Clamp device matched with automatic clamp changing intelligent robot for use and application method of clamp device matched with automatic clamp changing intelligent robot for use

A technology of intelligent robot and fixture device, which is applied in the field of intelligent robot, can solve the problems of unavailable production, high cost, and many moving parts, and achieve the effects of facilitating suction work, increasing separation speed, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

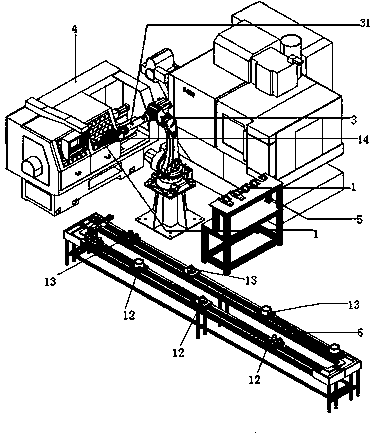

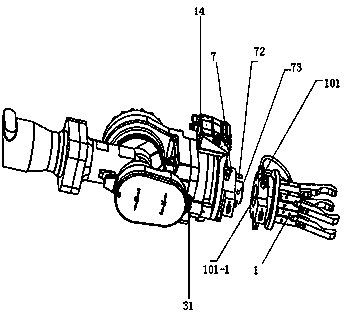

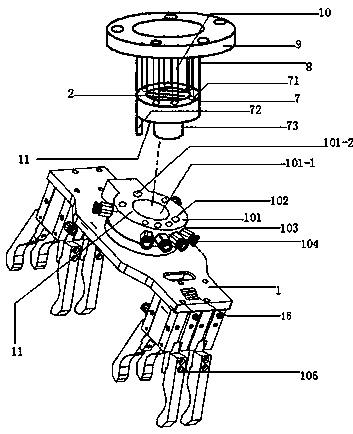

[0019] figure 1 , 2 , shown in 3, a fixture device used in conjunction with an automatic fixture-changing intelligent robot, including a fixture body 1 of various shapes, an annular electromagnet 2, an industrial barcode scanner 14, a power input terminal of the annular electromagnet 2 and an intelligent The output end of the control circuit board power supply of the robot body 3 is connected through wires, the signal output end of the industrial barcode scanner 14 and the signal input end of the control circuit board are connected through wires, and the industrial barcode scanner 14 is installed on the front end of the robot arm 31 of the robot body through a screw nut In the upper part, various types of barcodes 15 are bonded to fixture bodies 1 with different shapes. The intelligent robot 3 is located in the middle of the ground in the processing area. front end on the line 6), the finished workpiece 13 placement area (the processed workpiece 13 is located at the upper rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com