A rapid coagulation device for small wounds

A wound and fast technology, applied in the mechanical field, can solve the problems of long time consumption, low efficiency, and inability to achieve rapid hemostasis, and achieve the effect of high work efficiency and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

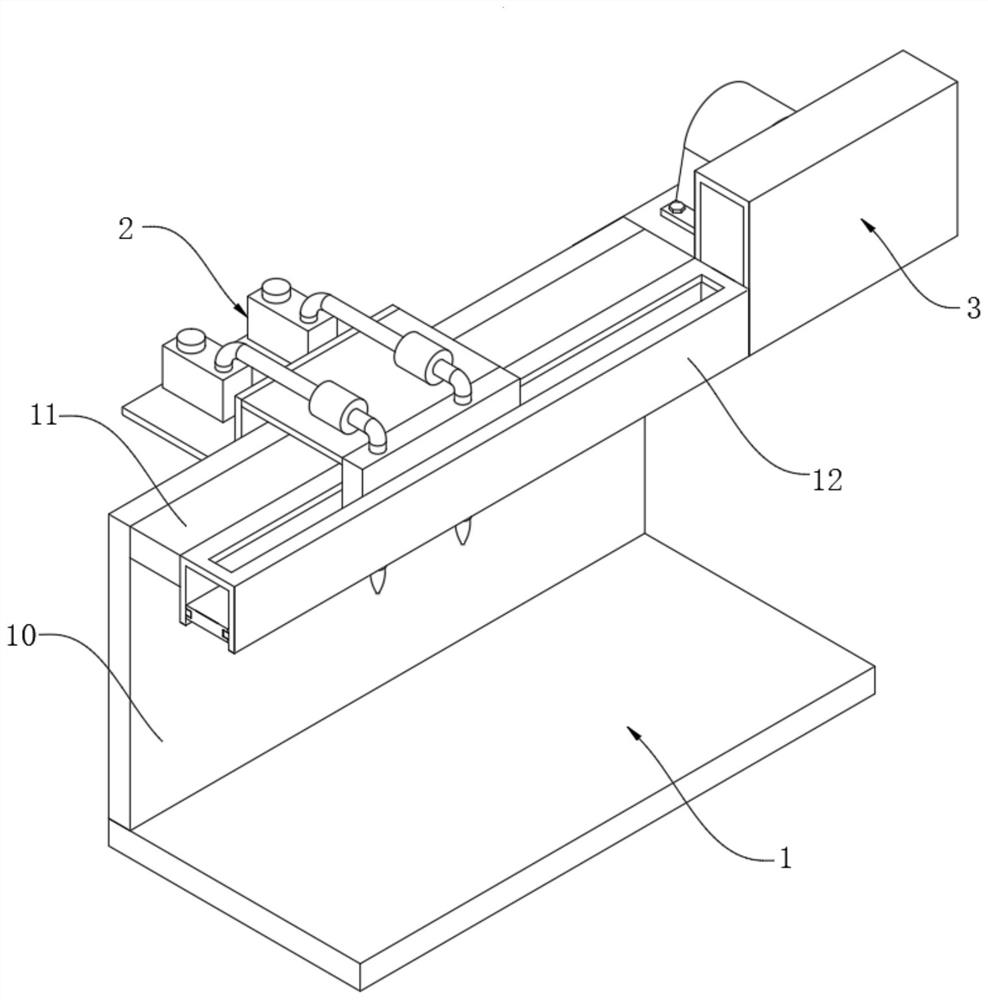

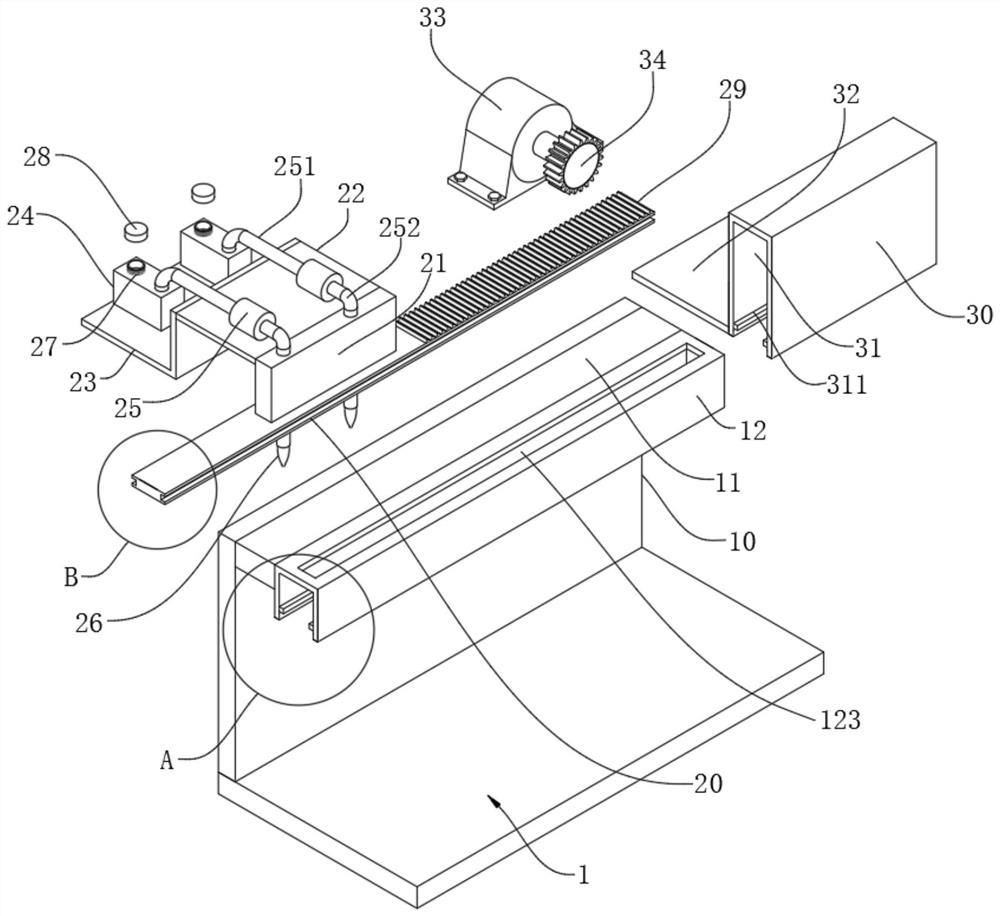

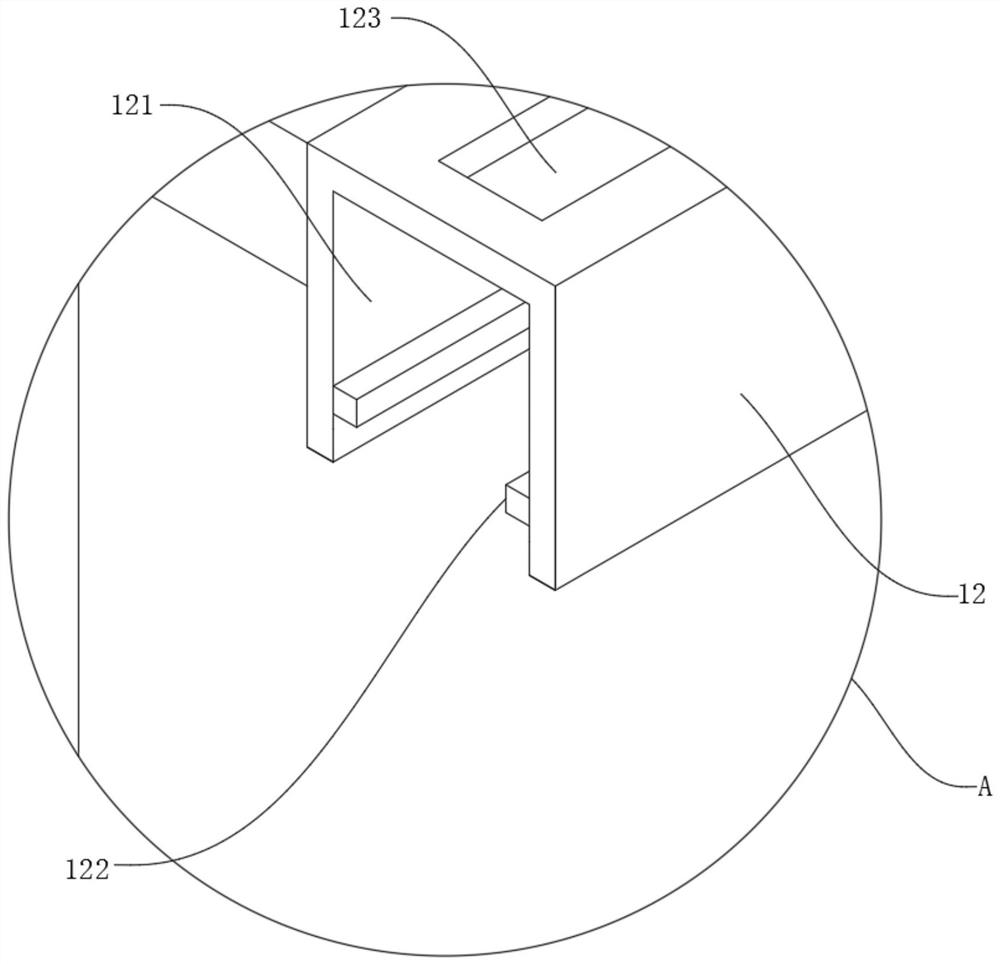

[0032] A small wound rapid coagulation device, such as Figure 1 to Figure 4 As shown, the base plate 1 is included, the base plate 1 is tightly welded with a vertical plate 10 distributed vertically, and the front side of the vertical plate 10 is tightly welded with a top plate 11 distributed horizontally, and the top plate 11 and the base plate 1 are located at On the same side of the vertical plate 10, a rectangular block 12 is tightly welded on the top plate 11, and a first rectangular groove 121 communicating with the outside world is also provided in the rectangular block 12, and the left and right sides of the first rectangular groove 121 are closely connected. The first slider 122 is welded, the top wall