Full-automatic precise assembling equipment for keyboard keycap

An assembly equipment and fully automatic technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of low installation and positioning accuracy, low production yield, keycap damage, etc., achieve high automatic assembly efficiency, improve yield, The effect of increasing the replacement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

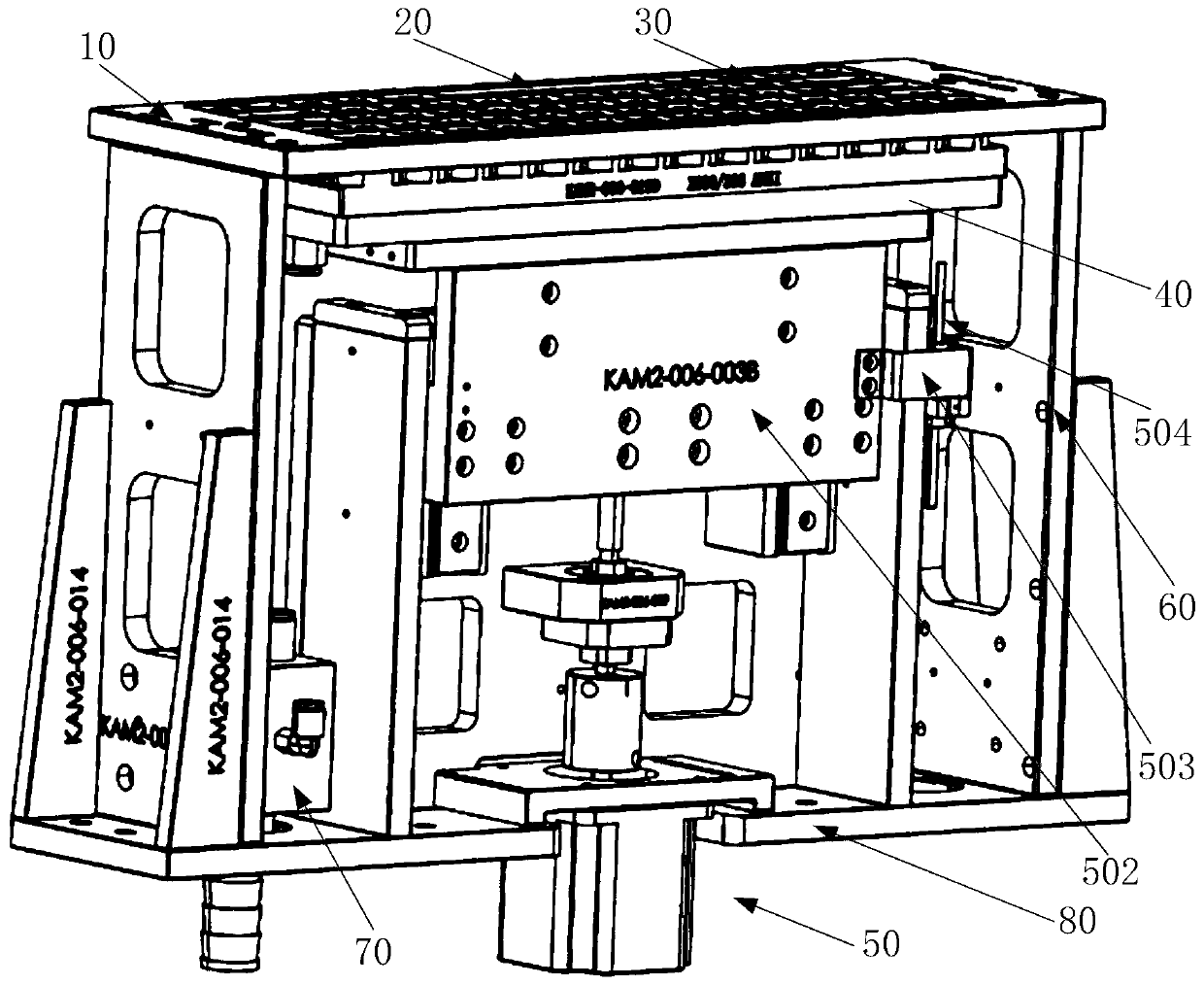

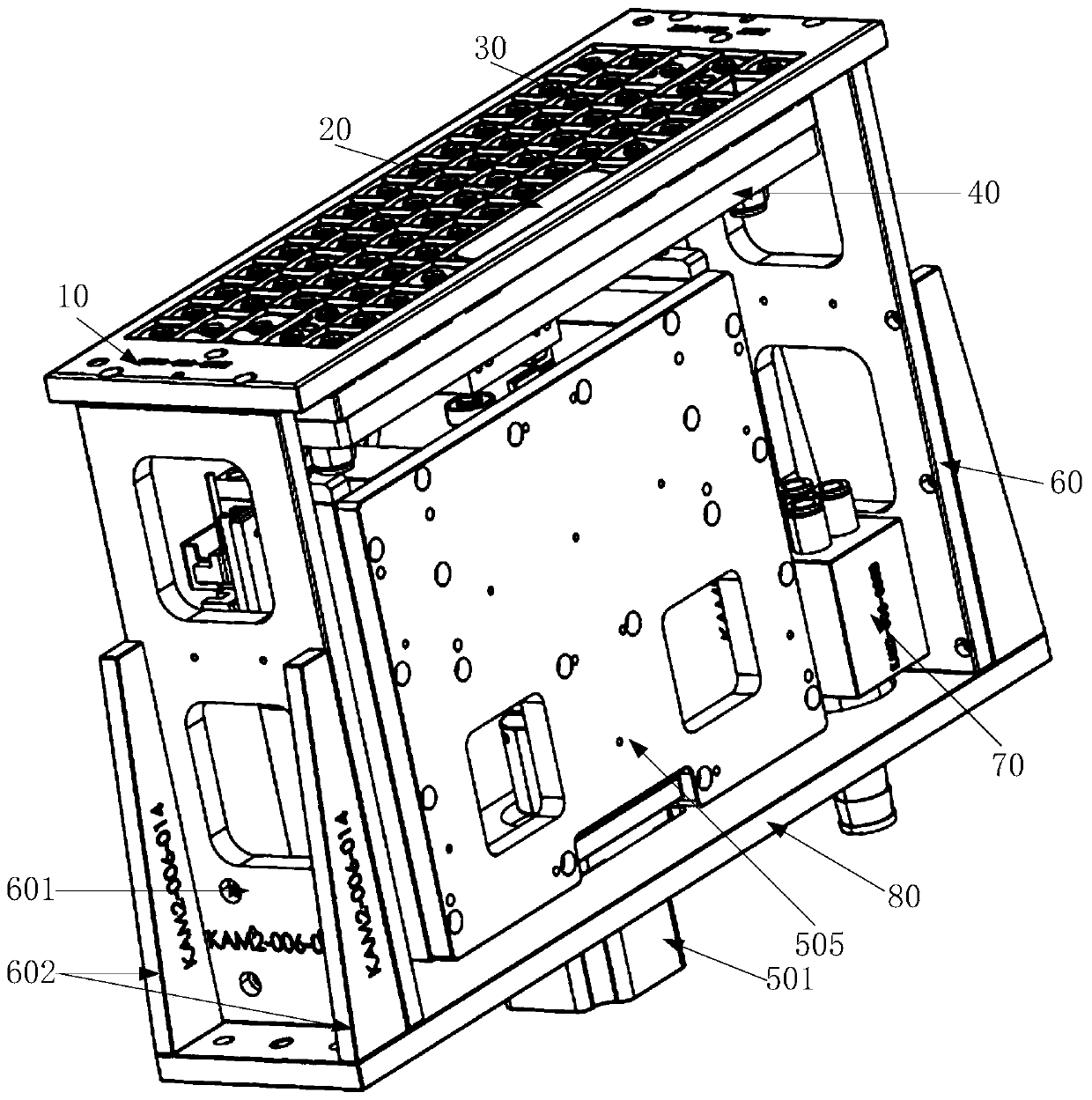

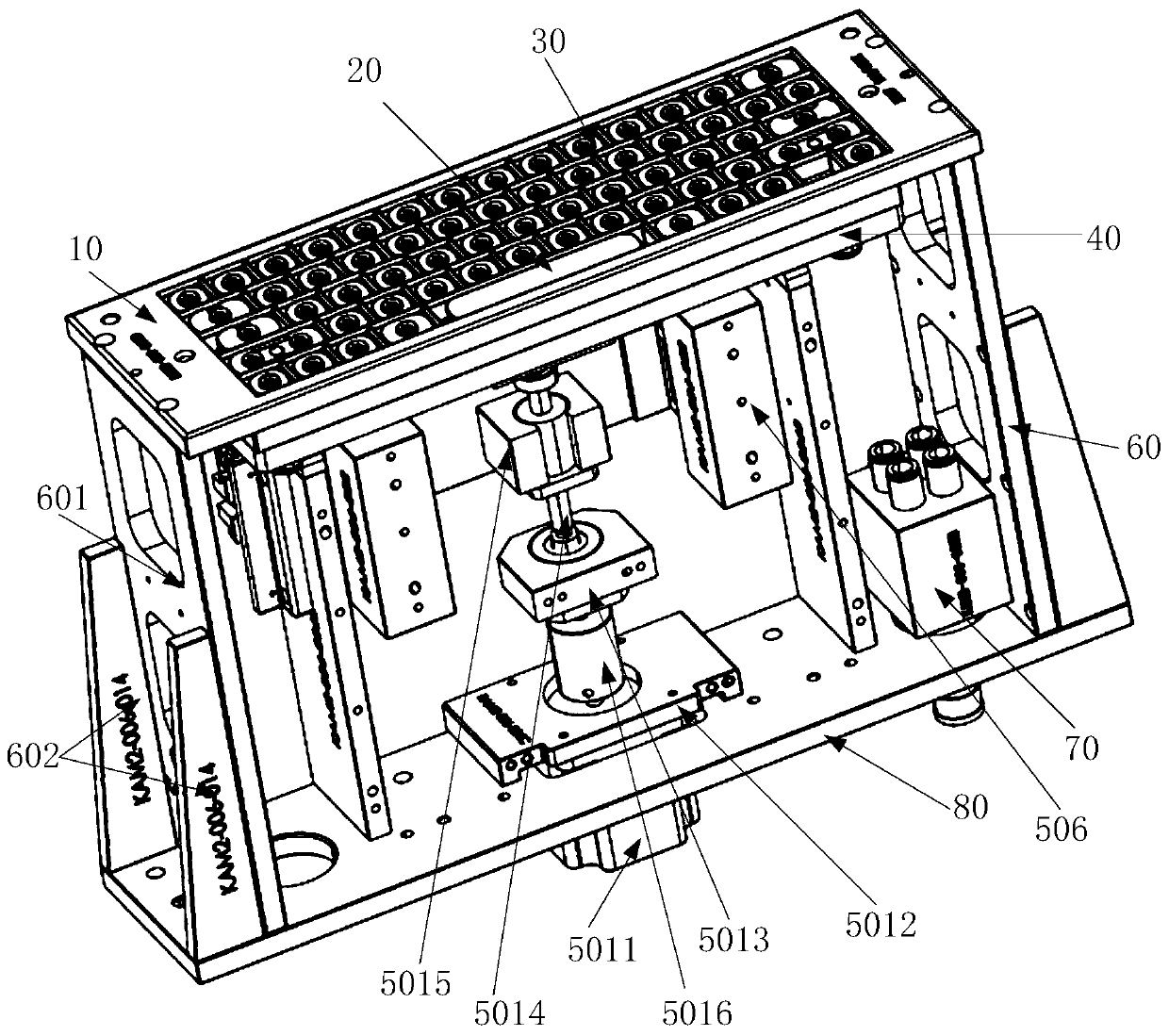

[0021] figure 1 It shows the fully automatic precision assembly equipment for keyboard keycaps provided by the present invention, the fully automatic precision assembly equipment includes a frame, a mobile single-axis mechanism, a keycap loading and unloading mechanism, a visual inspection mechanism, a keycap suction and transportation mechanism, a keycap Cap protective film collection box, keycap positioning mechanism, keycap assembly pressure head mechanism, assembly platform components, PCB feeding conveyor mechanism, PCB scanning gun rack, PCB suction and handling mechanism, industrial control system, electrical control system and air circuit , the frame is divided into top, middle and bottom, the industrial control system, electrical control system and gas circuit are respectively arranged at the bottom of the frame, the moving uniaxial mechanism is arranged at the top of the frame, and the machine In the middle of the frame, the loading and unloading mechanism, visual in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com