Device used for production of solar water heaters

A technology of solar water heaters and equipment, applied in heat exchange equipment, metal processing equipment, feeding devices, etc., can solve the problems of inability to realize automation, great safety hazards, low stamping efficiency, etc., achieve automation, reduce manpower and material resources, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

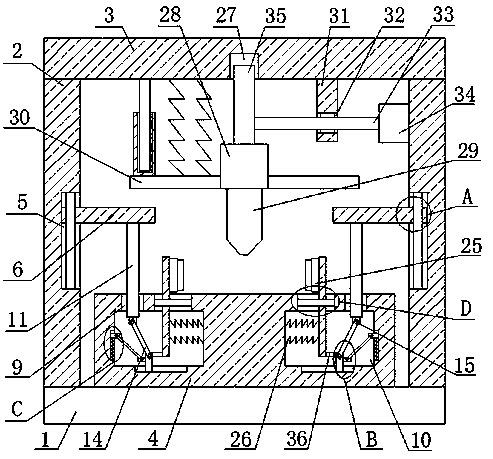

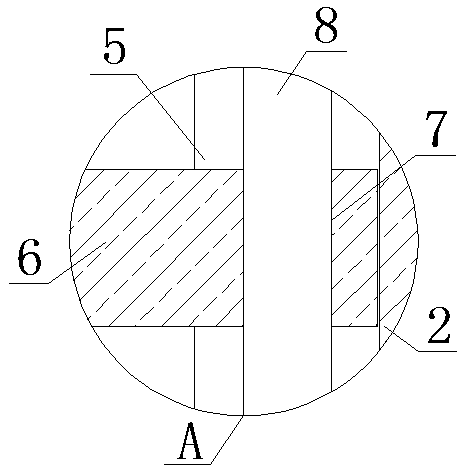

[0028] refer to Figure 1-5 , a kind of solar water heater production equipment, comprising a fixed base 1, fixed columns 2 are fixedly installed on both sides of the top of the fixed base 1, the top of the two fixed columns 2 is fixedly installed with the same fixed plate 3, the top of the fixed base 1 A placement platform 4 between the two fixed columns 2 is fixedly installed, and the sides of the two fixed columns 2 close to each other are provided with a moving groove 5, and a moving plate 6 is slidably installed in the two moving grooves 5, and the two moving A limit hole 7 is provided on the plate 6, and a limit rod 8 is slidably installed in the two limit holes 7, and the top and bottom ends of the limit rod 8 are respectively fixed to the top inner wall and the bottom inner wall of the corresponding moving groove 5. connect.

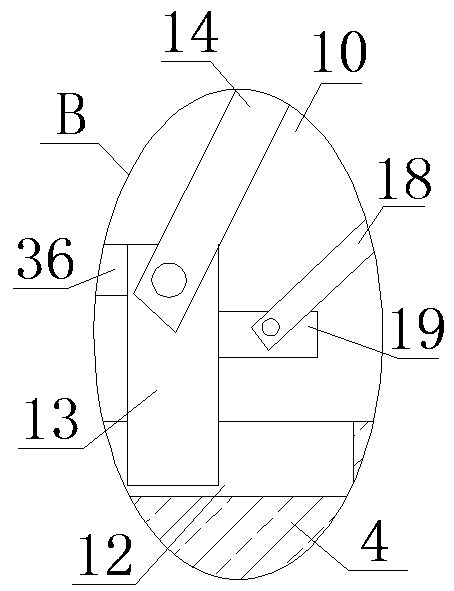

[0029] In the present invention, two sliding holes 9 are provided on the top of the placing table 4, installation grooves 10 are provided on th...

Embodiment 2

[0039] refer to Figure 1-5 , a kind of equipment for producing solar water heaters, comprising a fixed base 1, both sides of the top of the fixed base 1 are fixedly connected with fixed columns 2 by bolts, and the tops of the two fixed columns 2 are fixedly connected with the same fixed plate 3 by bolts, fixed The top of the seat 1 is fixedly connected with a placement platform 4 between the two fixed columns 2, and the sides of the two fixed columns 2 close to each other are provided with a moving slot 5, and a moving slot 5 is slidably installed in the two moving slots 5. plate 6, two moving plates 6 are provided with limit holes 7, and limit rods 8 are slidably installed in the two limit holes 7, and the top and bottom ends of the limit rods 8 are respectively connected to the corresponding moving slots 5. The top inner wall and the bottom inner wall are fixedly connected, and the limit rod 8 limits the position of the moving plate 6 .

[0040] In the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com