Automobile control accessory assembling production line

A technology for automobile control and control accessories, applied in the direction of assembly machine, comprehensive factory control, manufacturing tools, etc., can solve problems such as automatic assembly of control accessories that are not realized, achieve continuous supply and automatic assembly, reasonable and compact layout, and meet continuous sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

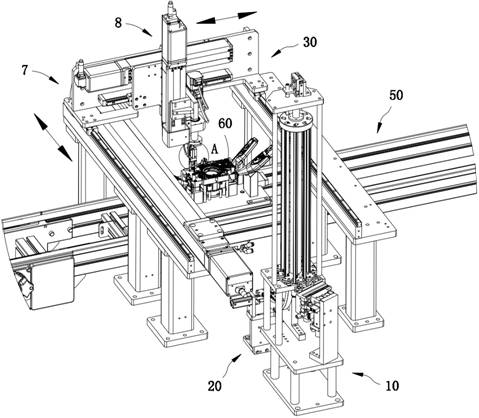

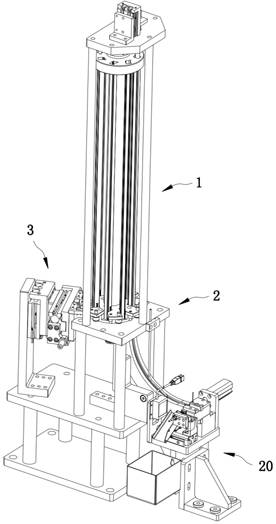

[0050] like figure 1 As shown, the automobile control parts assembly production line includes: a continuous feeding module 10, the continuous feeding module 10 is configured as a rotary multi-material tube structure, and according to the feeding progress, the continuous feeding module 10 rotates step by step, so that the Each feeding pipe works in sequence for continuous feeding; a transition feeding module 20, the transition feeding module 20 is docked with the discharge end of the transition feeding module 20; and a feeding module 30, the feeding module 30 is connected to the The transitional feeding module 20 is arranged in coordination; the control accessories 40 are continuously output and supplied by the continuous feeding module 10 , and are received and inspected by the transitional feeding module 20 one by one, and then transferred and assembled by the feeding module 30 .

[0051] Preferably, as figure 1 As shown, it also includes: an assembly conveying line 50 , the...

Embodiment 2

[0065] The same or corresponding components in this embodiment and the above-mentioned embodiments are marked with corresponding reference numerals as in the above-mentioned embodiments. For the sake of simplicity, only the points of difference from the above-mentioned embodiments will be described below. The difference between this embodiment and the above-mentioned embodiment is:

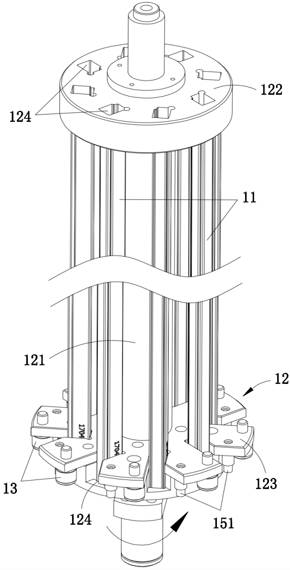

[0066] Preferably, as Figure 5 As shown, the rotary feeding mechanism 1 further includes: an auxiliary positioning structure 14, the auxiliary positioning structure 14 is cooperatively arranged between the bottom of the rotary feeding frame 12 and the feeding frame 2, which is assisted by a fixed-point engaging action The rotating material rack 12 is rotated in place step by step.

[0067] Preferably, as Figure 13 As shown, the auxiliary positioning structure 14 includes: elastic ball structures 141 arranged in a circular array at the bottom of the rotating material rack 12, and a plurality of...

Embodiment 3

[0072] The same or corresponding components in this embodiment and the above-mentioned embodiments are marked with corresponding reference numerals as in the above-mentioned embodiments. For the sake of brevity, only the points of difference from the above-mentioned embodiments are described below. The difference between this embodiment and the above-mentioned embodiment is:

[0073] Preferably, as Figure 8 As shown, the transition feeding module 20 includes: a feeding mechanism 5, such as Figure 9-10 As shown, the material receiving mechanism 5 includes: a material receiving seat 51, and the material receiving seat 51 is slidably arranged on the feeding frame 52 so as to be connected to or staggered from the discharge end of the continuous feeding module 10; and the clamping drive part 53, the material receiving seat 51 is connected with the translation driving end of the clamping driving part 53, after the receiving seat 51 is connected to a control accessory 40, the clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com