Schottky diode and manufacturing method thereof

A Schottky diode and electrode technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reduced conduction capacity and increased forward voltage of anti-surge capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to explain the overall concept of the present application more clearly, the following detailed description will be given by way of examples in combination with the accompanying drawings.

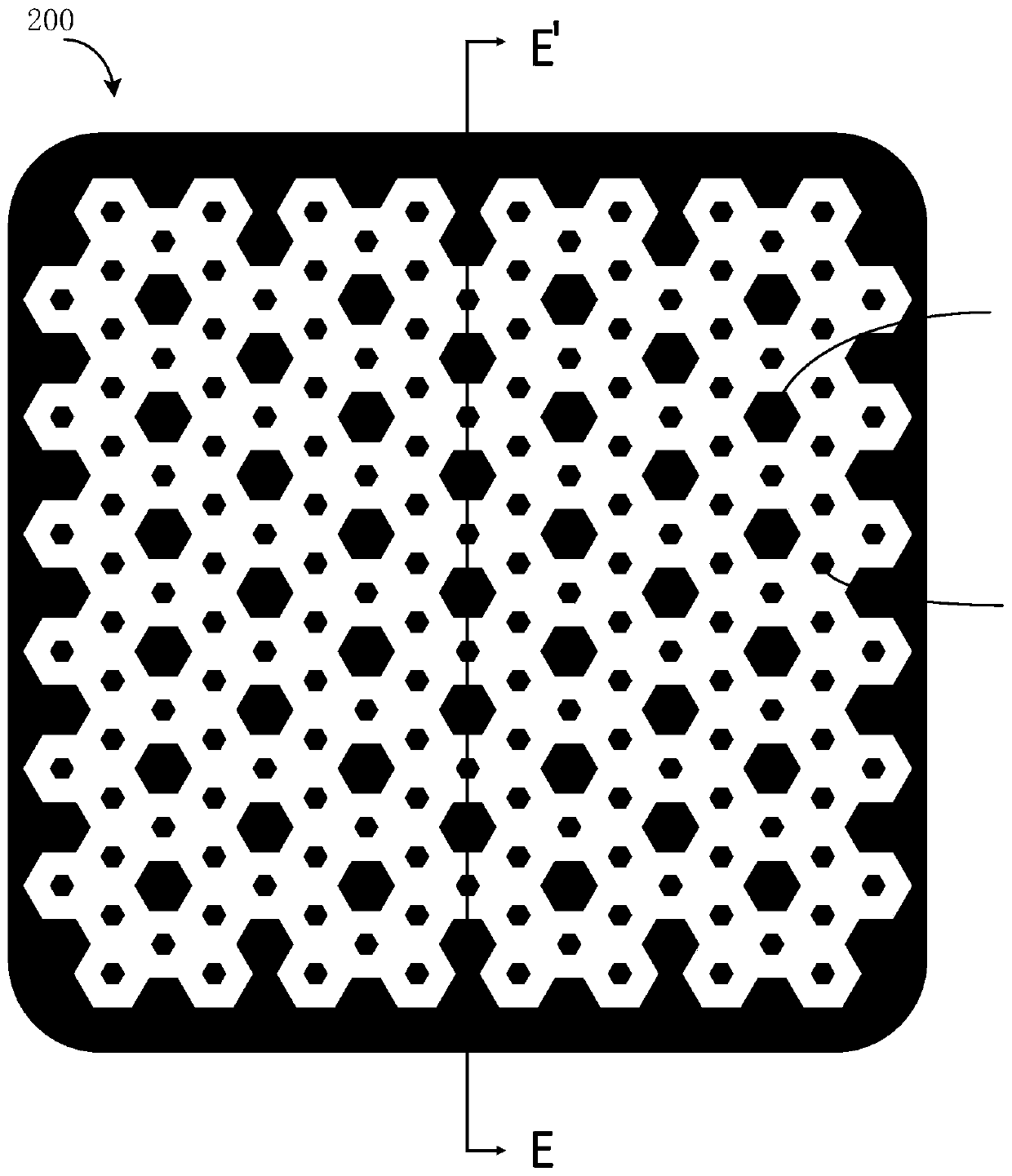

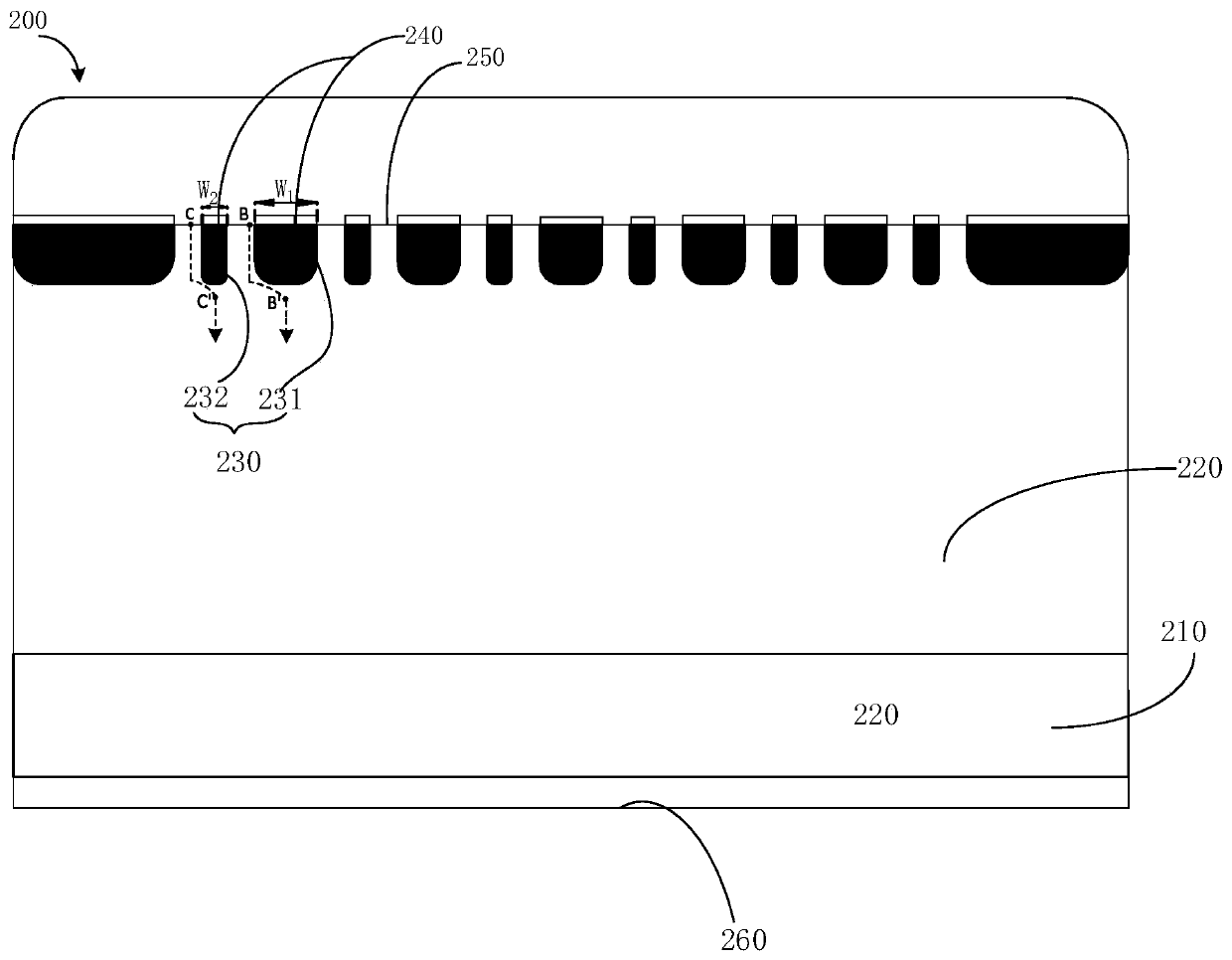

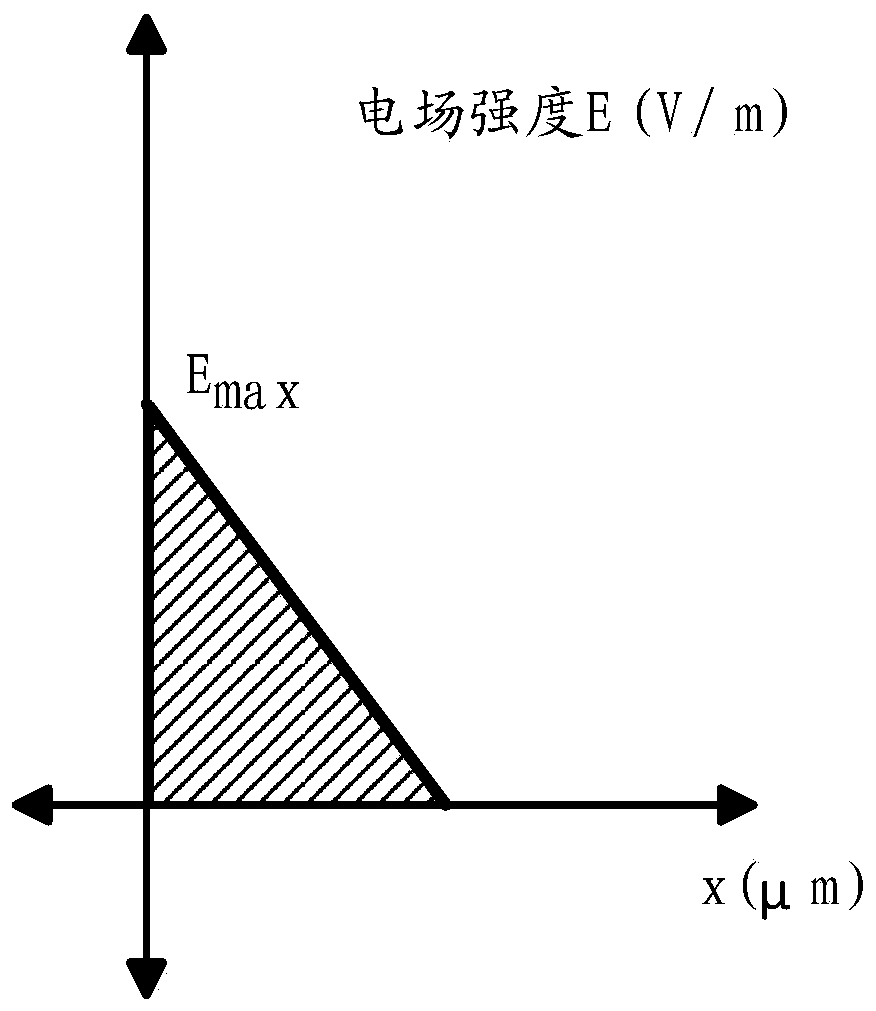

[0028] Schottky diodes in the prior art, in the case of normal current conduction, only Schottky participates in conduction, so the improvement of normal current conduction performance depends on the ratio of the Schottky junction area to the total area of the Schottky diode , the larger the proportion of the Schottky junction area to the total area of the Schottky diode, the better the forward conduction performance. In the case of a surge current impact, the voltage drop of the existing Schottky diode generally exceeds the built-in potential of the PN junction, causing the PN junction to be turned on, and the conductance modulation effect formed by the minority carrier injection of the PN junction can Reduce the resistance and conduction voltage drop of the device. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com