A tile opening device for building construction

A technology for building construction and ceramic tiles, which is applied in the field of ceramic tile opening devices for building construction, can solve the problems of not very flat, low safety factor, inconvenient cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

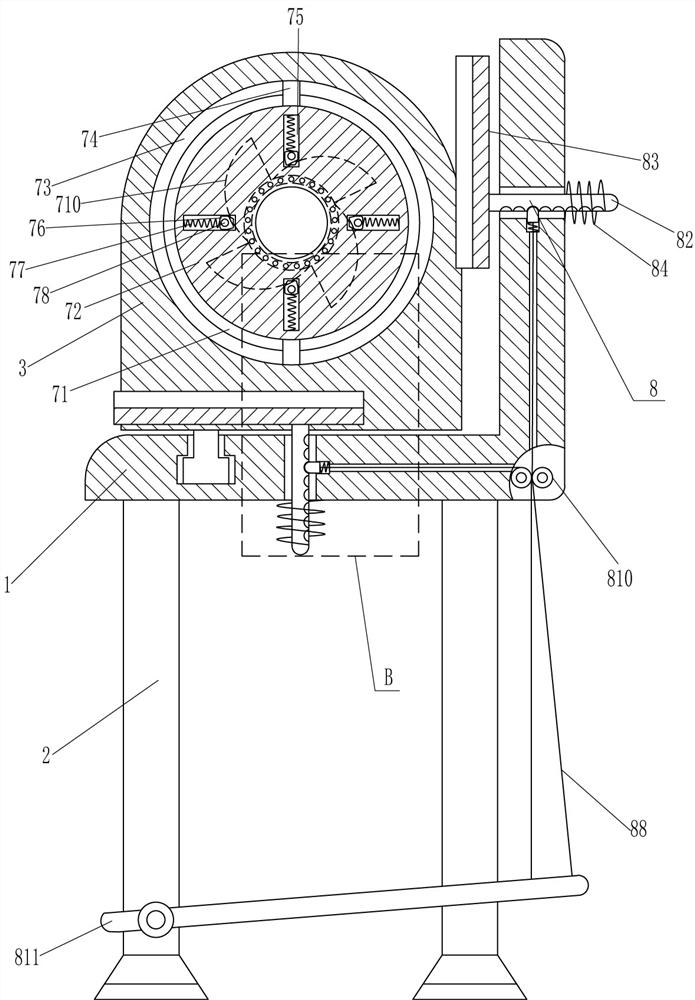

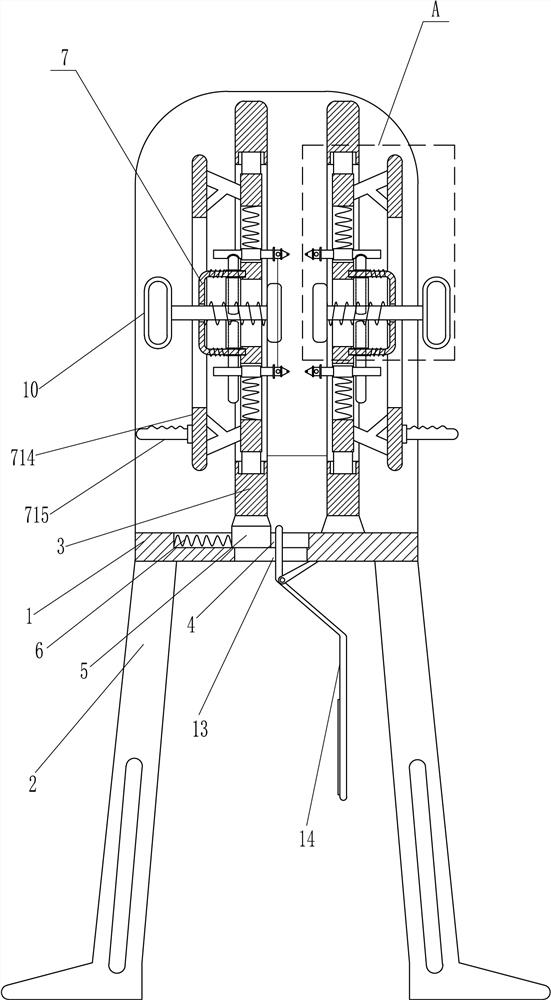

[0020] A tile opening device for building construction, such as Figure 1-3 As shown, it includes an L-shaped plate 1, legs 2, a vertical plate 3, a first slider 5, a first spring 6 and a ring cutting device 7, and four legs 2 are installed at the bottom of the L-shaped plate 1, and the L-shaped plate 1. A vertical plate 3 is installed on the right side of the inner bottom. A first chute 4 is opened on the left side of the inner bottom of the L-shaped plate 1. The first chute 4 is slidingly provided with a first slider 5. The inner left side of the first chute 4 is A first spring 6 is connected between the wall and the left side of the first slide block 5, and a riser 3 is installed on the top of the first slide block 5, and a ring cutting device 7 is provided in the middle of the two riser blocks 3, wherein the ring cut The device 7 is used for engraving the tiles, and the circular cutting device 7 rotates along a predetermined track to engrave the tiles.

