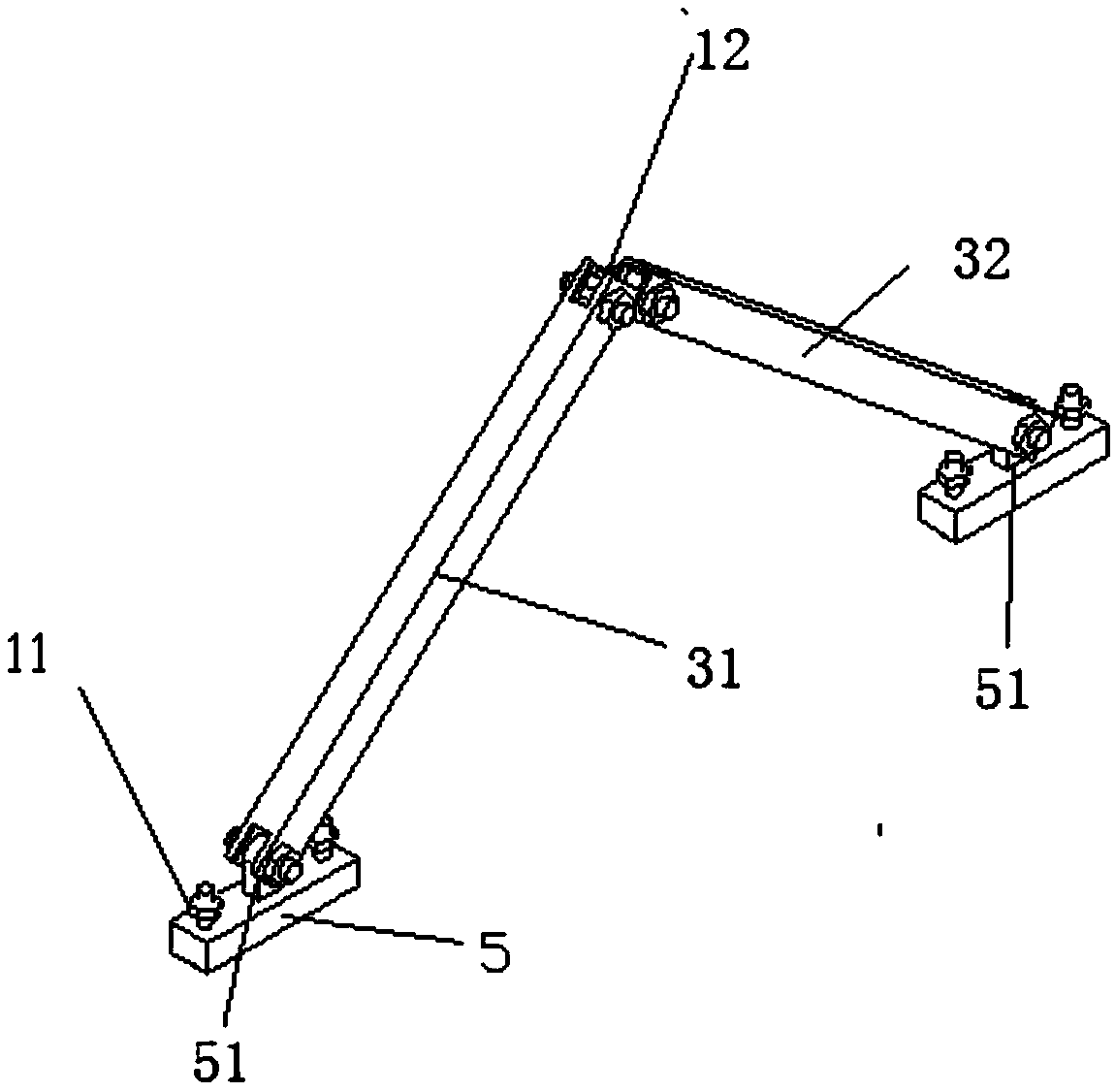

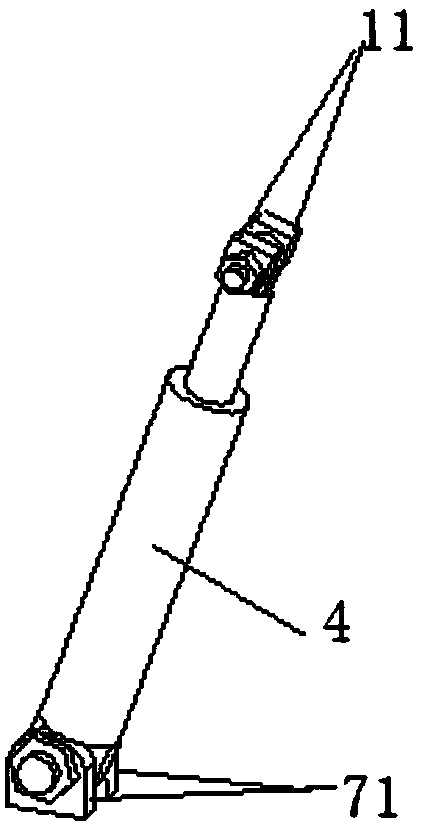

ActiveCN107059634AImprove stabilityReduce labor intensityBridge erection/assemblyMine roof supportsHydraulic cylinderBaseboard

