Automatic assembling equipment and assembling method of automobile wire harness connector

A technology for automatic assembly and automotive wiring harnesses, applied in assembly machines, metal processing equipment, metal processing, etc., can solve the problems of low degree of automation and low efficiency, and achieve the effect of compact equipment structure, high efficiency and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

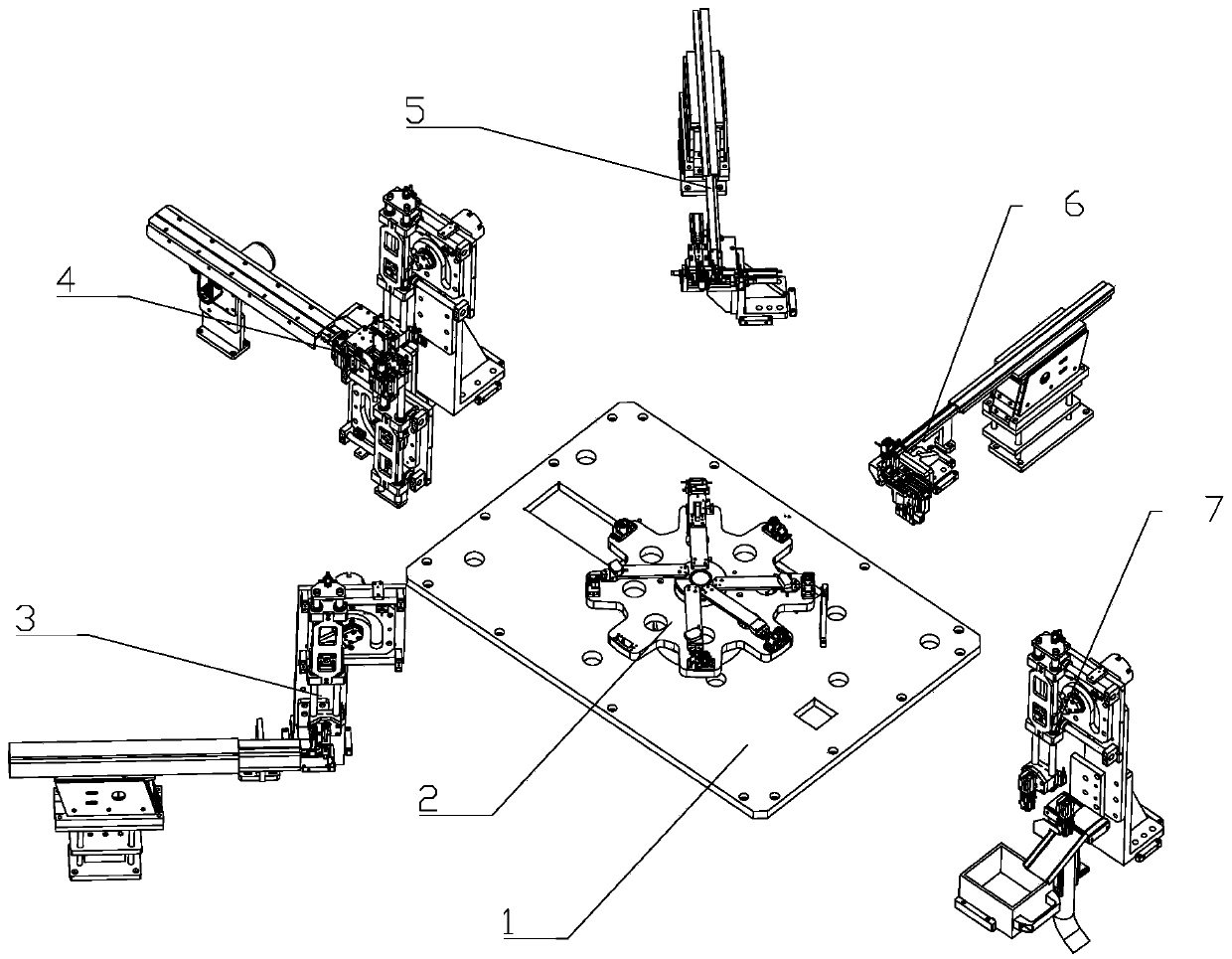

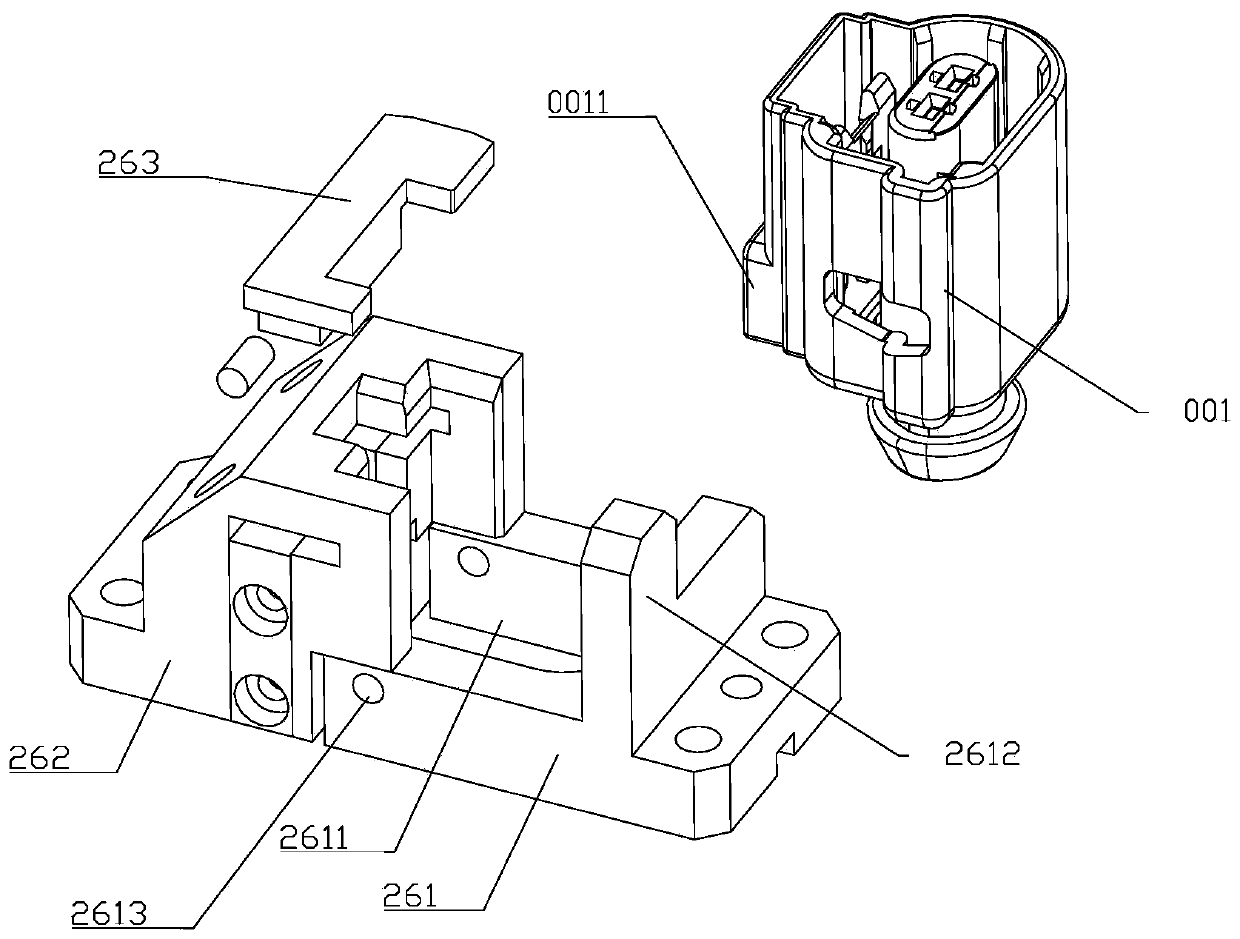

[0031] like figure 1 As shown, an automatic assembly equipment for automotive wiring harness connectors includes a frame 1 and a transfer device 2 installed on the frame 1, a shell feeding device 3, a sealing ring assembly device 4, a holding block assembly device 5, and a positioning buckle Assembly device 6 and unloading device 7; transfer device 2 is arranged in the middle of frame 1, shell feeding device 3, sealing ring assembly device 4, holding block assembly device 5, positioning buckle assembly device 6 and unloading device 7 Radially arranged around the transfer device 2, along the processing direction, the shell feeding device 3, the sealing ring assembly device 4, the holding block assembly device 5, the positioning buckle assembly device 6 and the unloading device 7 are arranged in sequence.