[0021] The circum...

Embodiment 2

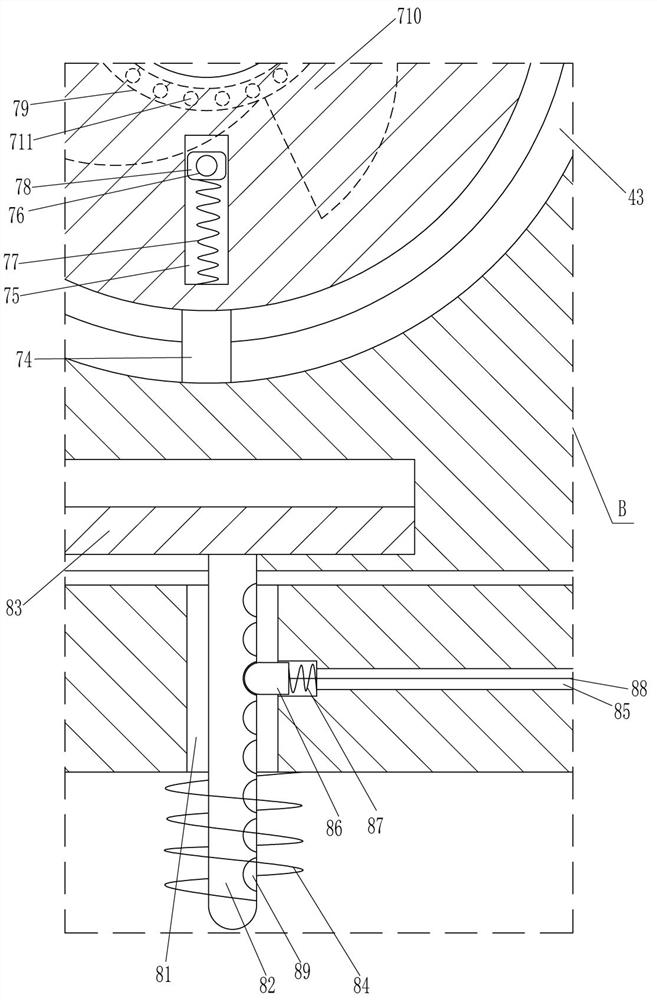

[0025] On the basis of Example 1, such as figure 2 and Figure 4As shown, an adjustment device 8 is also included, and the adjustment device 8 includes a connecting rod 82, a placement plate 83, a fourth spring 84, a block 86, a fifth spring 87, a pull wire 88, a fixed pulley 810 and a pedal 811, an L-shaped plate 1 and the rear of the L-shaped plate 1 are provided with a second through hole 81, the second through hole 81 is slidingly provided with a connecting rod 82, and the top of the connecting rod 82 at the bottom of the L-shaped plate 1 is equipped with a placement plate 83 , the front end of the connecting rod 82 at the rear of the L-shaped plate 1 is equipped with a placement plate 83, the fourth spring 84 is connected between the connecting rod 82 and the outside of the L-shaped plate 1, and the right side of the second through hole 81 at the bottom of the L-shaped plate 1 There is a third through hole 85 on the side, and there is also a third through hole 85 below ...

Embodiment 3

[0028] On the basis of Example 1 and Example 2, as figure 1 and image 3 As shown, it also includes a handle 10, a rubber block 11 and a sixth spring 12. The middle parts of the two disks 72 are provided with a fourth through hole 9, and the fourth through hole 9 is slidingly provided with a handle 10. The outer end of the handle 10 is Through the N-shaped rod 712, a rubber block 11 is installed at the inner end of the handle 10, the rubber block 11 is located between the two vertical plates 3, and the sixth spring 12 is connected between the rubber block 11 outside and the N-shaped rod 712.

[0029] It also includes a special-shaped rod 14, and the bottom of the L-shaped plate 1 has a word hole 13, which communicates with the first chute 4. The rear side is hingedly connected, and the top of the special-shaped rod 14 is in contact with the right side of the first slide block 5 .

[0030] When the tile circle is completed, the operator pulls the handle 10 to move outward, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com