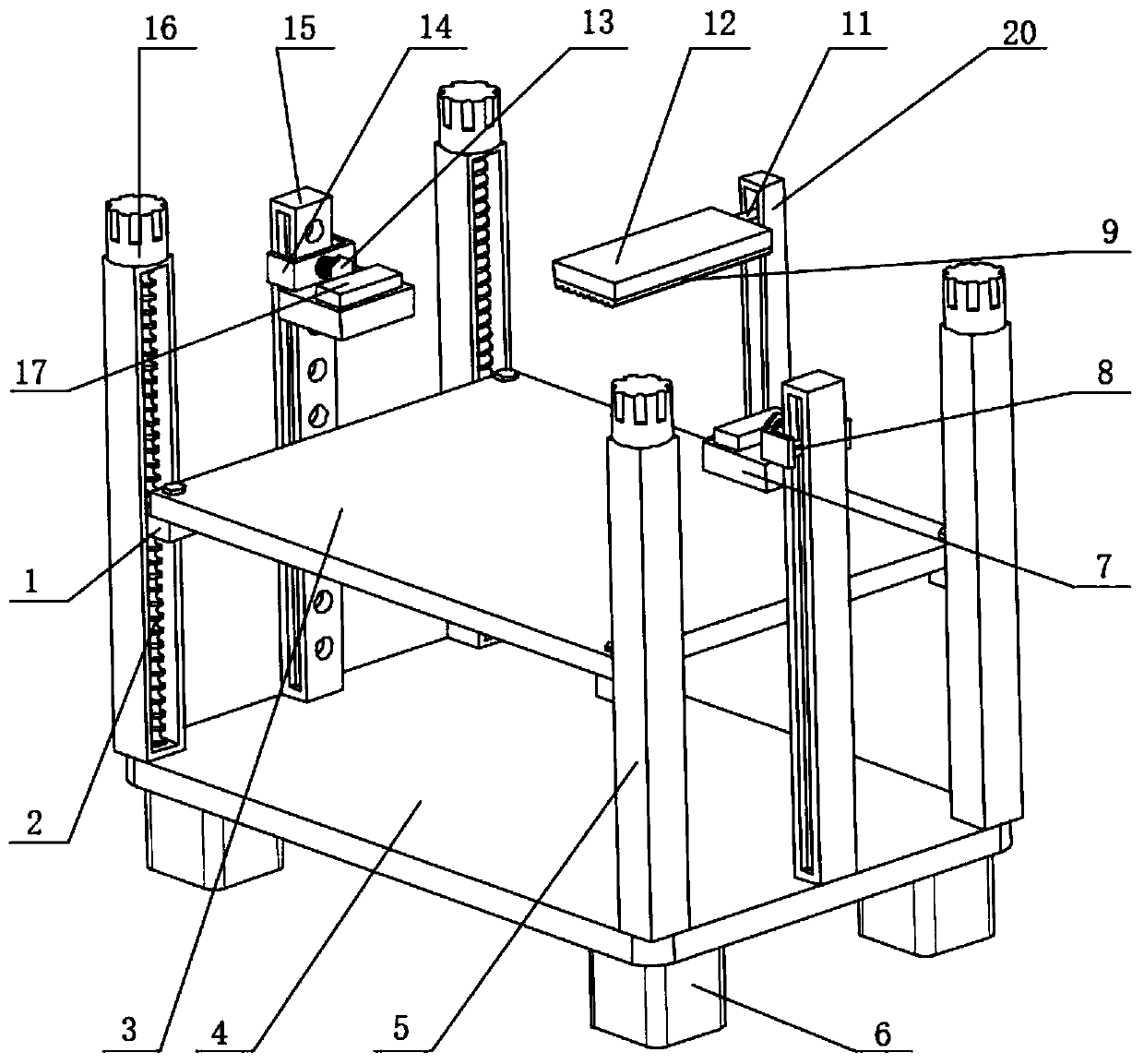

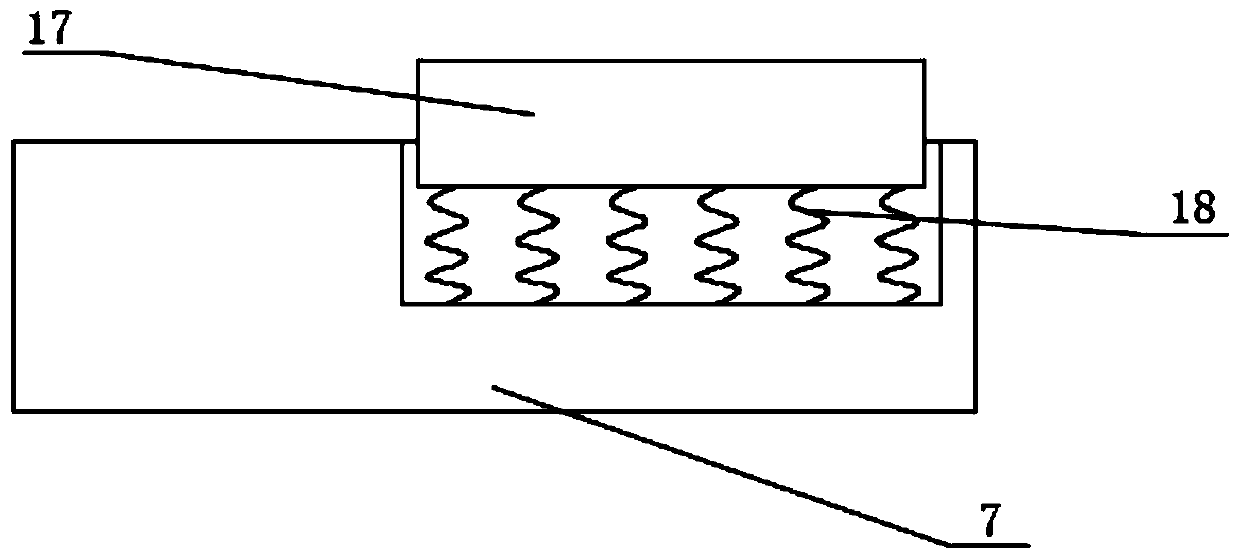

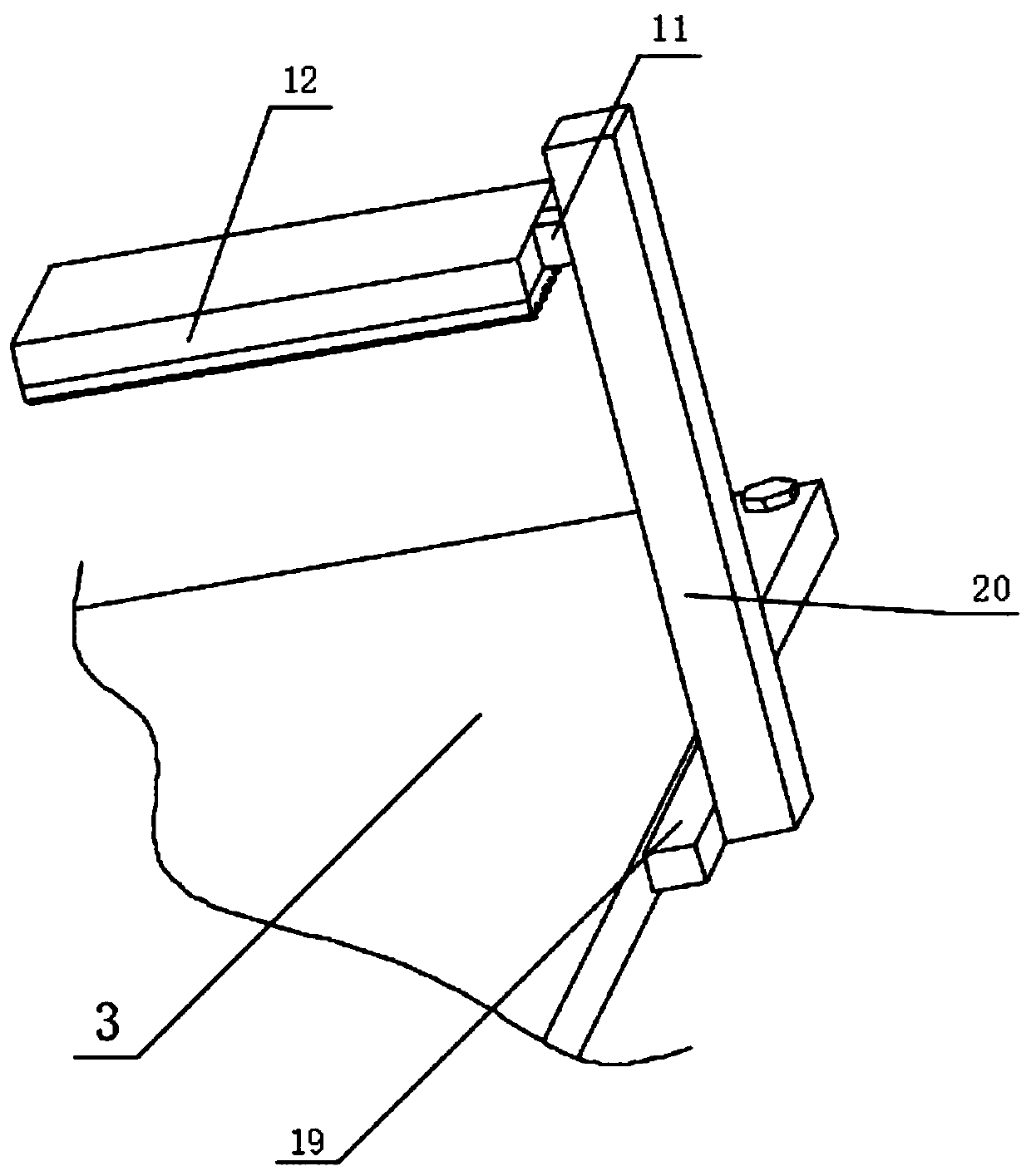

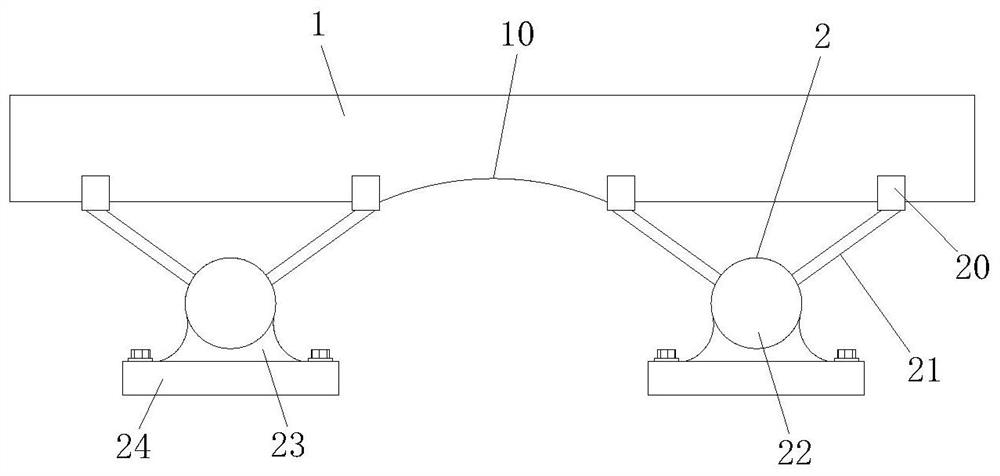

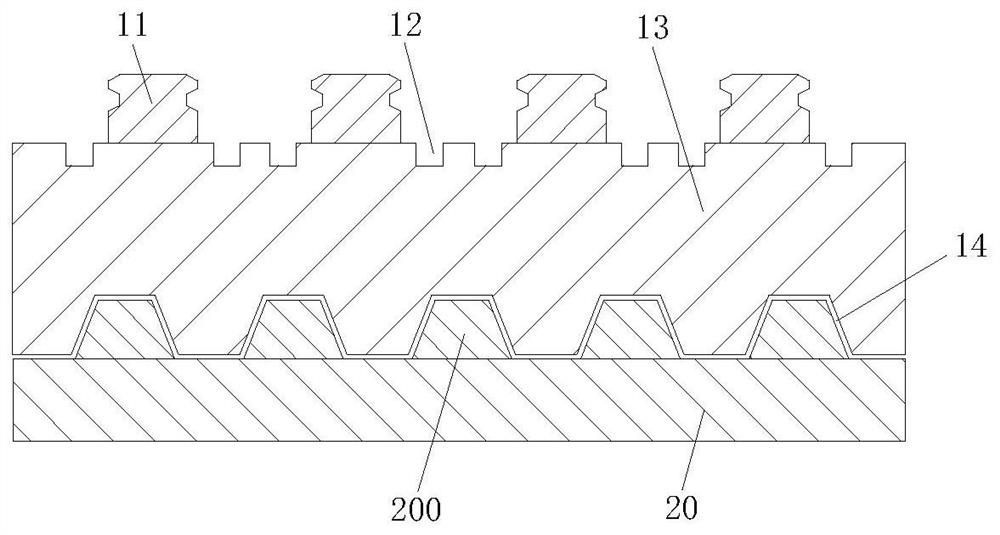

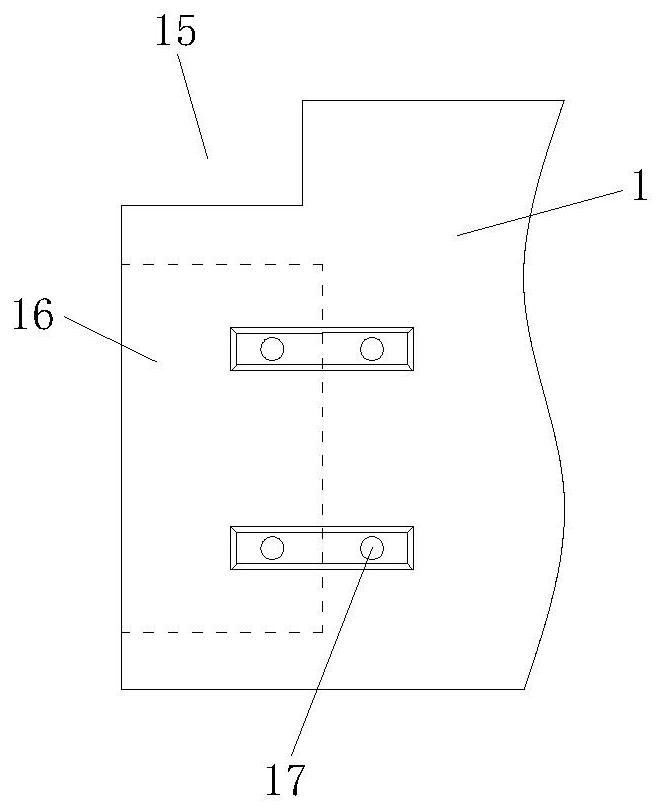

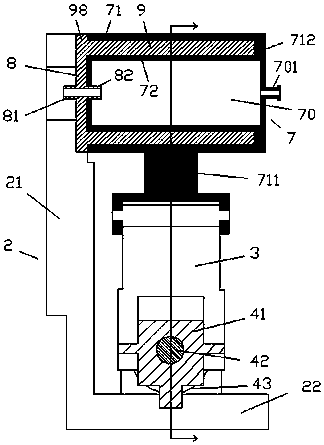

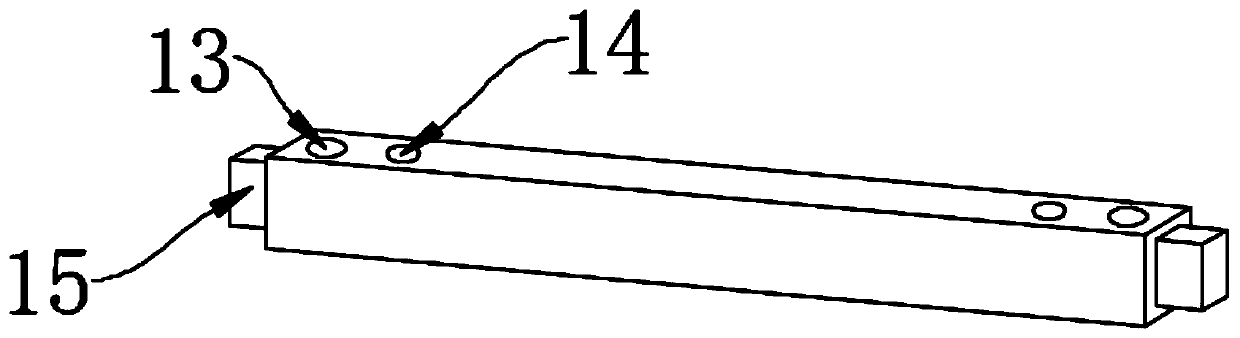

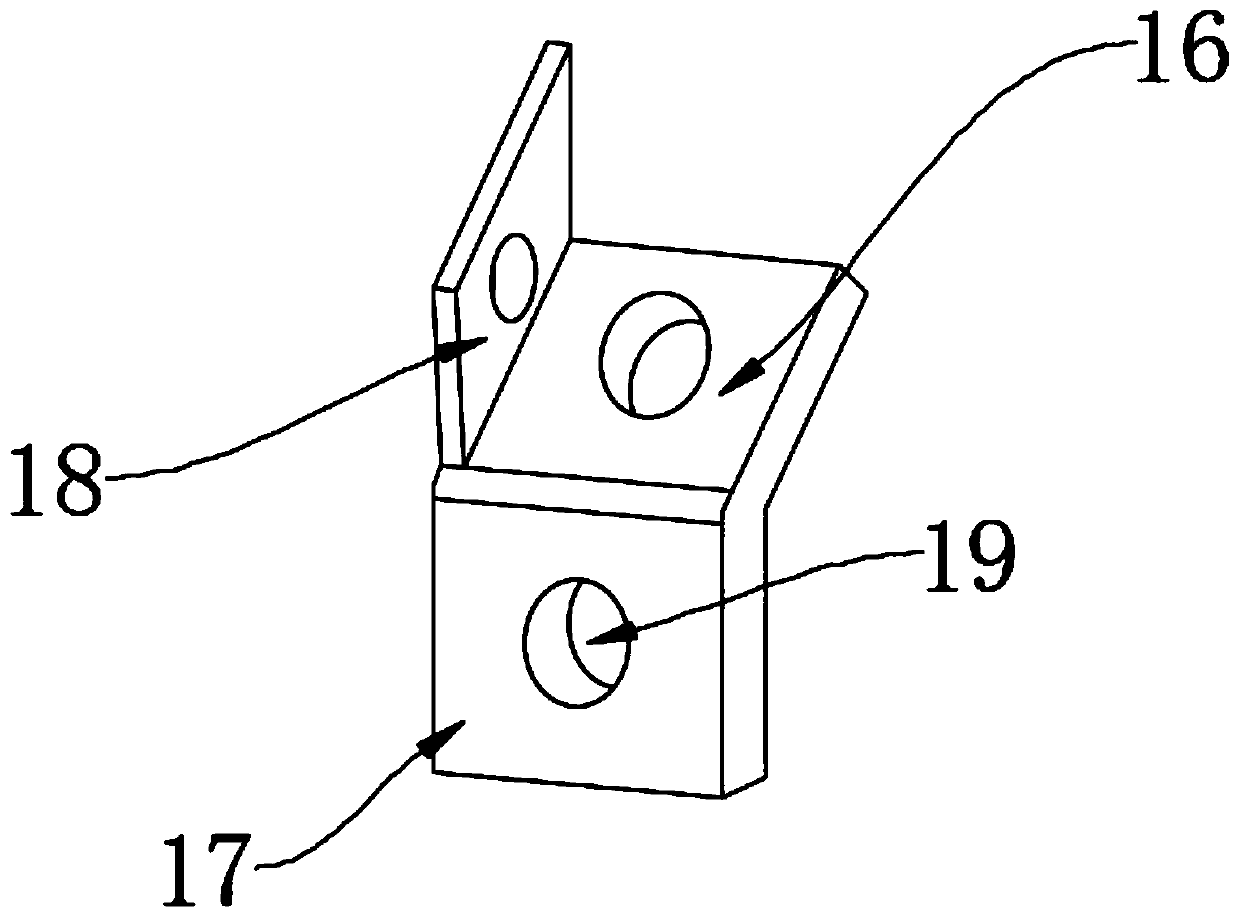

The invention relates to a temporary support device special for tunnels and bridges The temporary support device special for the tunnel and the bridge comprises a baseboard, the front end and the back end of the baseboard is symmetrically provided with two limit fixed devices, a rise and fall hydraulic cylinder is symmetrically arranged on the upper end of the baseboard, the top of the rise and fall hydraulic cylinder is fixed on a batter board through flange, two control apparatus are arranged on the upper end of the batter board, a regulation column is arranged between the two control apparatus. A support device is arranged on the upper end of the regulation column, the fixed devices, the control apparatus, and the regulation column are used cooperatively to be finished the tunnel and bridge temporary support technology. The temporary support device special for tunnels and bridges solves the difficult problems that the existing tunnels and bridges construction during the temporary support constructing, the material like concrete and steel frame are processed into the temporary support by workers, the cost time is long, the progress of works is influenced, the road works are constructed correspondingly aim at different structures, the labour intensity is high, the operation is complex, the resource is wasted, and the work efficiency is low. The temporary support automation adjusting function is realized.

Owner:高军

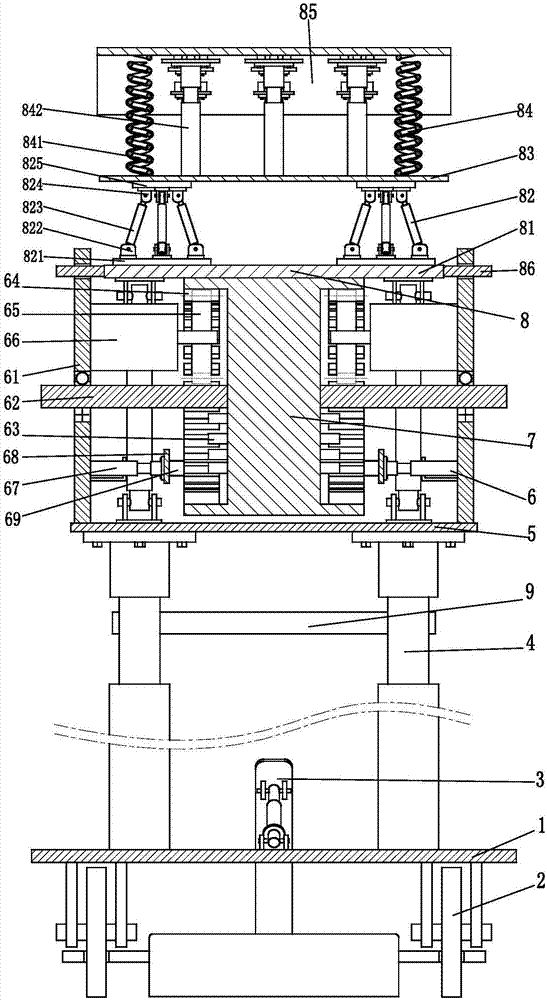

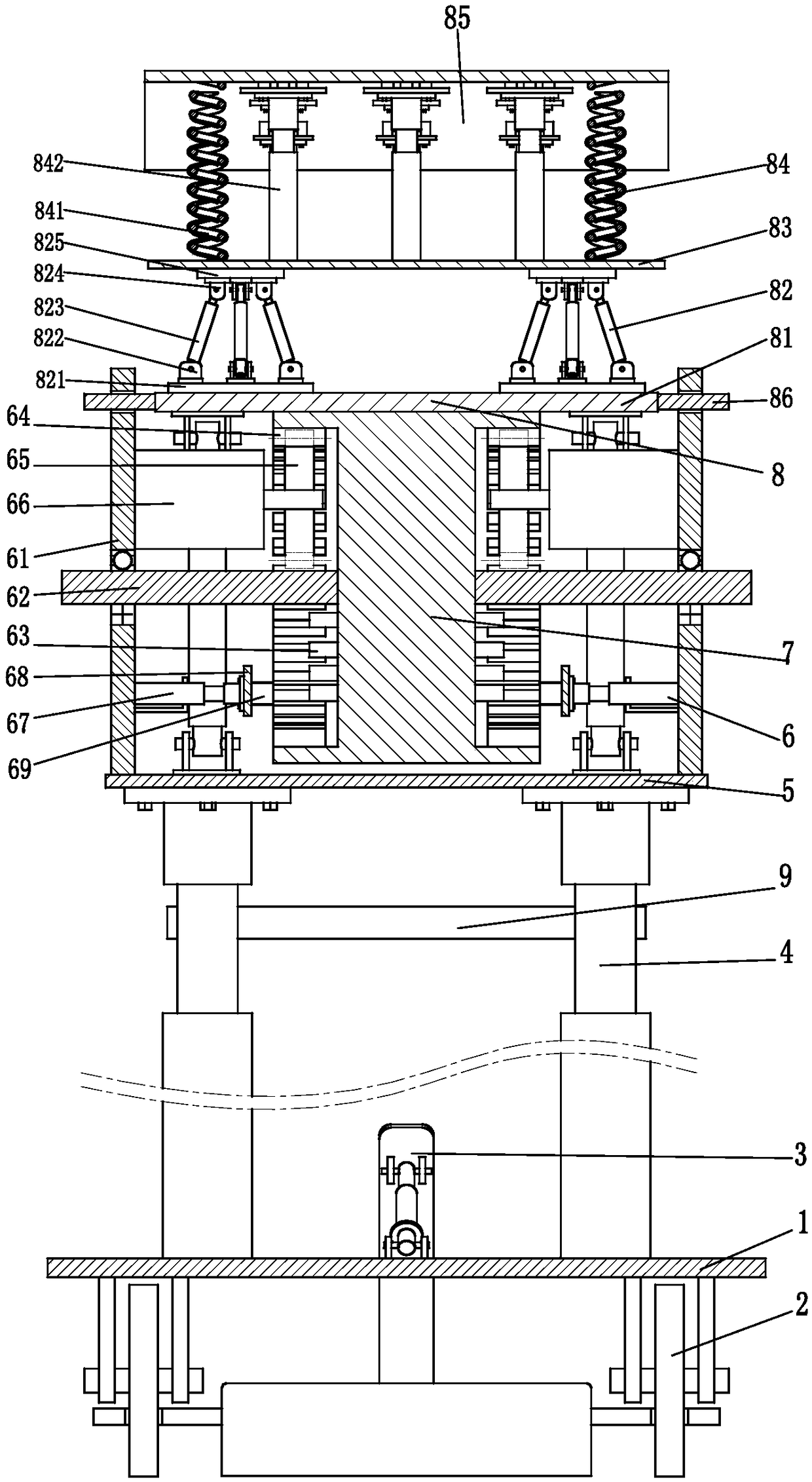

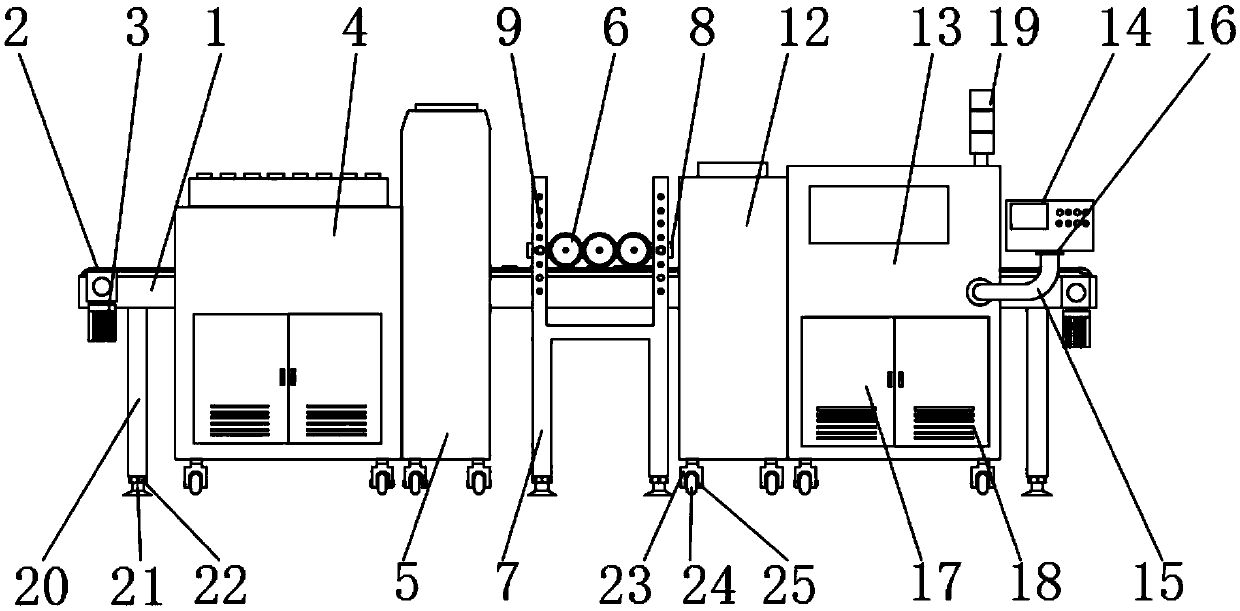

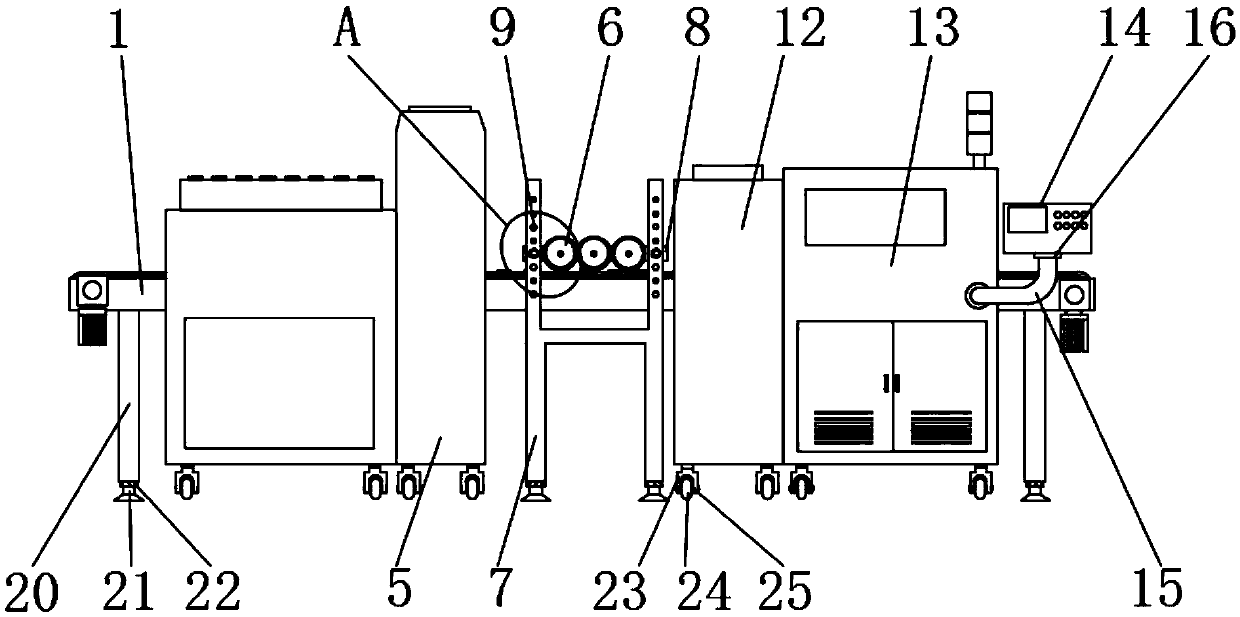

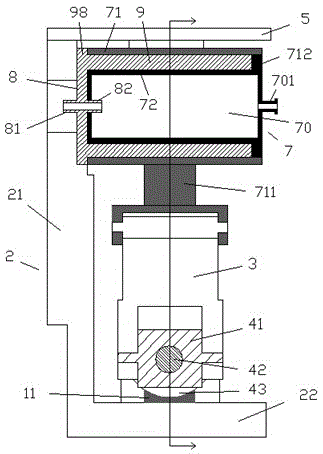

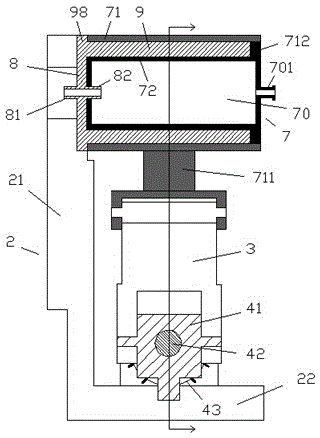

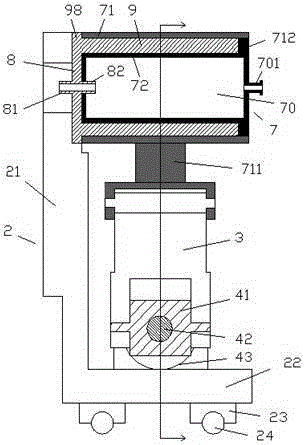

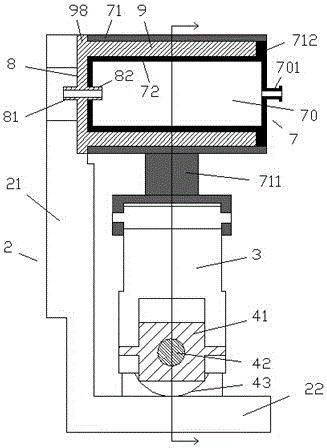

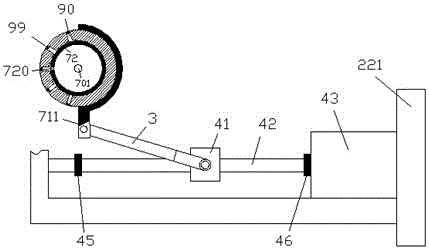

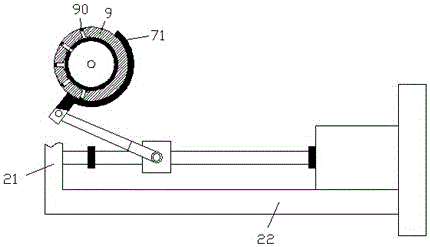

Tunnel bridge construction temporary support equipment

ActiveCN109356632ARealize the function of automatic adjustment of temporary supportEasy to operateBridge erection/assemblyMine roof supportsHydraulic cylinderArchitectural engineering