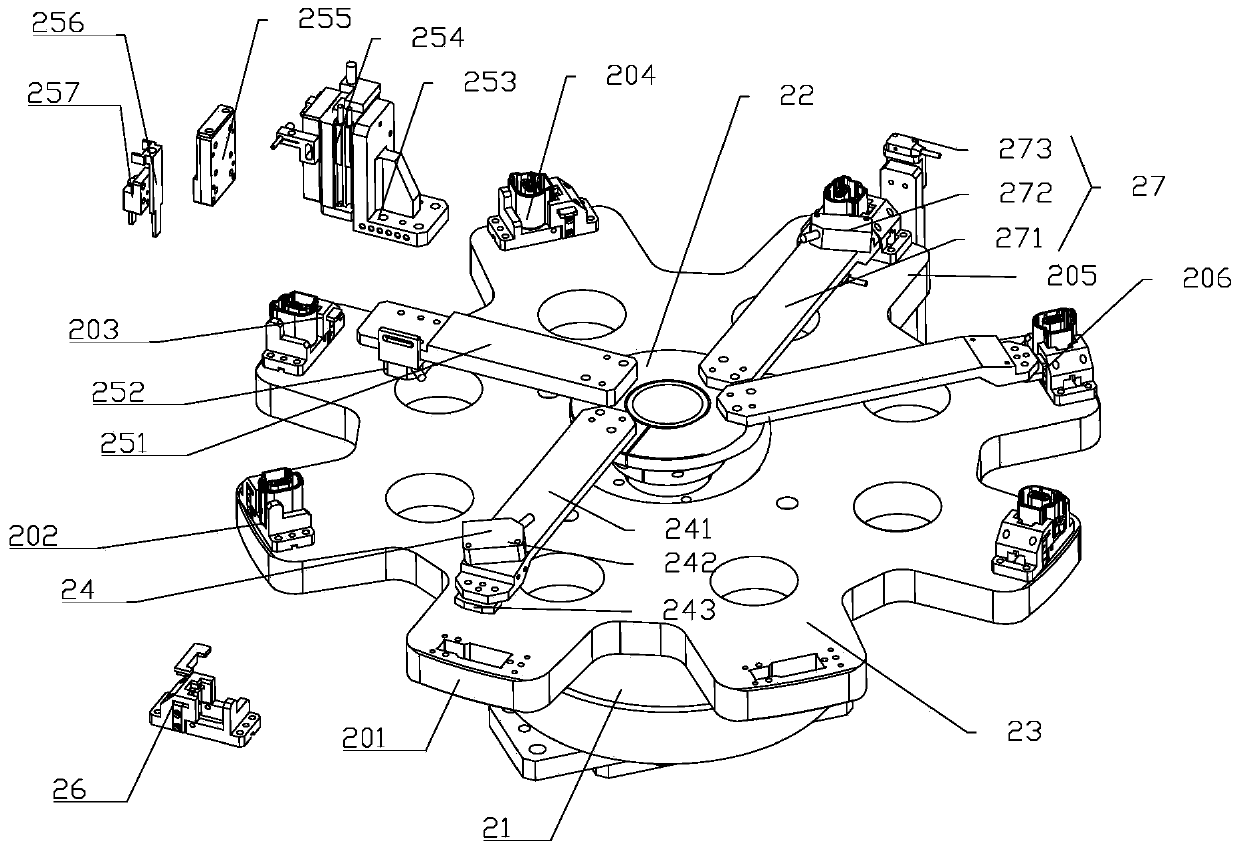

[0032] The transfer device 2 is provided with evenly distributed jigs, which are used to locate and transfer the automotive wiring harness connectors, and reach the designate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com