Acoustic baffle composite structure for underwater detection equipment

A technology of underwater detection equipment and composite structure, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of interfering with the normal operation of underwater acoustic detection equipment, and consider the comprehensive performance of sound baffles in few sound field environments, so as to improve the detection performance of equipment, The effect of excellent sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

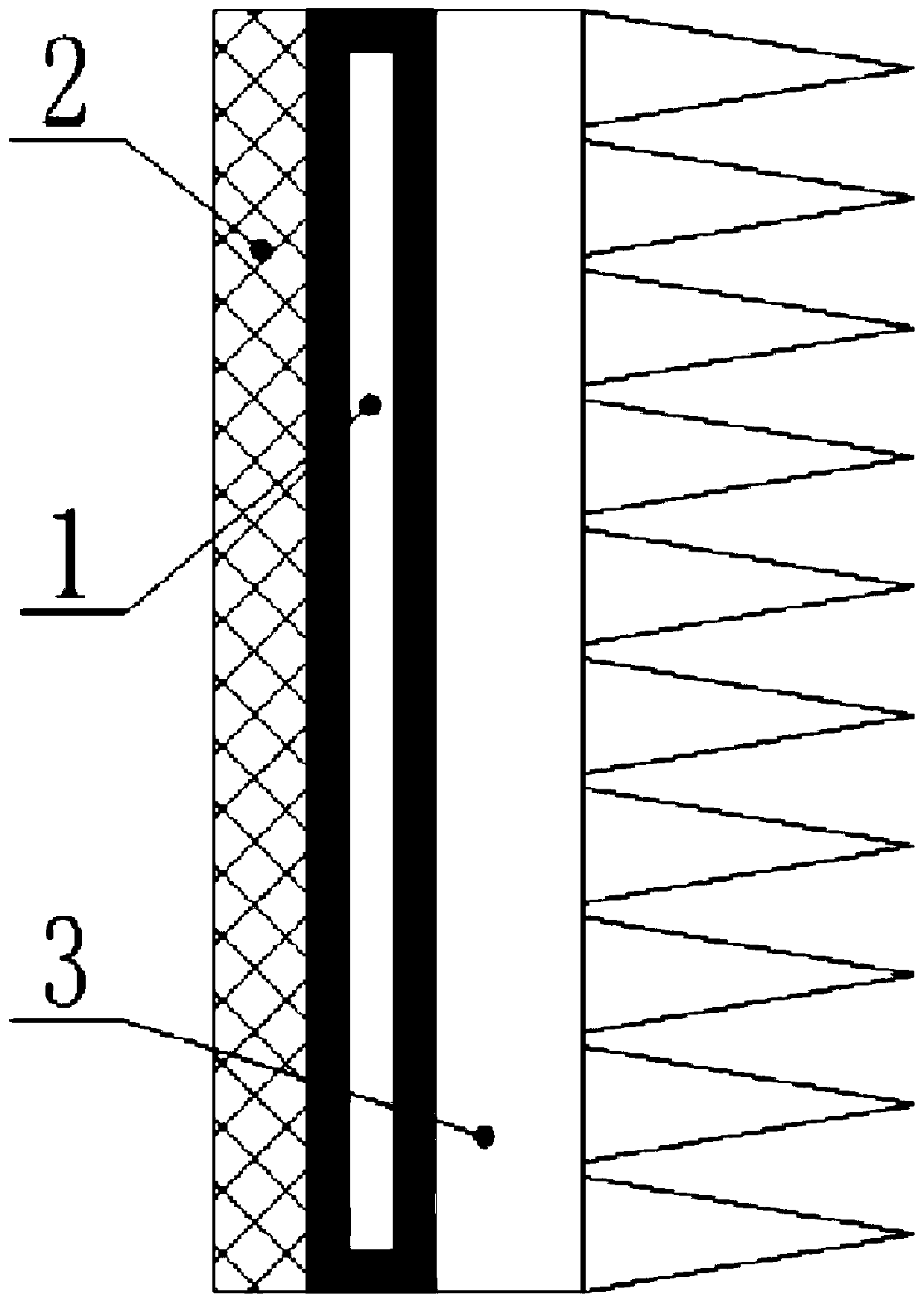

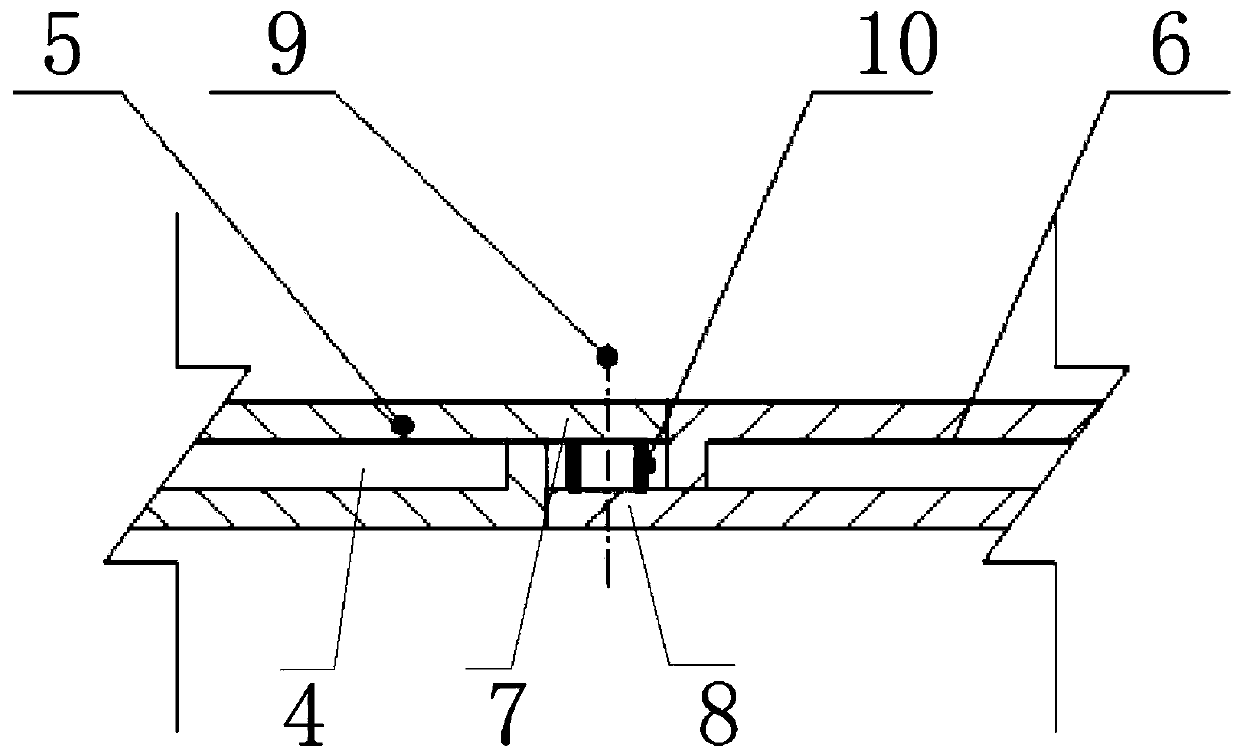

[0021] according to figure 1 , 2 As shown, this embodiment provides a sound baffle composite structure for underwater detection equipment, including a sound baffle main body, the sound baffle main body includes a cavity steel plate 1, a damping layer 2 and a sound-absorbing layer 3, The cavity steel plate 1 is the main support structure, the sound-absorbing layer 3 and the damping layer 2 are pasted on both sides of the cavity steel plate 1 by glue, and the cavity steel plate 1 is passed through the cavity steel plate unit. The hollow steel plate unit is formed by welding the facade, the flange surface and the bottom plate. The hollow steel plate unit is provided with a cavity 4, and the thickness of the cavity 4 is 10mm. The damping layer 2 is polyurethane hydroacoustic Damping material, the sound-absorbing layer 3 is a wedge structure.

[0022] The cavity steel plate unit comprises a first cavity steel plate unit 5 and a second cavity steel plate unit 6, and the facade, fl...