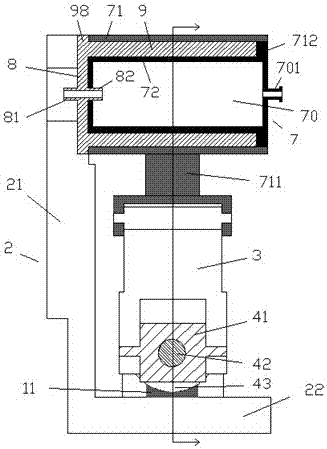

The invention relates to tunnel bridge construction temporary support equipment comprising a bottom plate. Two fixing devices capable of realizing limiting are symmetrically mounted at the front end and the rear end of the bottom plate, lifting hydraulic cylinders are symmetrically mounted at the upper end of the bottom plate, and the top ends of the lifting hydraulic cylinders are mounted on a positioning plate through flanges; two adjusting devices are symmetrically mounted at the upper end of the positioning plate, an adjusting column is mounted between the two adjusting devices, and a supporting device is mounted at the upper end of the adjusting column; and a technology for tunnel bridge temporary support is completed through mutual cooperation of the fixing devices, the adjusting devices, the adjusting column and the supporting device. According to the tunnel bridge construction temporary support equipment, the difficult problems that in the existing tunnel bridge construction temporary support building process, materials such as concrete and steel frames need to be manually processed into temporary supports, the consumed time is long, the project progress is affected, the corresponding temporary supports need to be constructed according to construction faces of different structures, the labor intensity is high, operation is complex, sources are wasted, and the working efficiency is low can be solved, and the function of automatically adjusting the temporary supports can be achieved.

Owner:江苏锡沂钢模有限公司

Construction equipment supporting platform for building construction

InactiveCN110905179AEasy to moveConvenience to workBuilding scaffoldsArchitectural engineeringScrew thread

The invention discloses a construction equipment supporting platform for building construction, relates to the technical field of building construction, and aims to solve the problem that the height of an existing supporting platform is certain, so that the height of the supporting platform cannot be adjusted. The construction equipment supporting platform specifically comprises a base and four rubber seats, wherein each of the two sides and the two ends of the outer wall of the top of the base is provided with a supporting column, each of the outer walls of the opposite one sides of the supporting columns is provided with a rectangular groove, the inner walls of the tops and the bottoms of each rectangular groove are rotatably connected with the same corresponding screw rod, the outer walls of the circumferences of the screw rods are rotationally connected with first sliding blocks through threads correspondingly, the outer walls of the tops of the supporting columns are provided withmotors correspondingly, and motor output shafts are fixedly connected with the outer walls of the top of the screw rods through bolts correspondingly. According to the supporting platform, by arranging the motors, the supporting columns, the screw rods and the sliding blocks, construction equipment on a supporting plate can be driven to rise, the construction equipment can be conveniently moved to a working place, and the subsequent work is facilitated.

Owner:刘岩岩

Hydraulic vertical rotary experimental platform for fatigue test of tensile anchor plate

ActiveCN109374396AImprove structural strengthSimple structureStrength propertiesEngineeringFatigue testing

Owner:WUHAN UNIV OF TECH

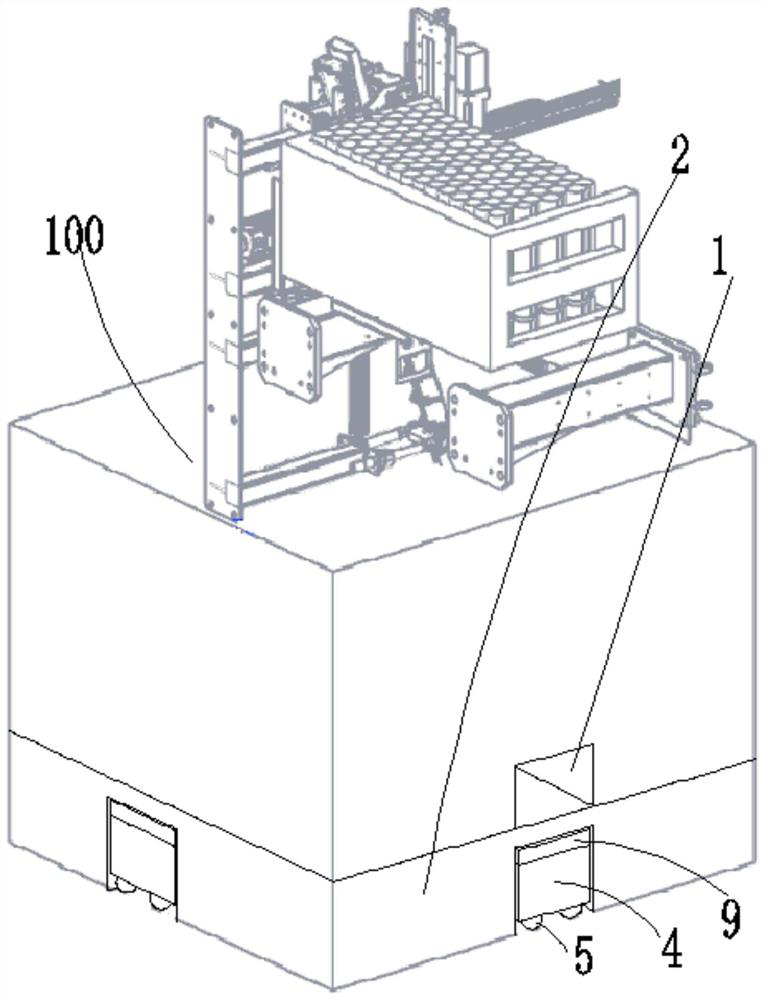

Intelligent production device based on furniture parts

InactiveCN109514266AStable supportEasy to moveOther manufacturing equipments/toolsPunchingFixed frame

The invention relates to the technical field of production equipment and discloses an intelligent production device based on furniture parts. The intelligent production device comprises a device body.A punching chamber is arranged on the outer surface of the upper end of the device body. Punch rods are arranged on the inner side of the punching chamber. The lower ends of the punch rods are provided with springs, and limiting seats are arranged at the lower ends of the punch rods. Punches are fixedly installed at the lower ends of the limiting seats. Fixed frames are arranged on the outer surface of the lower end of the device body. Movable frames are arranged on the outer surfaces of the lower ends of the fixed frames, and the outer surfaces of the front ends of the movable frames are provided with sleeves. A supporting frame is arranged on the side, away from the fixed frames, of the punching chamber, polishing rotating rollers are arranged on one side of the supporting frame, and acontrol box is arranged on one side of the supporting frame. The intelligent production device based on furniture parts is convenient to operate, the device body can move conveniently under the cooperation of the fixed frames and wheels, the punch moving smoothness can be improved, and the height of the polishing rotating rollers can be adjusted conveniently.

Owner:刘道灵

Gas pressure measuring device with high safety factor and using method of gas pressure measuring device