of the first rectangular groove 121 is provided with a first chute 123 communicating with the outside world, the rectangular block 12 is provided with a spraying treatment device 2, and the spraying treatment device 2 includes a The rectangular plate 20 in the first re...

Embodiment 2

[0041] As the second embodiment of the present invention, in order to be able to process the waste liquid for cleaning wounds, avoiding the random discharge of untreated waste liquid and causing pollution to the environment, the inventors made improvements to the bottom plate 1 as a preferred implementation For example Figure 5 and Figure 6 As shown, the base plate 1 is also provided with a number of water holes 4 arranged in a matrix and connected to the outside world. The upper surface of the base plate 1 is also tightly welded with a baffle plate 40, and the lower surface of the base plate 1 is tightly welded with a waste liquid collection. Case 41, water hole 4 is connected with waste liquid collection box 41, and waste liquid treatment box 42 is tightly welded on the back side of waste liquid collection box 41, is provided with cavity 421 in the waste liquid treatment box 42, and cavity 421 The filter screen 422 that is vertically distributed is tightly bonded on the w...

Embodiment 3

[0049] As a third embodiment of the present invention, in order to bandage the wound that has been hemostasis, and to avoid the growth of more bacteria on the wound healing adhesive plaster 541, causing secondary infection of the patient's wound, the inventor made a further step on the bottom plate 1 Improvement, as a preferred embodiment, such as Figure 7 and Figure 8 As shown, the right side of the bottom plate 1 is tightly welded with steel plates 5 that are distributed horizontally, and the steel plates 5 are provided with two mutually symmetrical arc blocks 50. A shaft hole 51 communicating with the outside world is provided, and a cutting blade 52 is tightly welded on one of the arc-shaped blocks 50. The cutting blade 52 is located between two arc-shaped blocks 50, and a rotating shaft is arranged between the two arc-shaped blocks 50 54, the end of the rotating shaft 54 is located in the shaft hole 51, the rotating shaft 54 is connected with the shaft hole 51, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com