Embodiment 2

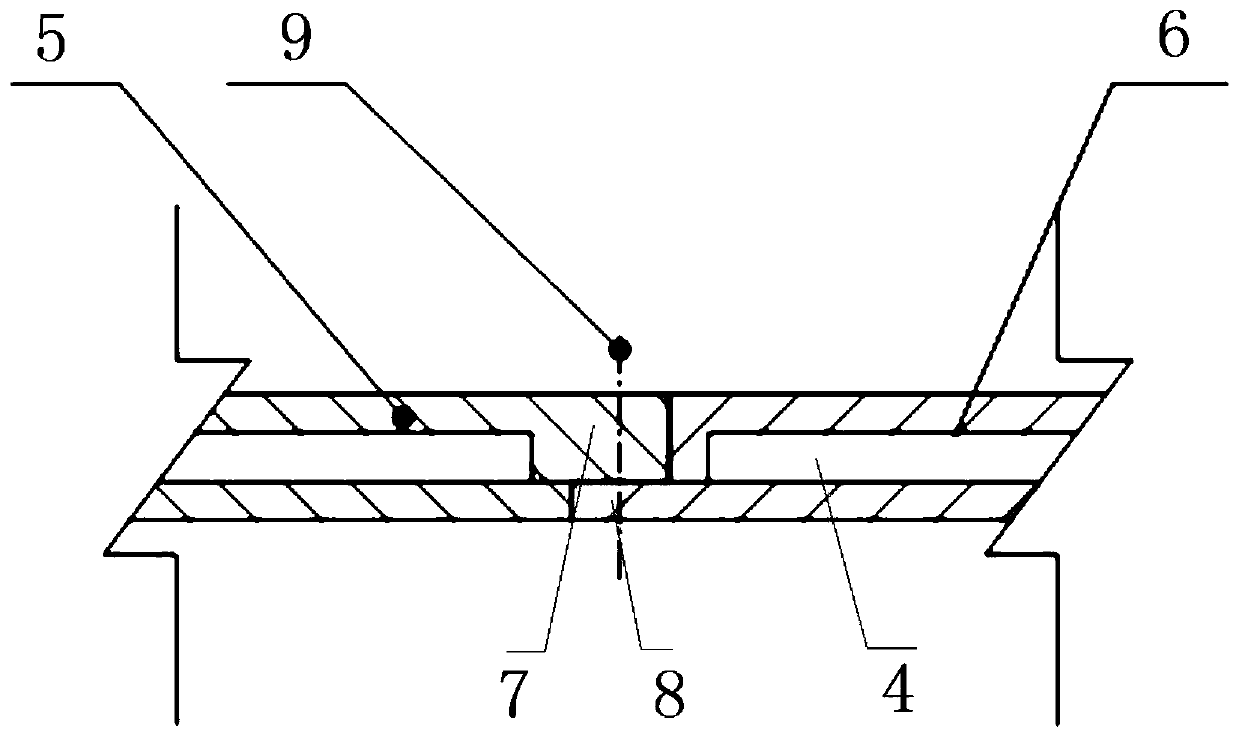

[0026] according to figure 1 , 3 As shown, this embodiment provides a sound baffle composite structure for underwater detection equipment, including a sound baffle main body, the sound baffle main body includes a cavity steel plate 1, a damping layer 2 and a sound-absorbing layer 3, The cavity steel plate 1 is the main support structure, the sound-absorbing layer 3 and the damping layer 2 are pasted on both sides of the cavity steel plate 1 by glue, and the cavity steel plate 1 is passed through the cavity steel plate unit. The hollow steel plate unit is formed by welding the facade, the flange surface and the bottom plate. The hollow steel plate unit is provided with a cavity 4, and the thickness of the cavity 4 is 10mm. The damping layer 2 is polyurethane hydroacoustic Damping material, the sound-absorbing layer 3 is a wedge structure.

[0027] The cavity steel plate unit includes a first cavity steel plate unit 5 and a second cavity steel plate unit 6, the first cavity st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com