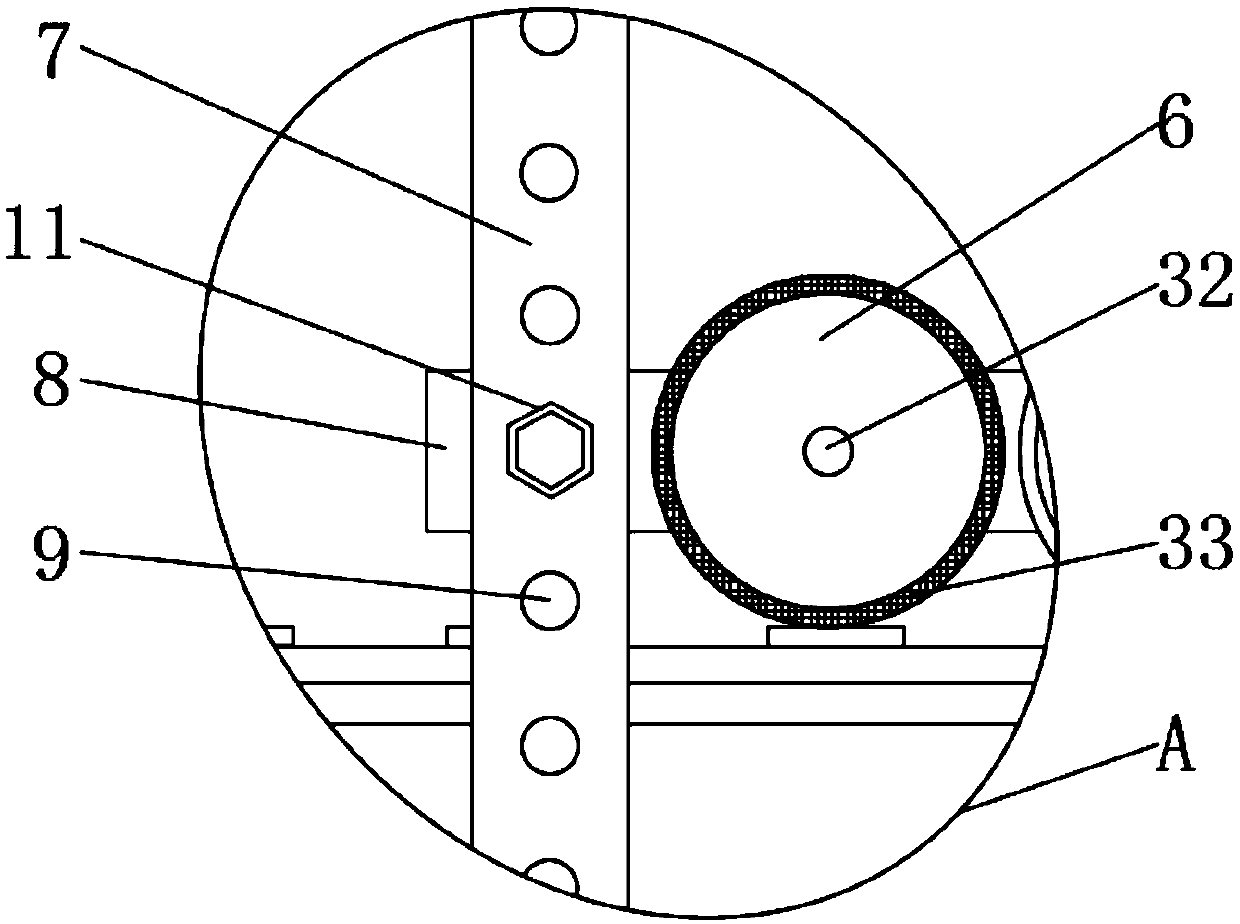

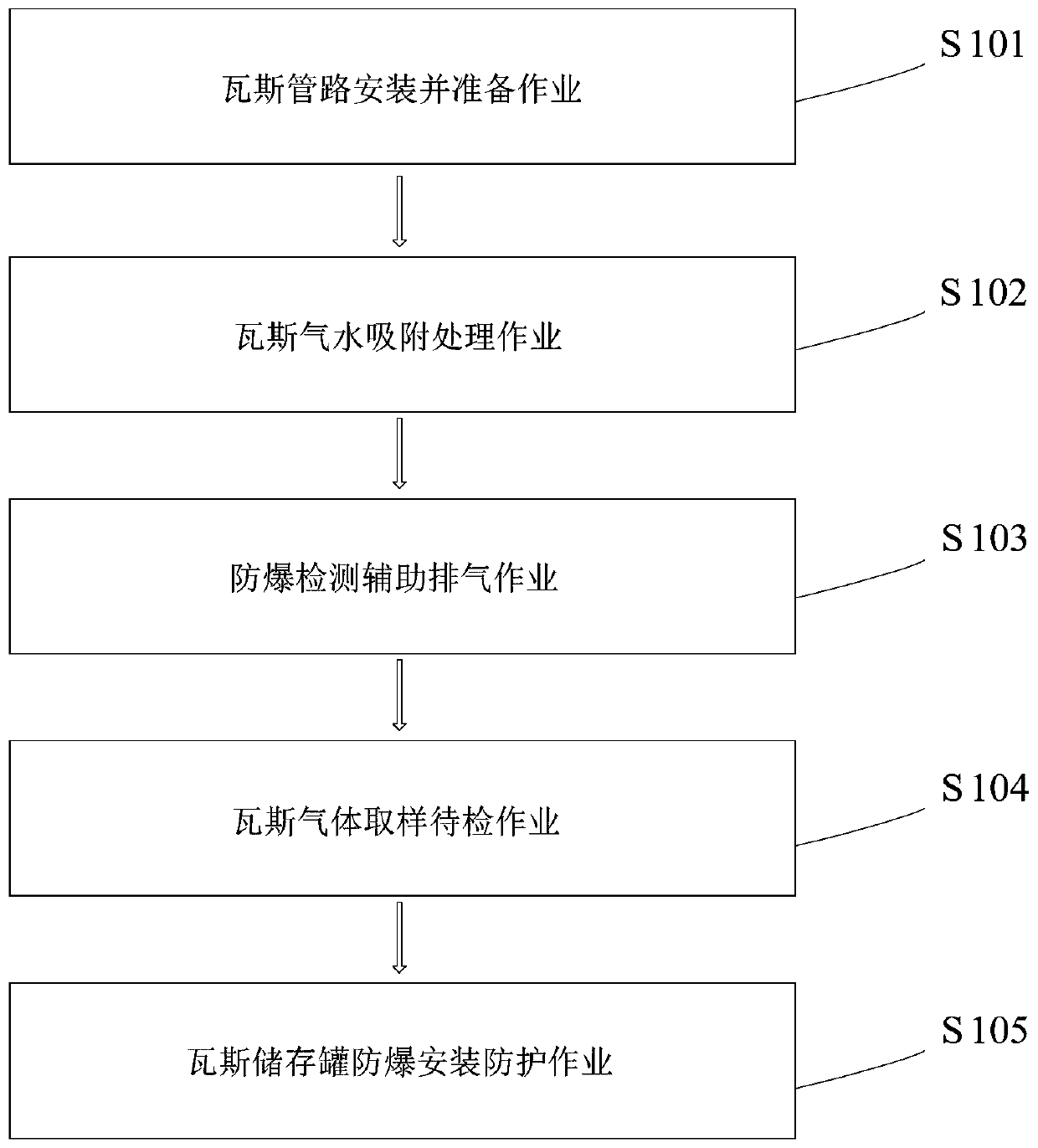

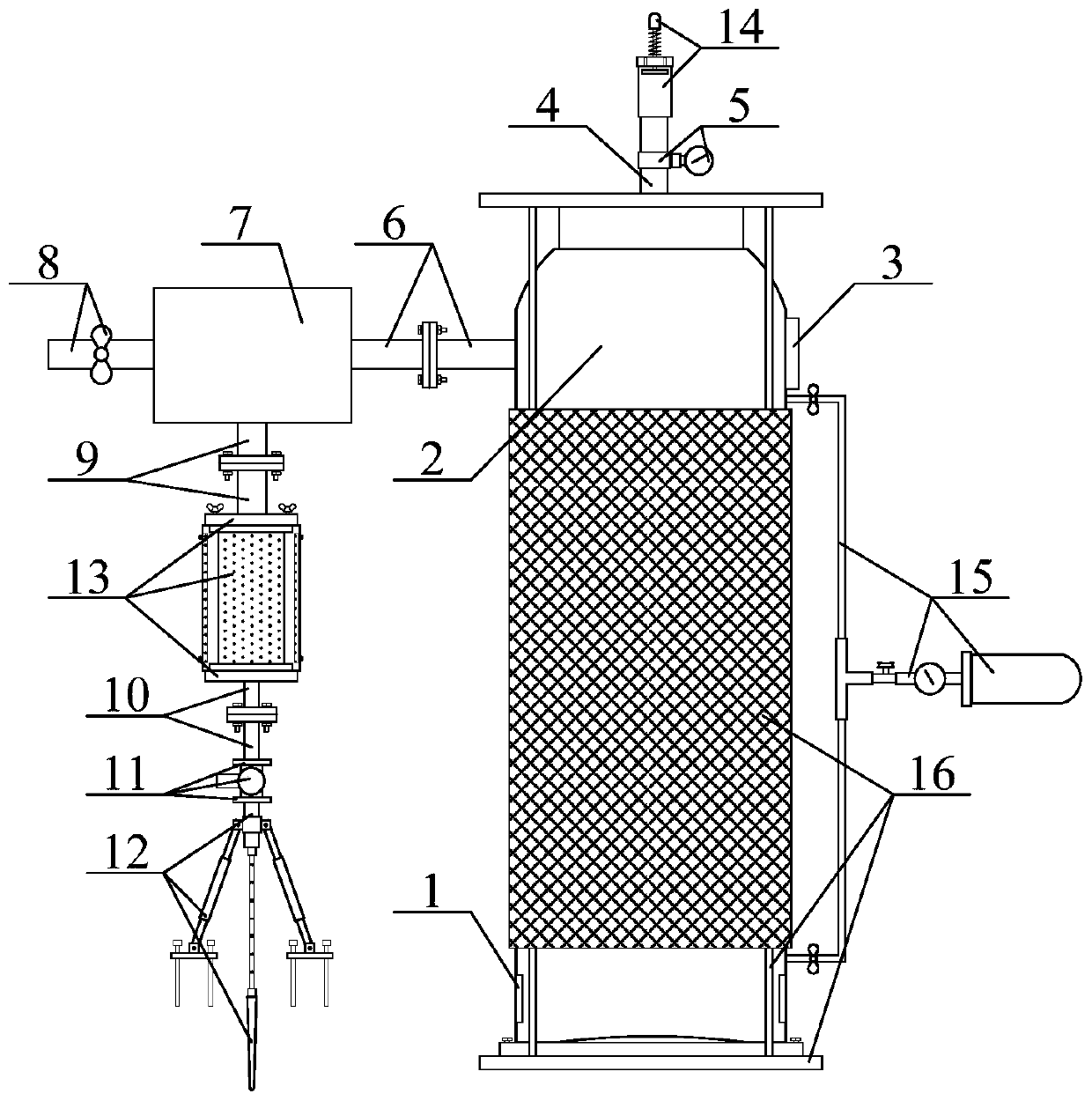

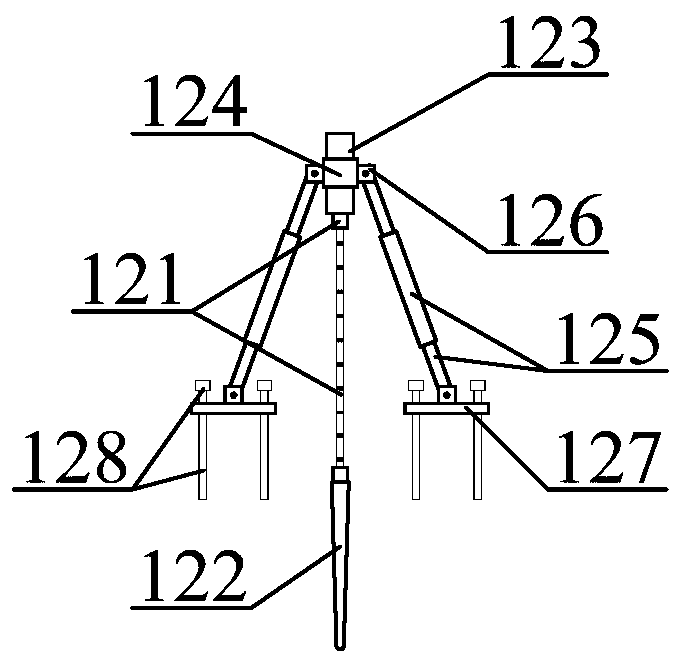

InactiveCN110566185AImprove support stabilityGood for adsorption and retentionSurveyFluid removalData displayProduct gas

The invention provides a gas pressure measuring device with high safety factor. The gas pressure measuring device comprises a gas pressure measuring sensor, a gas storage tank, a measuring data display screen, an exhaust pipe, a gas-pressure meter, a first flanged connecting pipeline, a gas-water separator, a valved drainage pipe, a second flanged connecting pipeline, a third flanged connecting pipeline, a suction pump, an adjustable fixed installation gas pipeline supporting frame, a detachable clearing core structure capable of adsorbing impurities, an explosion-proof auxiliary gas dischargestructure, a gas sampling to-be-inspected bottle structure capable of taking and putting and an explosion-proof auxiliary protective barrel structure. According to the gas pressure measuring device,a metal soft guide pipe, a cone-shaped suction pipe and an eduction pipe are arranged, self bending is advantageously adjusted according to the bending degree of a drilled hole, gas water can be conveniently sucked out, and the smooth progress of the gas pressure measurement work is ensured.

Owner:NORTH CHINA INST OF SCI & TECH

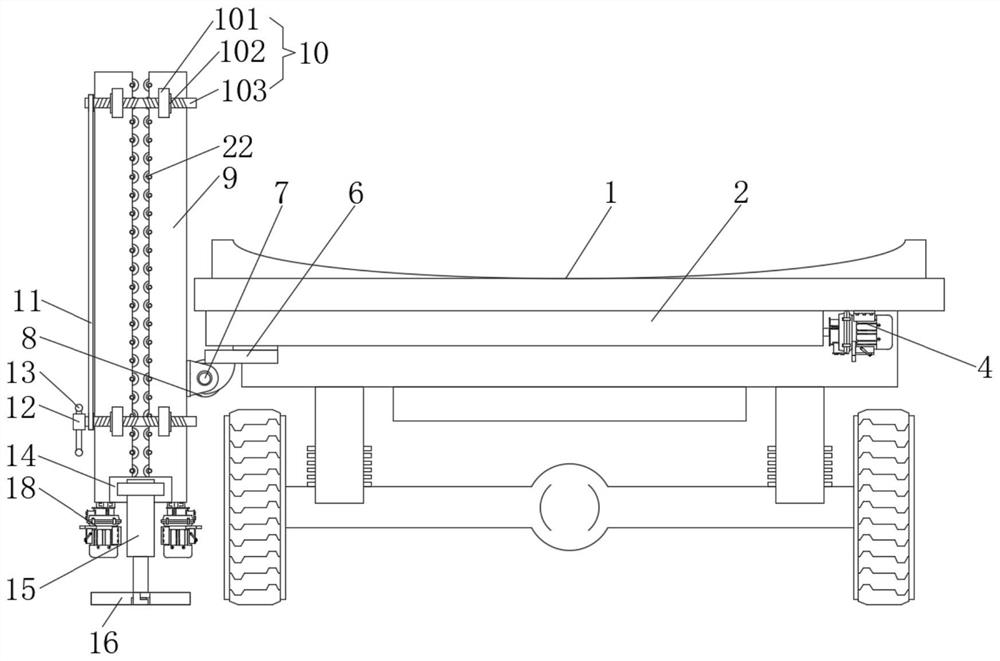

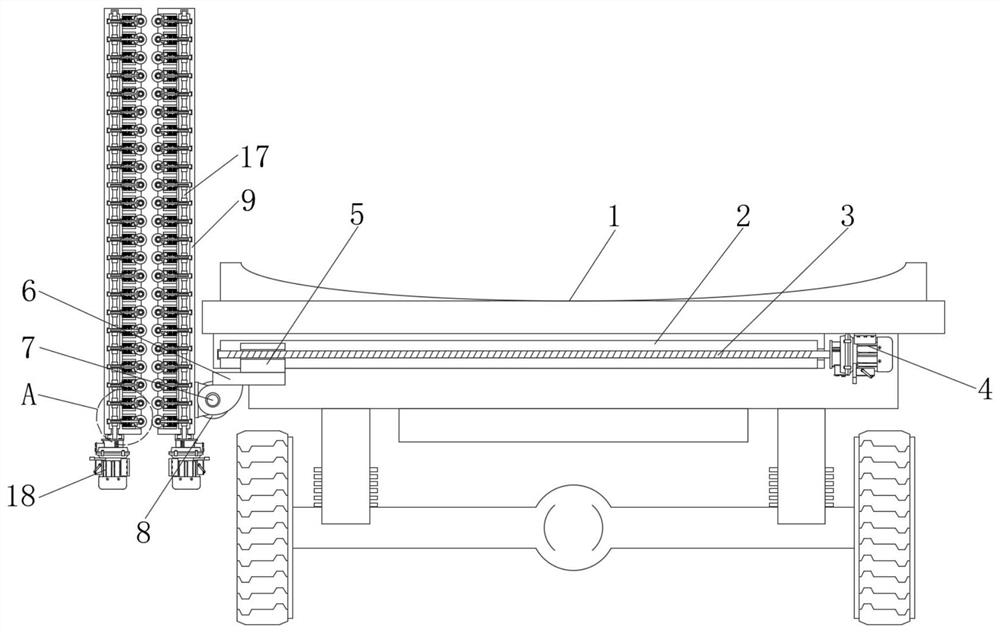

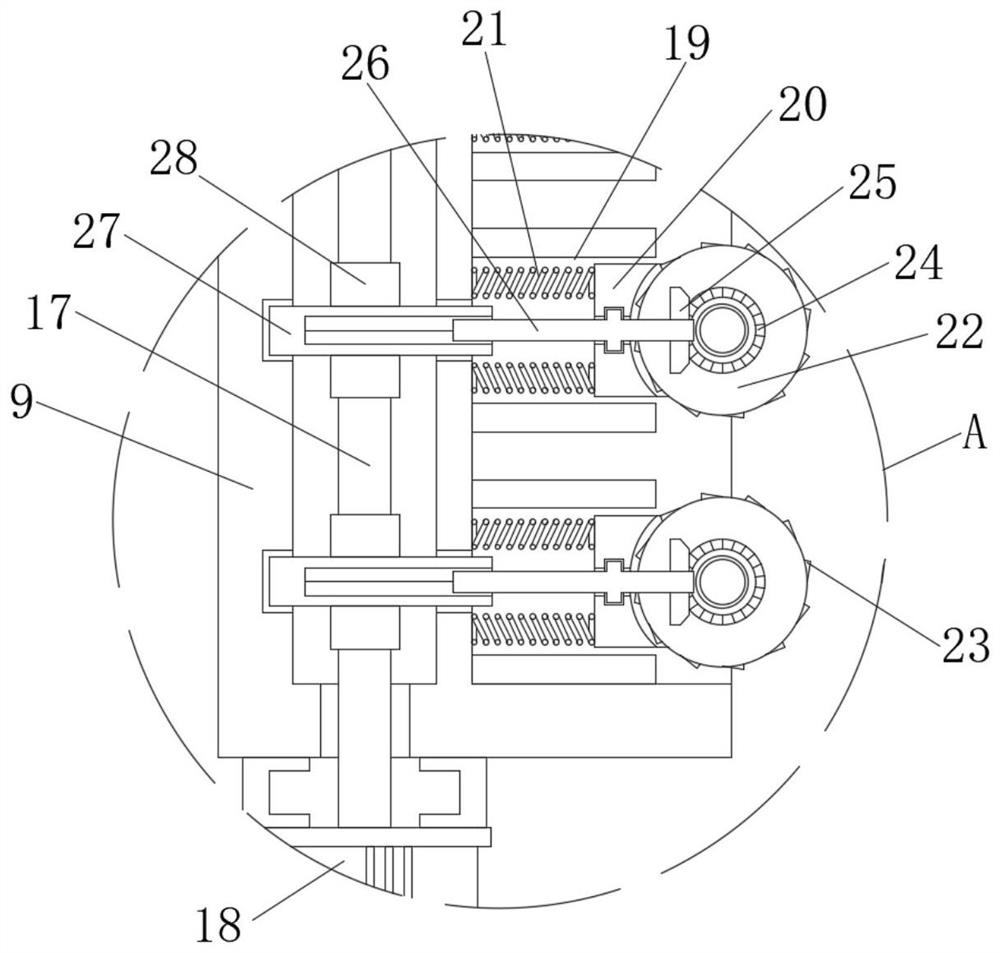

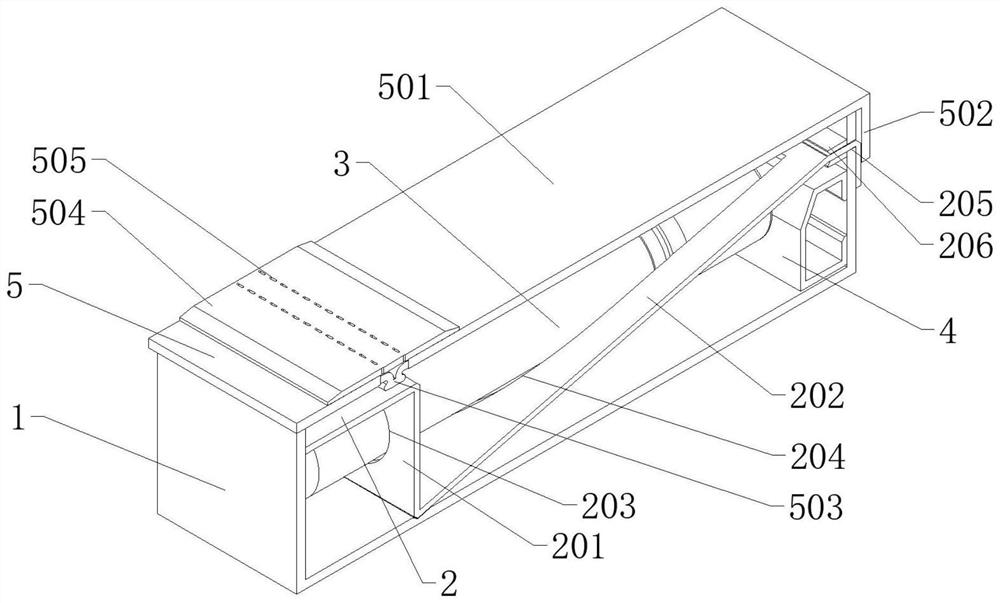

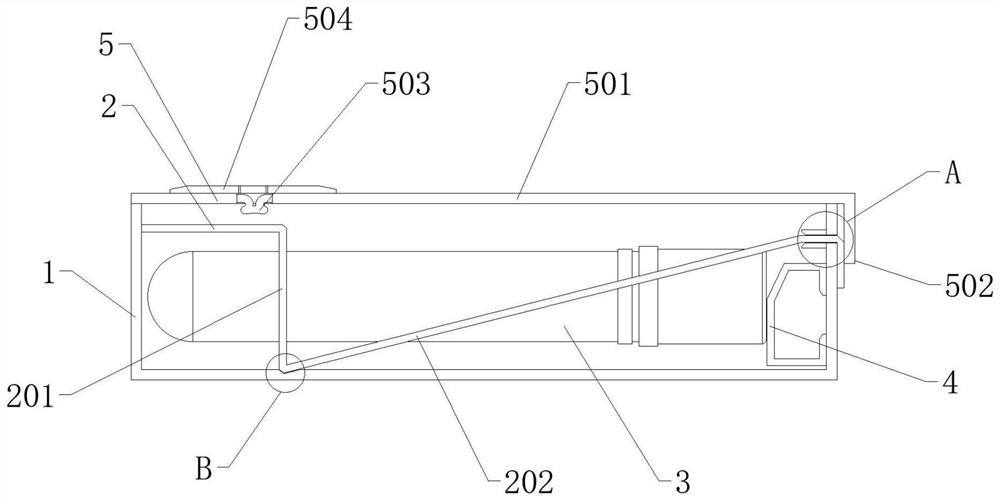

Auxiliary lifting supporting leg for steel pipe transport vehicle based on constructional engineering instruments

InactiveCN111824081AEasy to transportReduce labor burdenVehicle fittings for lifting and manoeuvringCarriageSteel tube

The invention relates to the technical field of auxiliary equipment for constructional engineering steel pipe instrument transportation, and particularly relates to an auxiliary lifting supporting legfor a steel pipe transport vehicle based on constructional engineering instruments. The auxiliary lifting supporting leg comprises a carriage main body, a first servo motor, a second servo motor, a belt pulley transmission mechanism, a hydraulic telescopic rod and a third servo motor, a sliding rail is fixedly installed at the bottom of the carriage body, a first screw rod is inserted into the sliding rail in a penetrating mode, one end of the first screw rod is fixedly connected with the first servo motor, and the outer side of the first screw rod is sleeved with a sliding block. Rotating wheels are symmetrically arranged in the two sets of lifting outer frames. Through the rotation of the rotating wheels and the elastic support of springs, a steel pipe can be shifted upwards by the rotating wheels and continuously conveyed upwards, so that the steel pipe is convenient to convey, the manual carrying of a worker is not needed, the labor burden of the worker is effectively reduced, andthe working safety in the lifting process is conveniently guaranteed.

Owner:李梁稳

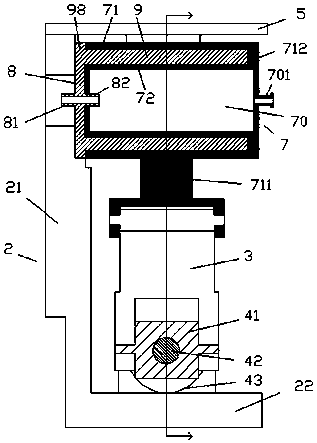

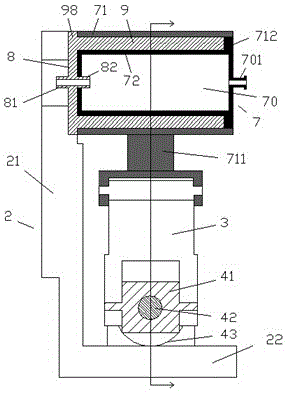

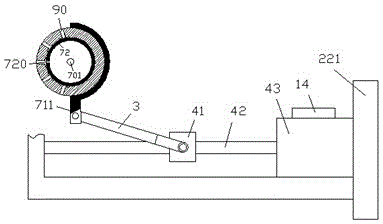

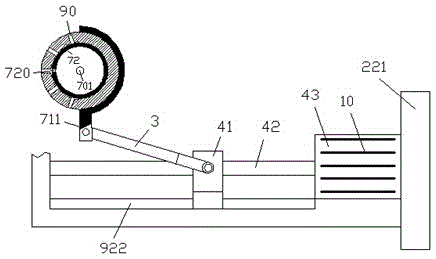

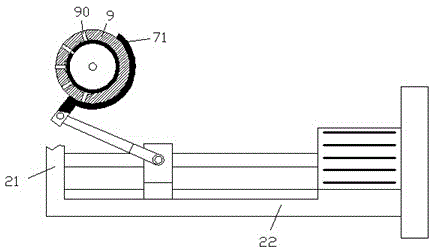

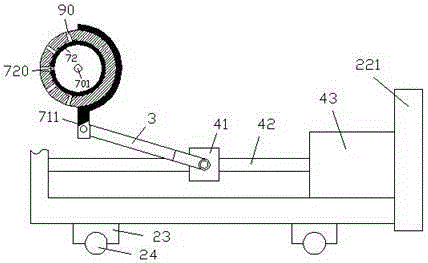

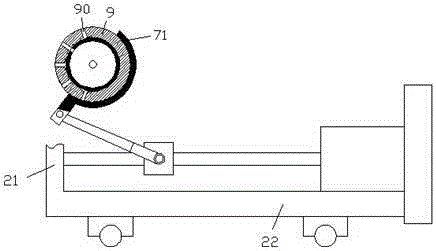

Dust-proof shock-absorbing type air conditioner condensate water drain device

ActiveCN105115141AReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusMarine engineeringWater jet

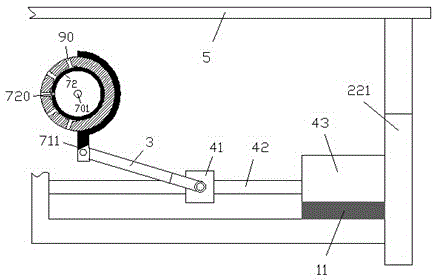

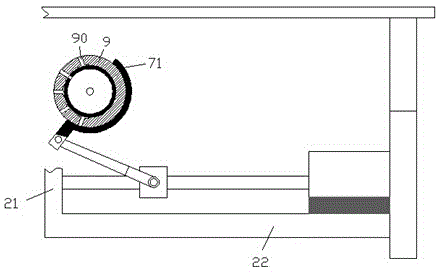

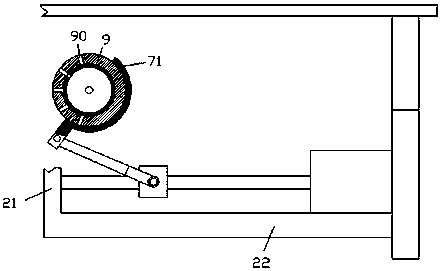

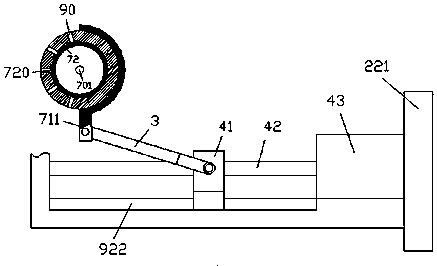

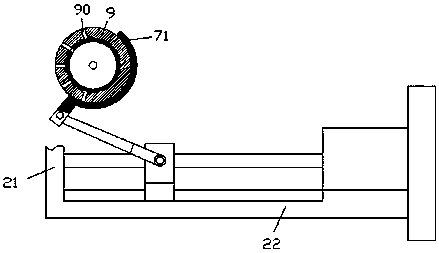

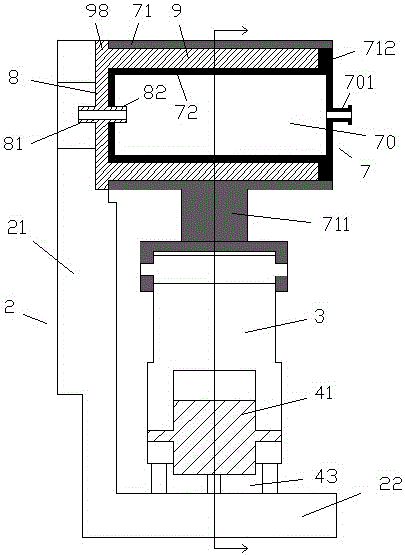

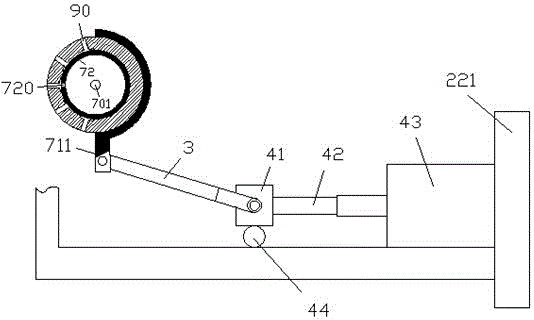

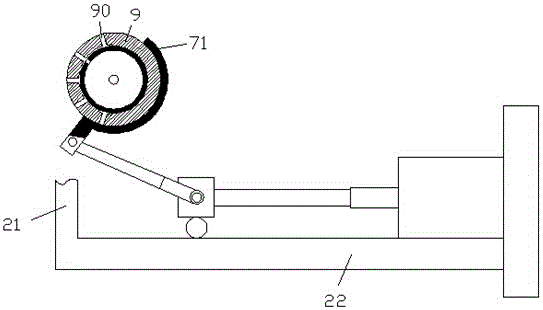

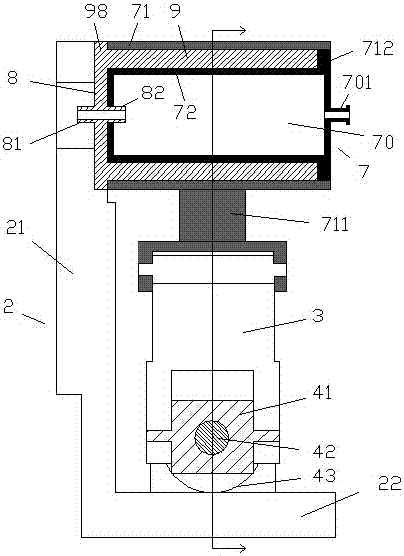

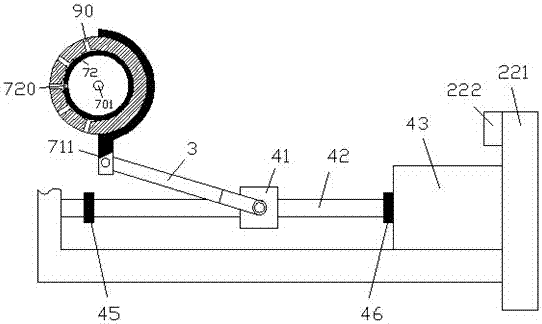

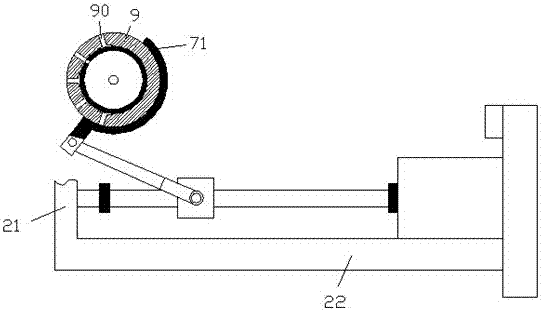

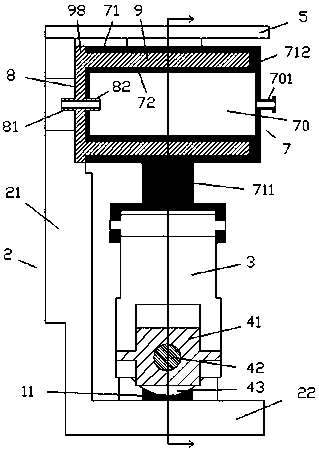

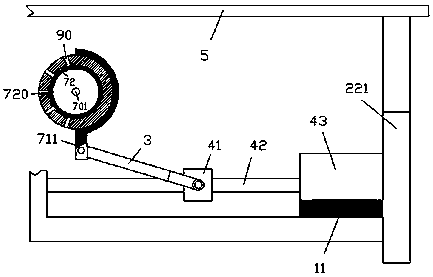

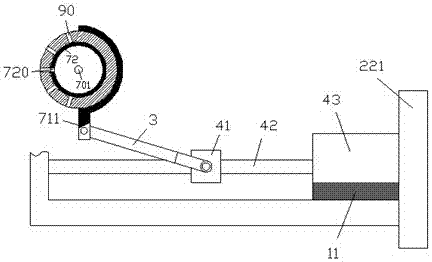

Provided is a dust-proof shock-absorbing type air conditioner condensate water drain device. The dust-proof shock-absorbing type air conditioner condensate water drain device comprises a frame body (2) formed by a lengthwise frame body part (22) and an installation vertical frame part (21), an adjusting motor (43) which is fixedly installed on the lengthwise frame body part (22) and a condensate water jet device which is installed on the installation vertical frame part (21); the left end of the lengthwise frame body part (22) is fixedly connected with the installation vertical frame part (21), and a substrate fixed connecting part (221) which is used for being fixedly connected with a fixed substrate is arranged at the right end of the lengthwise frame body part (22); a protective cover (5) is arranged on the tops of the installation vertical frame part (21) and the substrate fixed connecting part (221), and the protective cover (5) is located above the condensate water jet device and the adjusting motor (43) and used for preventing dust from falling and stacking on the condensate water jet device and the adjusting motor (43).

Owner:湖南汨罗循环经济产业园区科技创新服务中心

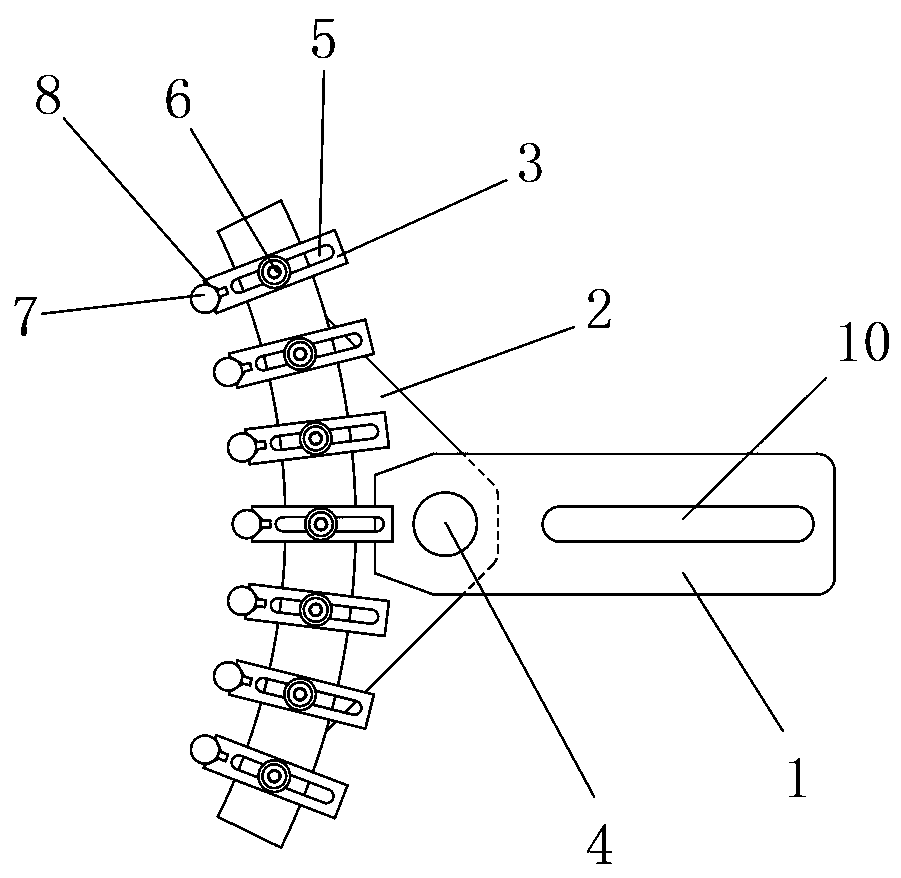

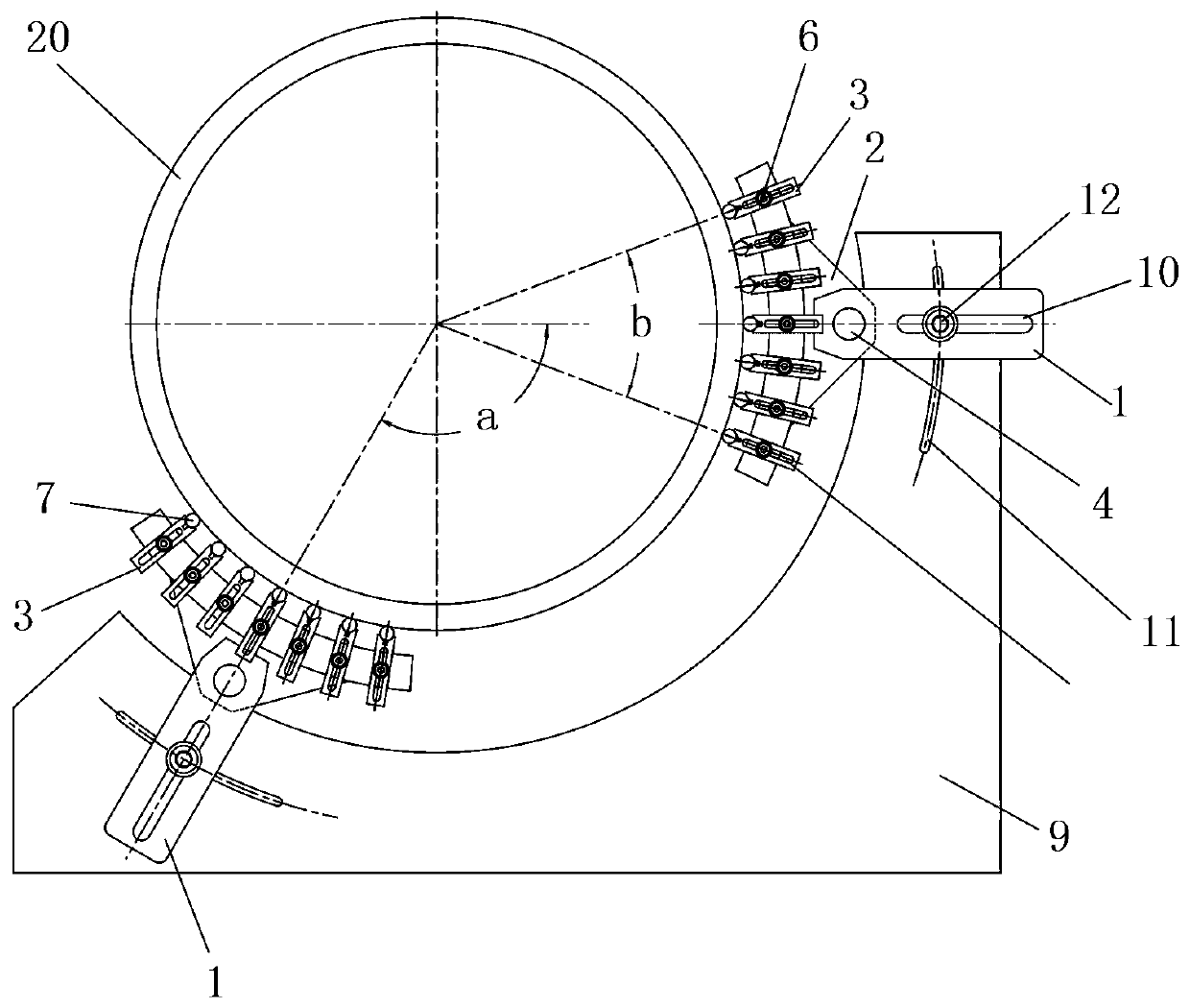

Multi-contact-point floatable electromagnetic centerless fixture support

The invention discloses a multi-contact-point floatable electromagnetic centerless fixture support. The multi-contact-point floatable electromagnetic centerless fixture support comprises a supportingbody, a support frame and a plurality of support heads; the support frame is rotatably fixed to the supporting body, the plurality of support heads are arranged on the support frame in a circular-arcmode, and the support heads and the support frame are slidably connected in the diameter direction of a circular arc; and hard round rods are arranged at the front ends of the support heads, and the axes of the hard round rods are perpendicular to the axes of the support heads.

Owner:上海特安一凯轴承有限公司

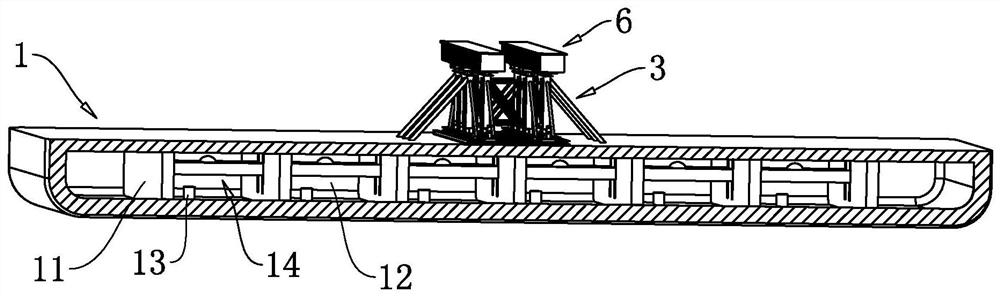

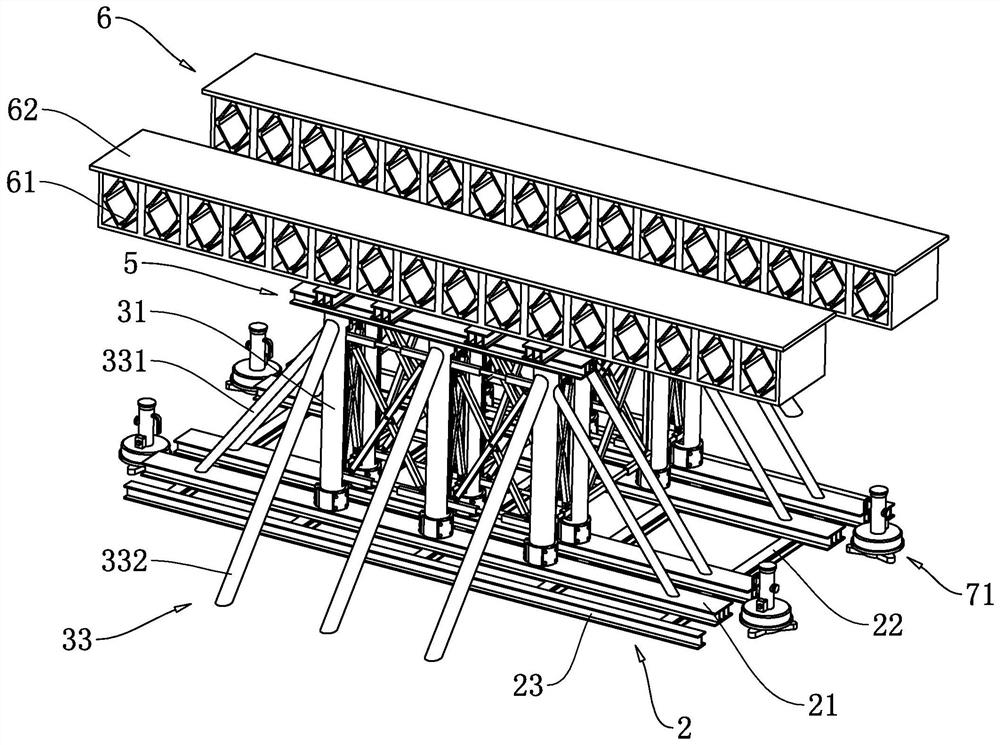

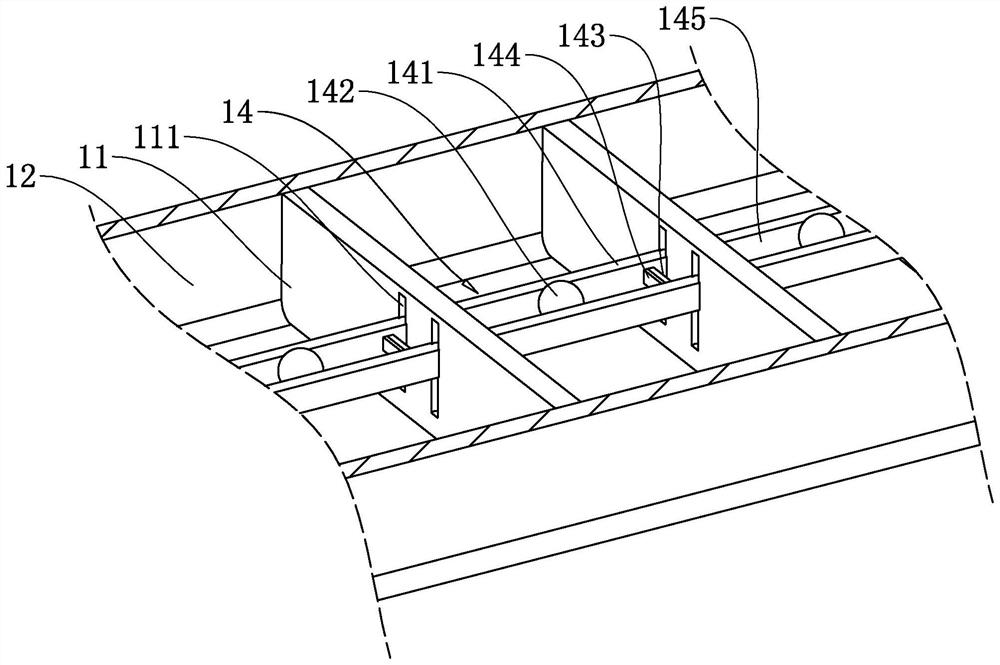

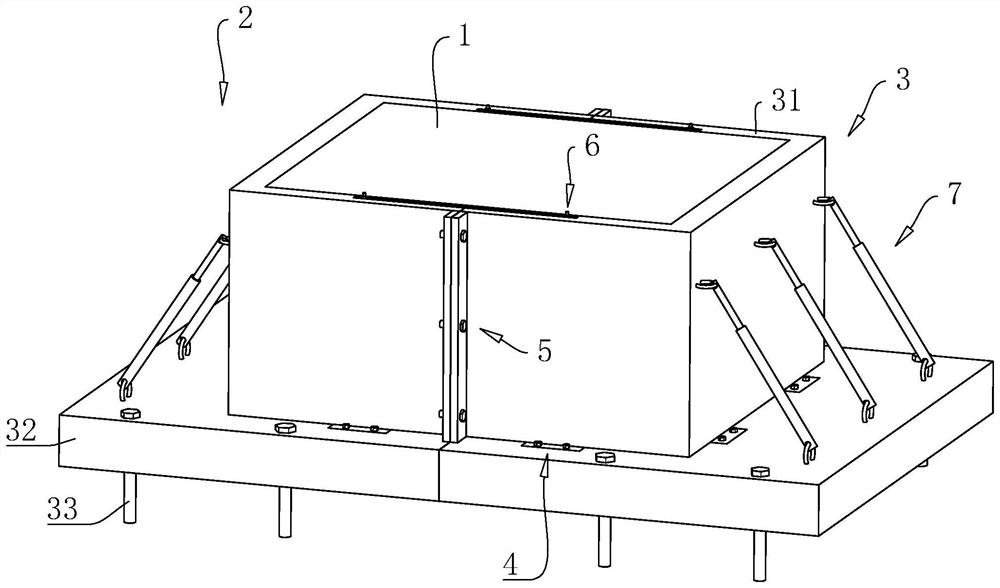

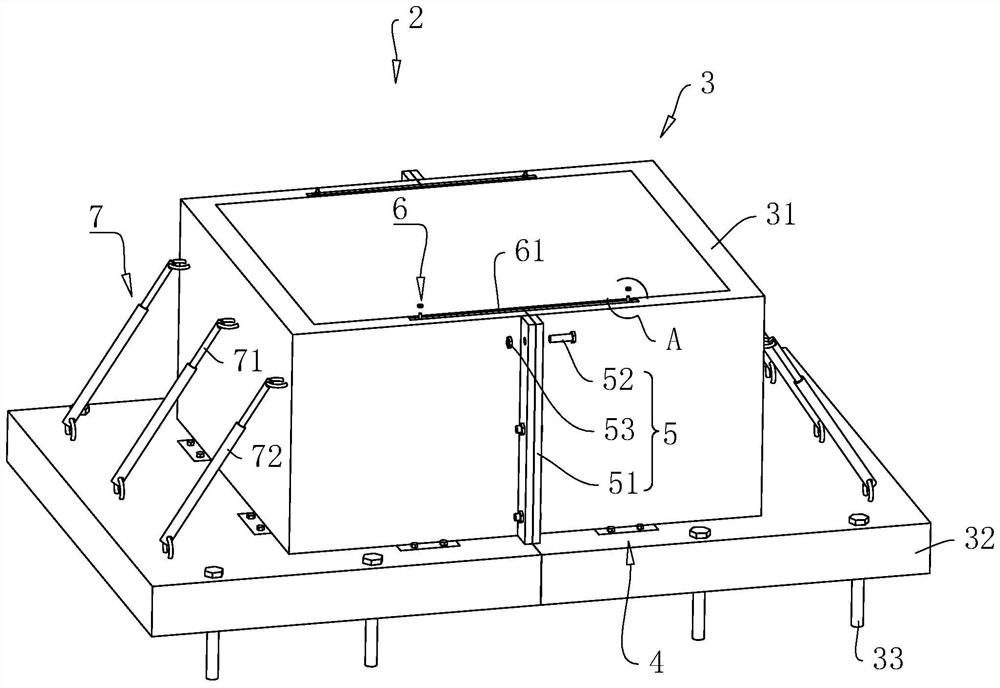

Movable supporting device for river-crossing bridge construction

ActiveCN113373824AStable structureEnsure safetyWaterborne vesselsBridge erection/assemblyMechanical engineeringDeck

The invention relates to a movable supporting device for river-crossing bridge construction, and belongs to the field of bridge construction equipment.The movable supporting device comprises a ship body and a supporting set frame fixed to a deck of the ship body, a main distribution supporting assembly is arranged between the supporting set frame and the ship body, and the supporting set frame is fixed to the main distribution supporting assembly; the main distribution supporting assembly comprises a plurality of longitudinal distribution beams and transverse distribution beams, the longitudinal distribution beams are arranged in parallel and fixedly connected with the ship body, the transverse distribution beams are located on the sides, away from the ship body, of the longitudinal distribution beams, and the transverse distribution beams are perpendicularly and fixedly connected with the longitudinal distribution beams. The supporting device has the effects of reinforcing the ship body, enabling the structure of the ship body to be more stable and better providing supporting, floating towing loads can be evenly transmitted to the ship body, the safety of the ship body is guaranteed, stress on the ship body is more uniform, and supporting is better provided for a bridge structure.

Owner:JIANGSU BAIGU STEEL STRUCTURE ENG

Sponge plot wall-leaning seepage well system

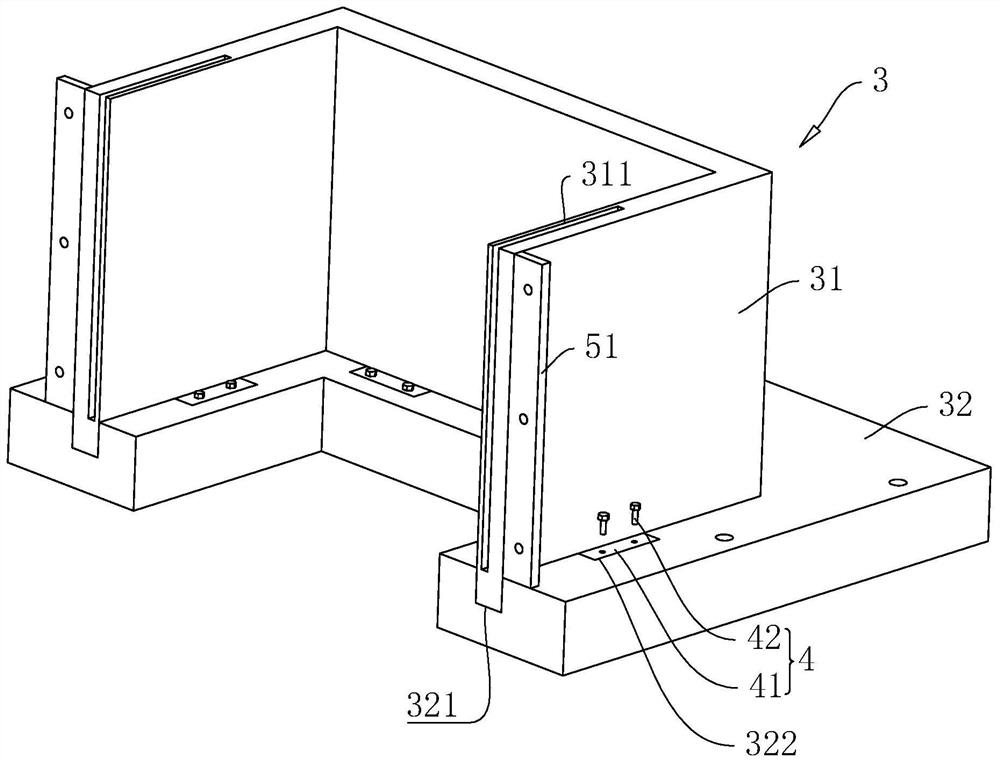

PendingCN114411924AReduce cracking and even breakageEffective isolationSewerage structuresClimate change adaptationMechanical engineeringWater seepage

The invention relates to a sponge community wall seepage well system, and relates to the technical field of seepage well systems, the sponge community wall seepage well system comprises a water seepage system arranged on the ground and a supporting device arranged around the periphery of the water seepage system, and the supporting device comprises two symmetrical supporting mechanisms and a locking mechanism used for connecting the two supporting mechanisms; each supporting mechanism comprises a containing plate, a bottom supporting plate and a positioning piece, the containing plates are arranged on the bottom supporting plates, and the positioning pieces are used for fixing the bottom supporting plates to the ground; the side walls, close to each other, of the two containing plates abut against each other, the locking mechanism is used for connecting the two abutting containing plates, and the two abutting containing plates are used for supporting a water seepage system. The seepage well system has the effect of improving the application stability of the seepage well system.

Owner:广东定源项目管理有限公司

A dust-proof air conditioner condensate discharge device

ActiveCN105157200BReduce adverse effectsReduce the amount of waterCondensate preventionSprayerEngineering

Owner:HAO WEI ENVIRONMENTAL TECH NANTONG CO LTD

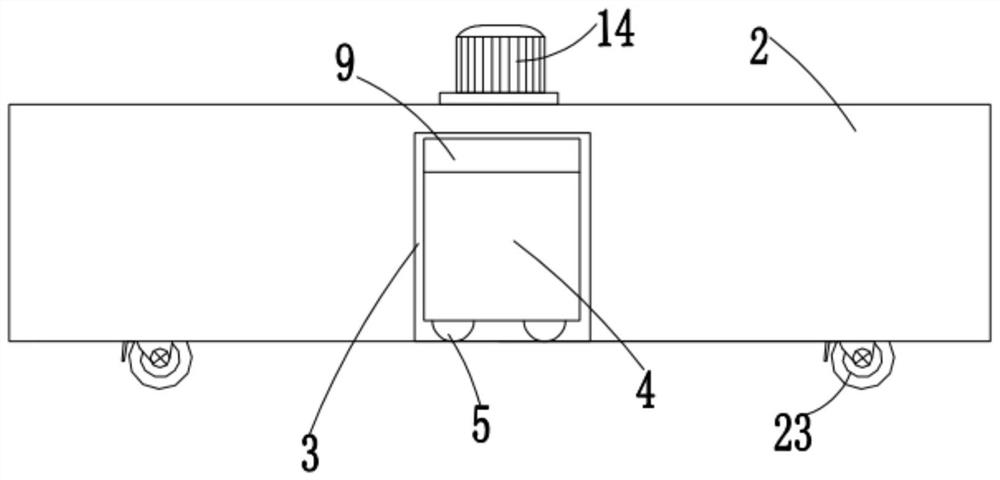

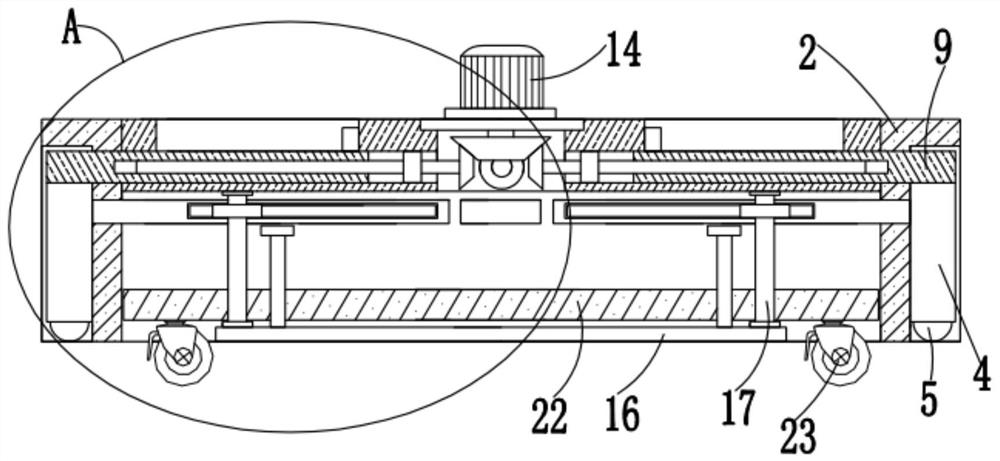

Automatic feeding and discharging equipment

PendingCN112722679AIncrease the support areaImprove support stabilityManual conveyance devicesEngineeringStructural engineering

Owner:厦门斯科钛自动化科技有限公司

Y-direction four-guide-rail structure

PendingCN112460144AAvoid occupyingAvoid run stabilityLinear bearingsDirt cleaningStructural engineeringMechanical engineering

Owner:中山市智合数控科技有限公司

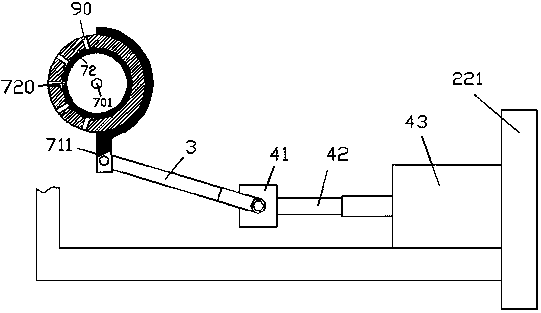

An air conditioner condensate discharge device with guide chute

ActiveCN105222316BReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusAir conditioning

An air conditioner condensate discharge device with a guide sliding groove comprises a frame (2), an adjusting motor (43) and a condensate spraying device, wherein the frame (2) is composed of a longitudinal long frame part (22) and a vertical mounting frame part (21); the adjusting motor (43) is fixedly mounted on the longitudinal long frame part (22); the condensate spraying device is mounted on the vertical mounting frame part (21); the left end of the longitudinal long frame part (22) is fixedly connected with the vertical mounting frame part (21).

Owner:湖南汨罗循环经济产业园区科技创新服务中心

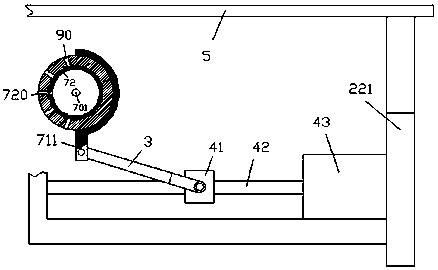

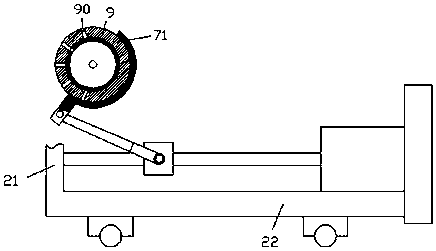

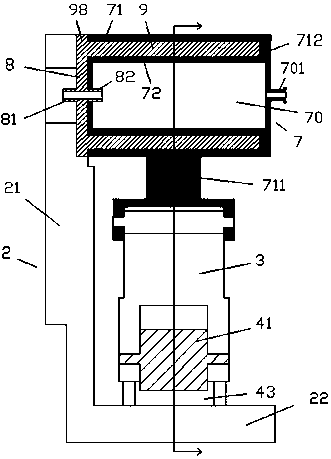

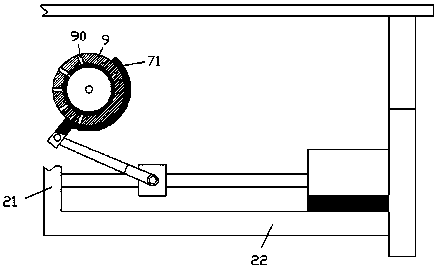

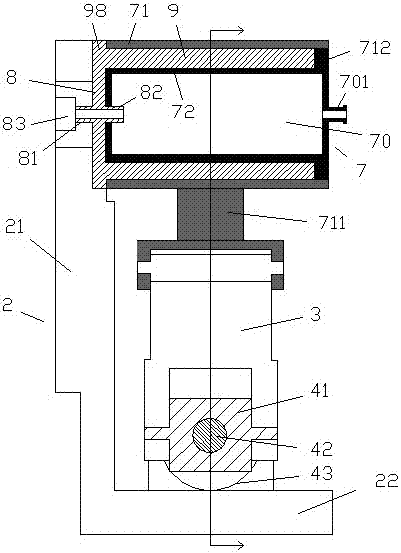

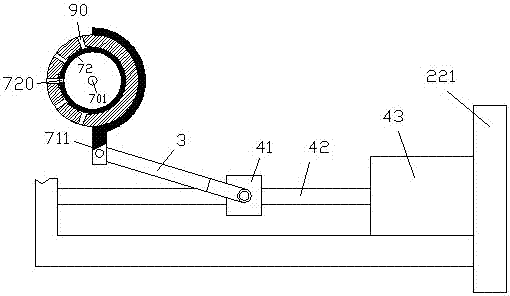

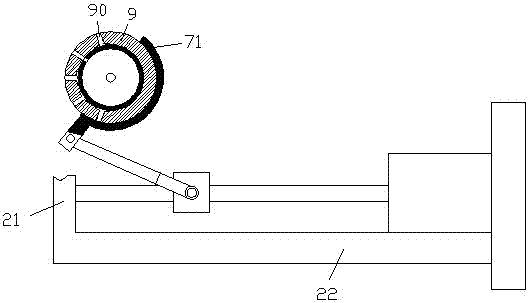

Air conditioner condensate water discharging device with moving rolling wheel

ActiveCN105066413AReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusHydraulic cylinderWater discharge

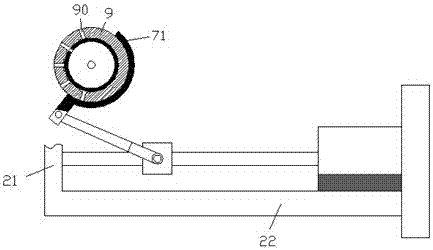

The invention discloses an air conditioner condensate water discharging device with a moving rolling wheel. The air conditioner condensate water discharging device with the moving rolling wheel comprises a frame body (2) comprising a longitudinal long frame body part (22) and an installation vertical frame part (21), a hydraulic cylinder (43) fixedly arranged on the longitudinal long frame body part (22), and a condensate water injection device arranged on the installation vertical frame part (21), wherein the left end of the longitudinal long frame body part (22) is fixedly connected with the installation vertical frame part (21); and the right end of the longitudinal long frame body part (22) is fixedly provided with a base body fixed connection part (221) which is fixedly connected with a fixed base body.

Owner:中山中松电器有限公司

An air conditioner condensate discharge device with led indicator light

InactiveCN105091294BReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusEngineeringAir conditioning

Owner:佛山市顺德区俊东诺达电器有限公司

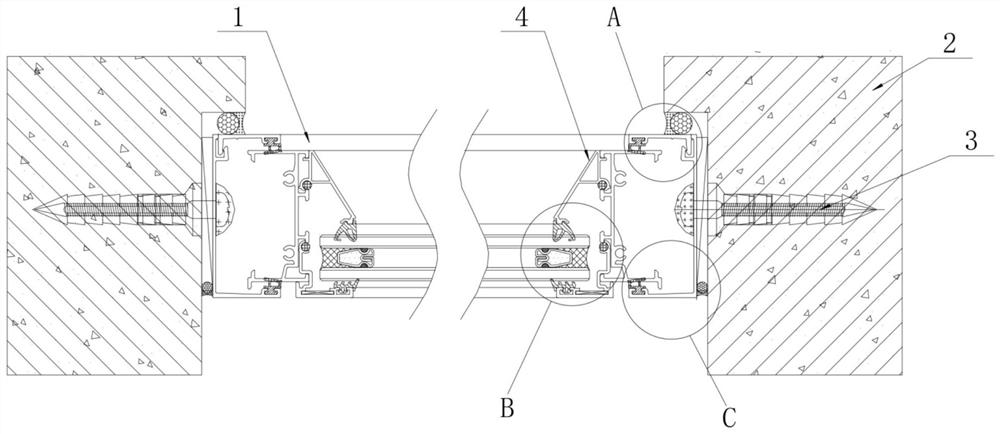

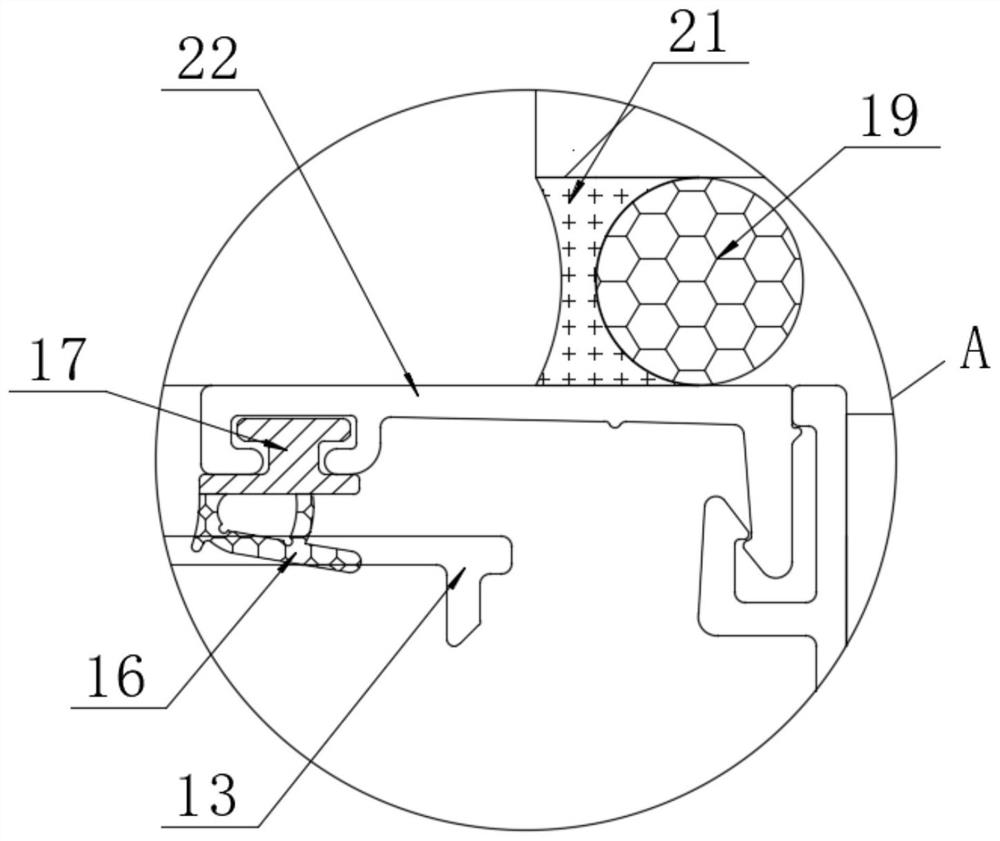

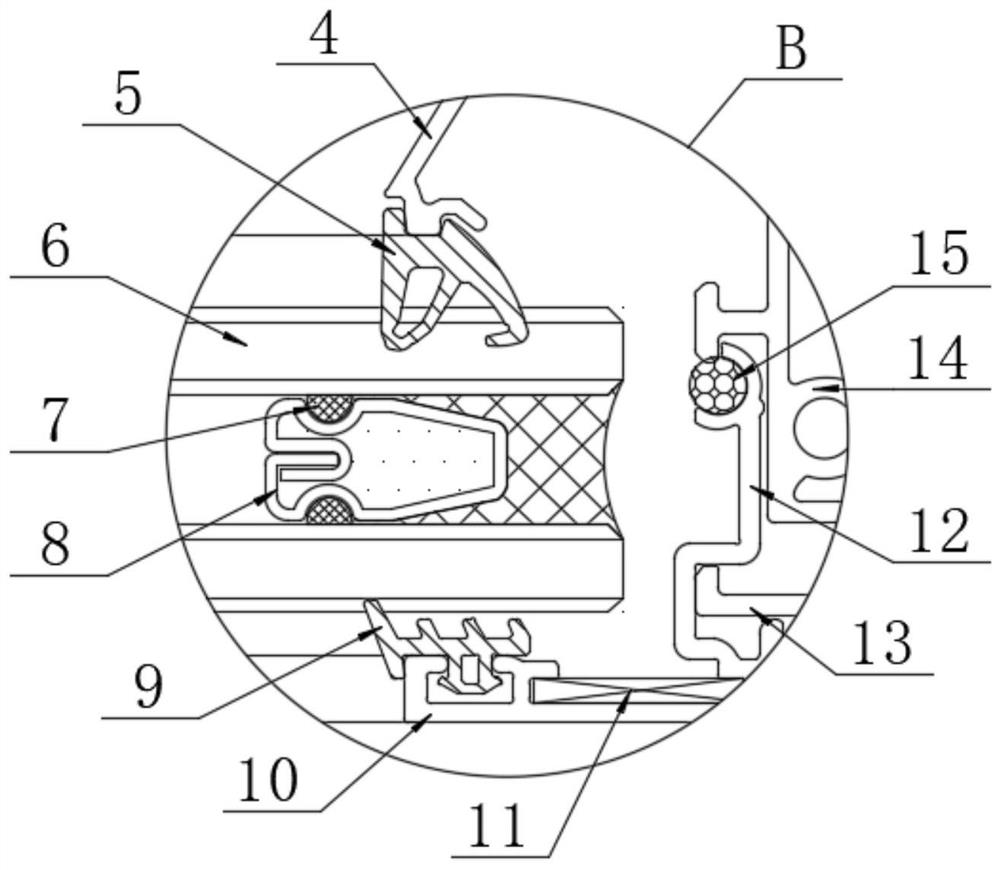

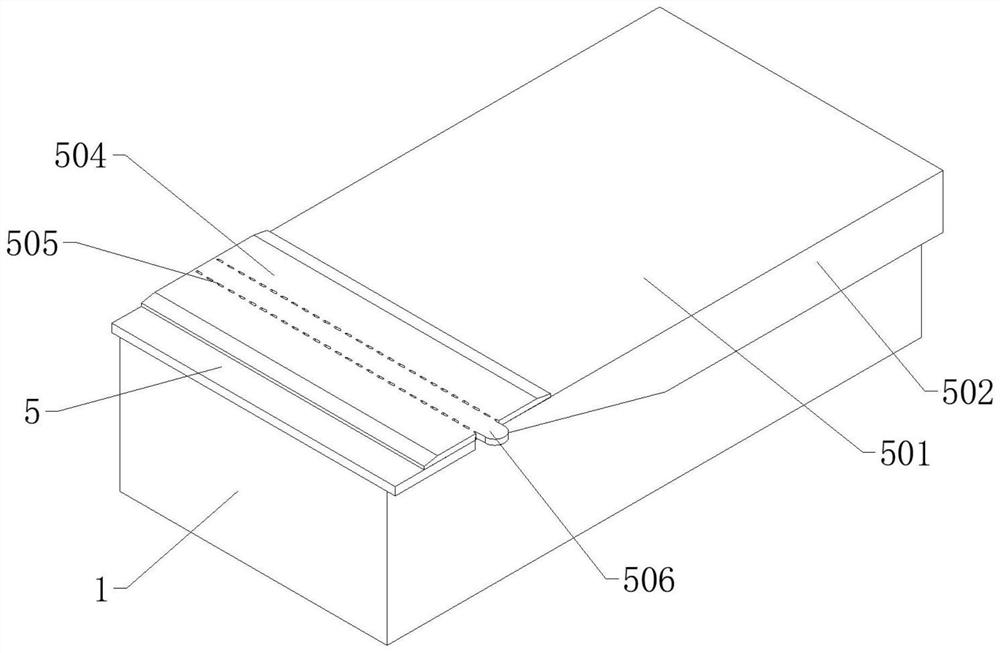

Installation mode of preassembled door and window auxiliary frame

PendingCN113404406AQuick assemblyAchieving gap closure requiresFrame fasteningJoints tightening/coveringWindow sillMechanical engineering

The invention discloses an installation mode of a preassembled door and window auxiliary frame, and belongs to the technical field of door and window auxiliary frame installation. Specifically, the installation mode comprises the steps that auxiliary frame connecting members are preassembled and embedded, a door and window plate is movably clamped between the auxiliary frame connecting members on the two sides, clamp supporting ribs are fixedly connected to the two sides of the bottom of the door and window plate, and first limiting buckles are movably clamped at the bottoms of the clamp supporting ribs. According to the installation mode, through the designed clamp supporting members, after the clamp supporting members are assembled and connected to the auxiliary frame connecting members through line pressing buckles on the two sides, rapid assembly of the line pressing buckles and the auxiliary frame connecting members can be achieved, moreover, rapid assembly and lightweight design of the embedded hole in one side can be achieved through the clamp supporting members and cavities of the inner cavities of the auxiliary frame connecting members, and then, the assembly requirements of the door and window plate can be effectively improved; and meanwhile, the requirement for sealing a gap between the door and window plate and the embedded hole can be met through a sealing waterproof pad and waterproof glue on one side, and the situation that the durability use requirement is affected by water seepage of a window sill of the door and window plate is avoided.

Owner:FOSHAN KETE ALUMINUM PROD CO LTD

Early diagnosis kit for colorectal cancer liver metastases

ActiveCN114148610BGuaranteed placement stabilityImprove protectionContainers to prevent mechanical damageDischarging meansCardboardCarton

The invention discloses a kit for early diagnosis of liver metastasis of colorectal cancer, which belongs to the field of medical diagnosis and treatment kits. The kit for early diagnosis of liver metastasis of colorectal cancer comprises fixed cardboard, movable cardboard one and movable cardboard two arranged inside the carton, and The right end of the movable cardboard 2 is inserted in the inside of the through slot, and the movable cardboard 1 can be turned over by pulling the movable cardboard 2, so that the reagent tube can be erected, and the reagent tube does not need to be picked up manually, which effectively improves the convenience of the reagent tube. In addition, the device adopts paper material components as a whole to realize the stable placement of reagent tubes and product packaging, while reducing the production cost of the device, it can also effectively protect the environment, and to a certain extent, it is conducive to the decomposition and recycling of the device.

Owner:连云港市第二人民医院

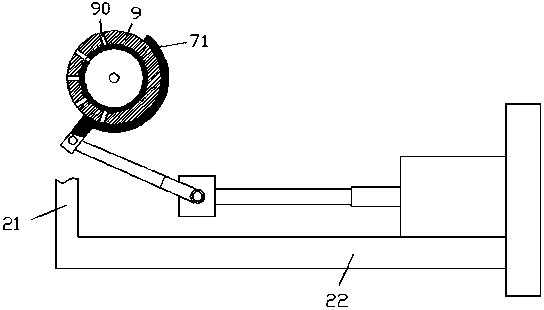

Adjustable air conditioner condensate water drainage device

ActiveCN105115140AReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusStand/rackMechanical engineering

An adjustable air conditioner condensate water drainage device comprises a rack (2) formed by a lengthwise rack portion (22) and a mounting stand rack portion (21), an adjusting motor (43) fixedly mounted on the lengthwise rack portion (22), and a condensate water spraying device mounted on the mounting stand rack portion (21). The left end of the lengthwise rack portion (22) is fixedly connected with the mounting stand rack portion (21).

Owner:枣庄市信百瑞家具股份有限公司

Heat radiation type air conditioner condensate water discharging device with guide sliding slot

ActiveCN105157201AReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusWater dischargeMarine engineering

The invention discloses a heat radiation type air conditioner condensate water discharging device with a guide sliding slot. The heat radiation type air conditioner condensate water discharging device with the guide sliding slot comprises a frame body (2) comprising a lengthwise frame body part (22) and an installation vertical frame part (21), and also comprises an adjusting motor (43) fixedly arranged on the lengthwise frame body part (22), and a condensate water ejection device arranged on the installation vertical frame part (21), wherein the left end of the lengthwise frame body part (22) is fixedly connected with the installation vertical frame part (21); the right end of the lengthwise frame body part (22) is fixedly provided with a base body fixed connection part (221) fixedly connected with the fixed base body.

Owner:湖南汨罗循环经济产业园区科技创新服务中心

Mobile air conditioner condensate discharge device

ActiveCN105222317AReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusEngineering

A mobile air conditioner condensate discharge device comprises a frame (2), an adjusting motor (43) and a condensate spraying device, wherein the frame (2) is composed of a longitudinal long frame part (22) and a vertical mounting frame part (21); the adjusting motor (43) is fixedly mounted on the longitudinal long frame part (22); the condensate spraying device is mounted on the vertical mounting frame part (21); the left end of the longitudinal long frame part (22) is fixedly connected with the vertical mounting frame part (21).

Owner:SHANDONG BOCHEN HYDRAULIC MASCH CO LTD

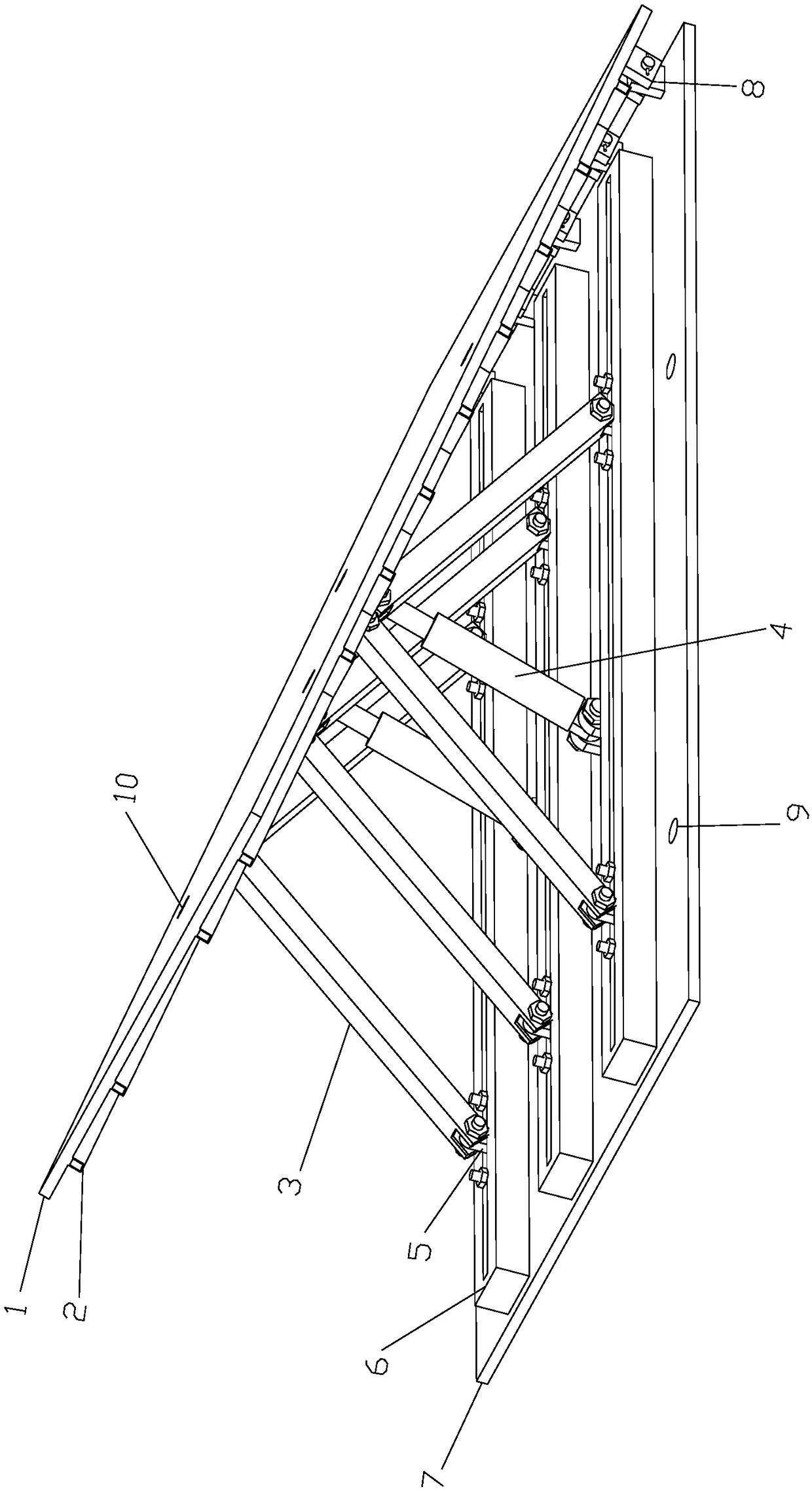

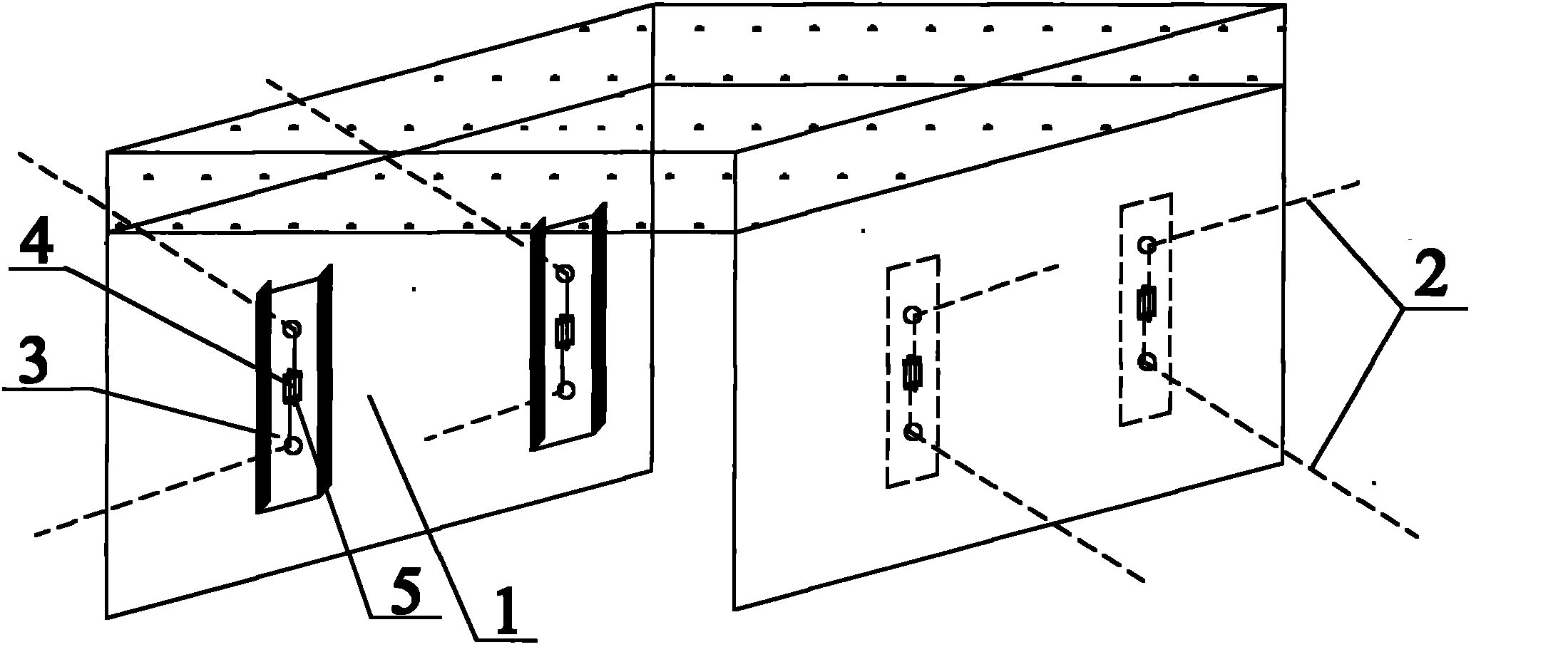

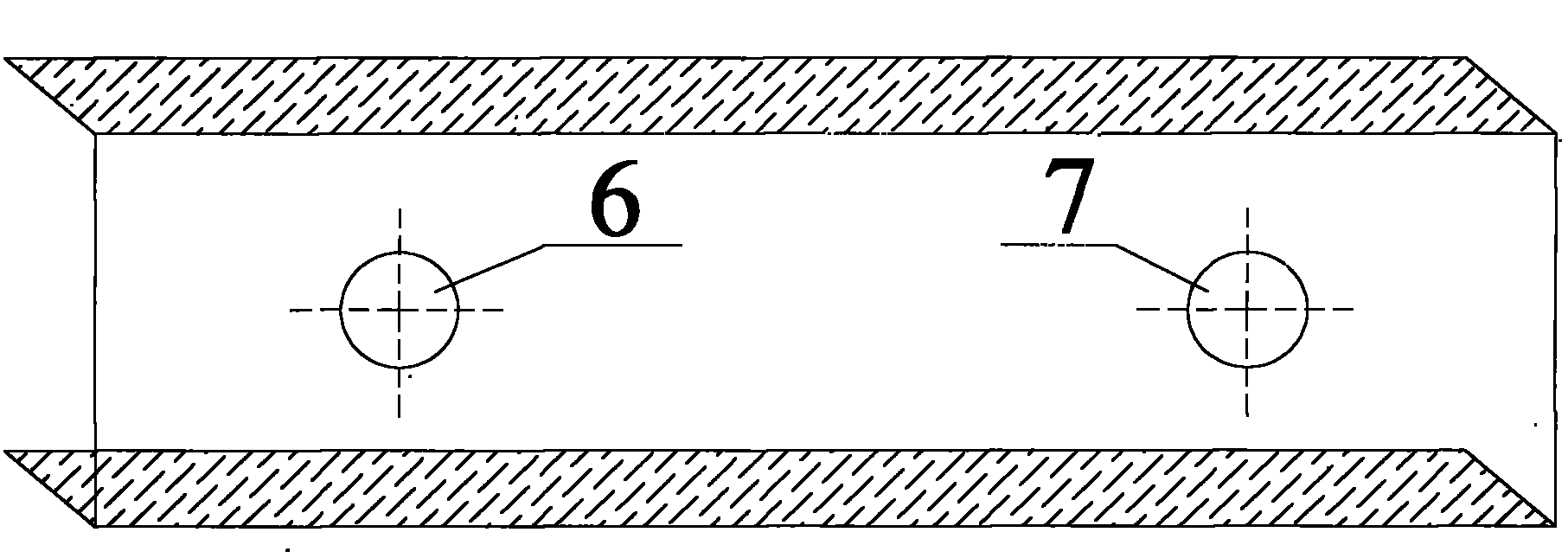

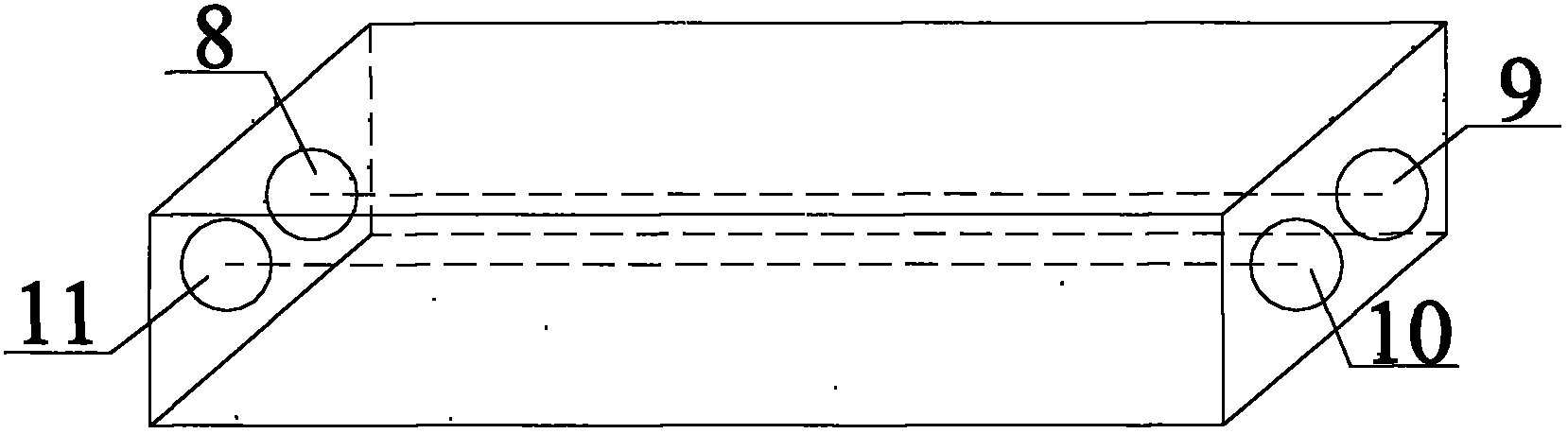

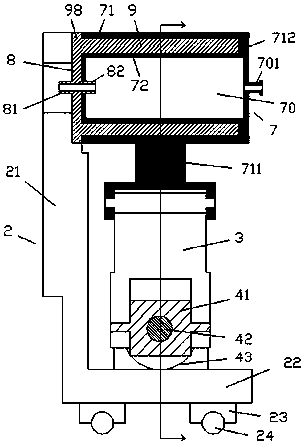

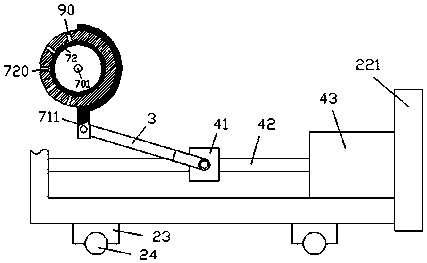

Structure and method for preventing large deformation slippage of lateral wall of high stress tunnel

InactiveCN102704968AGuarantee support stabilityEasy processing and installationAnchoring boltsPre stressHigh intensity

The invention provides a structure and a method for preventing large deformation slippage of a lateral wall of a high stress tunnel. The structure comprises a high stress tunnel wall, high-strength low-looseness large-diameter anchor ropes, a channel steel, a rectangular coupler and a lockset, wherein the high stress tunnel top and bottom plate surrounding rock and two walls are combined into one integrated body by arranging a plurality of high-strength low-looseness large-diameter anchor ropes which are connected with wall control devices; the port exposed parts of the upper and lower inclined anchor ropes penetrate through the metal channel steels and the rectangular coupler sequentially; double-port metal channel steels are fastened at the central area of the high stress tunnel wall after the anchor ropes exert a high stress; and the rectangular coupler is fastened and adhered to the internal central part of the metal channel steel, so that the coal layer compression strength of the lateral wall of the high stress tunnel is enhanced, the large deformation slippage of the coal rock at the lateral wall is restricted; the support stability of two walls of the high stress tunnel is ensured; and the whole structure is simple and reasonable, high in security coefficient, convenient in material machining and installation, low in cost, and good in effect and has wide practicability and popularization values.

Owner:CHINA UNIV OF MINING & TECH

A mobile air-conditioning condensate discharge device

ActiveCN105222317BReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusEngineering

A mobile air conditioner condensate discharge device comprises a frame (2), an adjusting motor (43) and a condensate spraying device, wherein the frame (2) is composed of a longitudinal long frame part (22) and a vertical mounting frame part (21); the adjusting motor (43) is fixedly mounted on the longitudinal long frame part (22); the condensate spraying device is mounted on the vertical mounting frame part (21); the left end of the longitudinal long frame part (22) is fixedly connected with the vertical mounting frame part (21).

Owner:SHANDONG BOCHEN HYDRAULIC MASCH CO LTD

A hydraulically driven air conditioning condensate discharge device

ActiveCN105222313BReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusHydraulic cylinderEngineering

A hydraulic drive air conditioner condensate water drainage device comprises a frame body (2), a hydraulic cylinder (43) and a condensate water spraying device, wherein the frame body (2) is composed of a longitudinal frame body part (22) and a vertical frame installation part (21); the hydraulic cylinder (43) is fixedly installed on the longitudinal frame body part (22); the condensate water spraying device is installed on the vertical frame installation part (21); the left end of the longitudinal frame body part (22) is fixedly connected with the vertical frame installation part (21); the right end of the longitudinal frame body part (22) is provided with a base body fixed connection part (221) fixedly connected with a fixed base body.

Owner:增城市家家乐电器有限公司

Air conditioner condensate water drainage device with separation net and limiting sensor

ActiveCN105135655AReduce adverse effectsReduce the amount of waterSpace heating and ventilation safety systemsCondensate preventionEngineeringWater spray

Owner:湖州佳灏信息技术有限公司

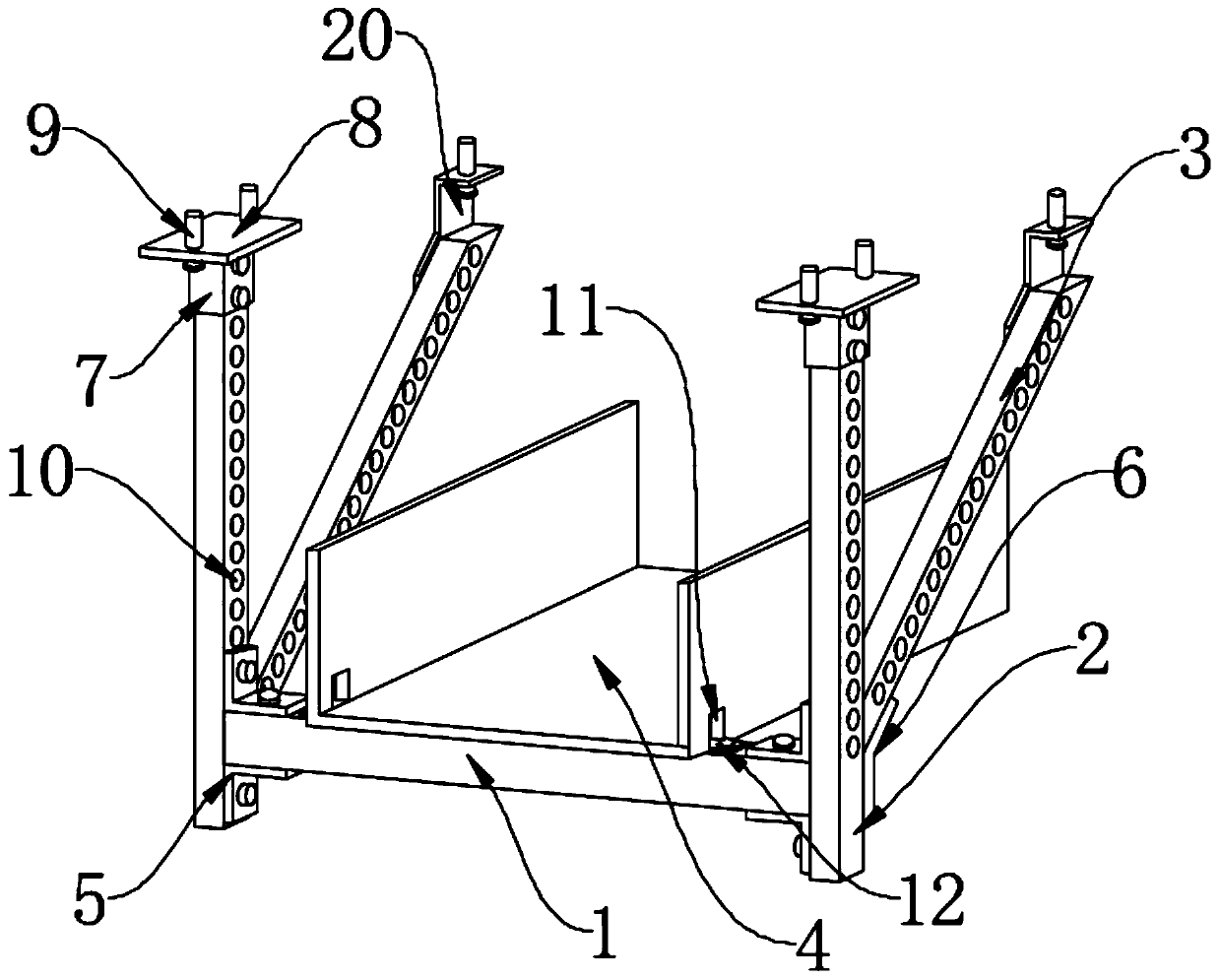

Steel structure bridge for building construction

InactiveCN111193229ASolve the problem that the stability performance is not perfect enough, and the practicability is not good enoughEasy to assembleElectrical apparatusJoint (building)Building construction

The invention discloses a steel structure bridge frame for building construction, relates to the technical field of bridge frames, and aims to solve the problems that an existing steel structure bridge frame for building construction is not perfect enough in mounting and fixing stability and not good enough in practicability. Side edge supporting mounting vertical rods are mounted on the two sidesof a fixed main supporting transverse rod correspondingly. Fixed mounting inclined rods are mounted at the rear ends of the two side edge supporting mounting vertical rods; a bridge frame fixing frame is mounted above the fixed main supporting transverse rod; and mounting limiting blocks are mounted at the two ends of the joint of the fixed main supporting transverse rod and the side edge supporting mounting vertical rods correspondingly. Second limiting installation blocks is installed at the joint of the side edge supporting mounting vertical rods and the fixed mounting inclined rods, an upper installation fixing sleeve is installed on the outer side of the upper end of the side edge supporting mounting vertical rods, a fixing platform is installed at the upper end of the upper installation fixing sleeve, and bevel edge fixing mechanisms are installed at the upper ends of the fixed mounting inclined rods.

Owner:邓婧

Dust-proof vibration-absorbing air-conditioning condensate discharge device

ActiveCN105115141BReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusMarine engineeringAir conditioning

Provided is a dust-proof shock-absorbing type air conditioner condensate water drain device. The dust-proof shock-absorbing type air conditioner condensate water drain device comprises a frame body (2) formed by a lengthwise frame body part (22) and an installation vertical frame part (21), an adjusting motor (43) which is fixedly installed on the lengthwise frame body part (22) and a condensate water jet device which is installed on the installation vertical frame part (21); the left end of the lengthwise frame body part (22) is fixedly connected with the installation vertical frame part (21), and a substrate fixed connecting part (221) which is used for being fixedly connected with a fixed substrate is arranged at the right end of the lengthwise frame body part (22); a protective cover (5) is arranged on the tops of the installation vertical frame part (21) and the substrate fixed connecting part (221), and the protective cover (5) is located above the condensate water jet device and the adjusting motor (43) and used for preventing dust from falling and stacking on the condensate water jet device and the adjusting motor (43).

Owner:湖南汨罗循环经济产业园区科技创新服务中心

An air conditioner condensate discharge device with a pipe connector

ActiveCN105135656BReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusWater dischargeElectric machine

Owner:南通新棉锦纺织品有限公司

A shock-absorbing air-conditioning condensate discharge device

ActiveCN105066412BReduce adverse effectsReduce the amount of waterCondensate preventionLighting and heating apparatusElectric machineEngineering

A shock-absorbing air-conditioning condensate discharge device, comprising a frame body (2) composed of a longitudinal frame body part (22) and a mounting stand part (21), fixedly installed on the longitudinal frame body part (22) The adjusting motor (43) on the top and the condensate spraying device installed on the installation stand part (21), the left end of the elongated frame body part (22) is fixedly connected with the installation stand part (21) .

Owner:湖州佳灏信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com