Automobile Suspension System and Road Surface Roughness Measurement Method Based on Visual Sensing Technology

A technology of automobile suspension and visual sensing, which is applied in the direction of suspension, elastic suspension, measuring device, etc., and can solve safety problems and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

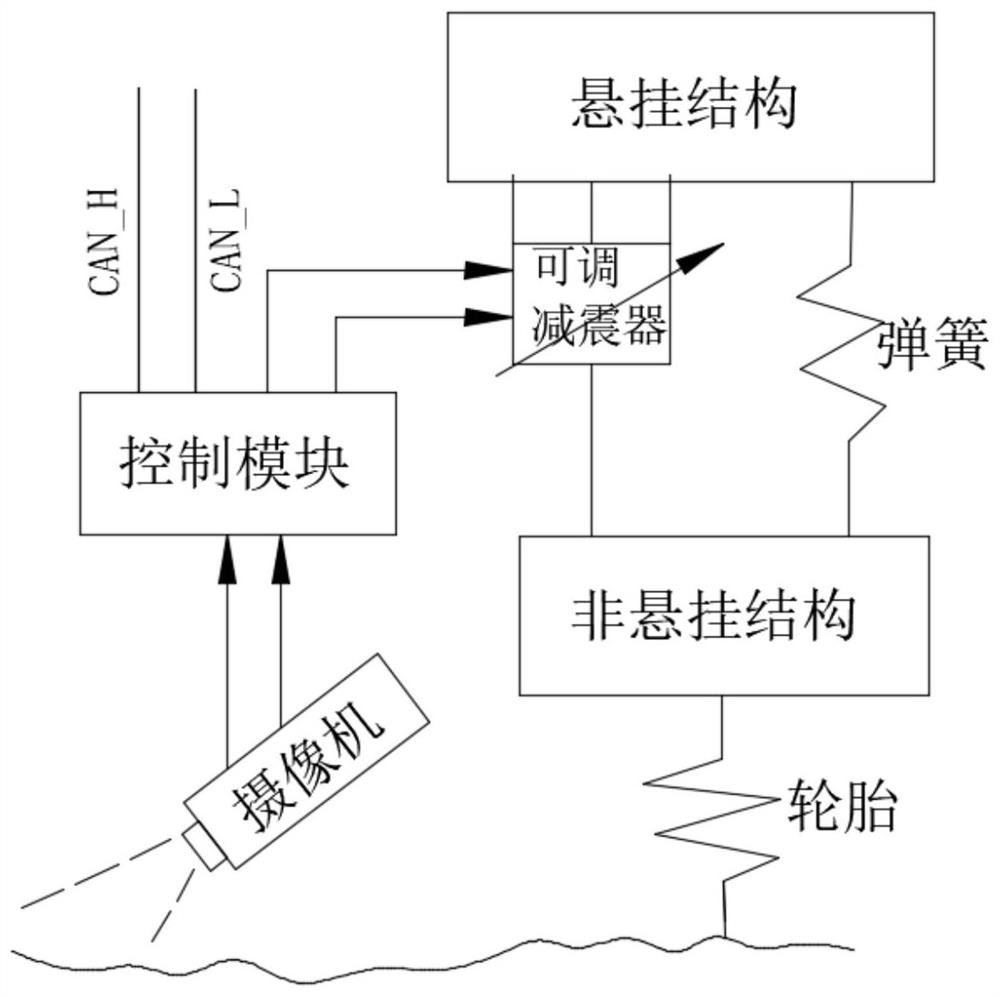

[0051] Such as figure 1 As shown, a kind of automobile suspension system based on visual sensing technology in this embodiment includes a non-suspension structure, the suspension structure is installed on its top through springs and adjustable shock absorbers, and the bottom of the non-suspension structure is a tire structure; it also includes a camera , which is electrically connected to the control module, the control module is connected to the CAN bus and the damping control module, and the damping control module includes a control motor and a motor amplifier.

[0052] The adjustable shock absorber is a hydraulic shock absorber, and the control motor controls the action of the oil outlet inside the hydraulic shock absorber; the control module adopts a fuzzy controller.

[0053] Design principle of the present invention:

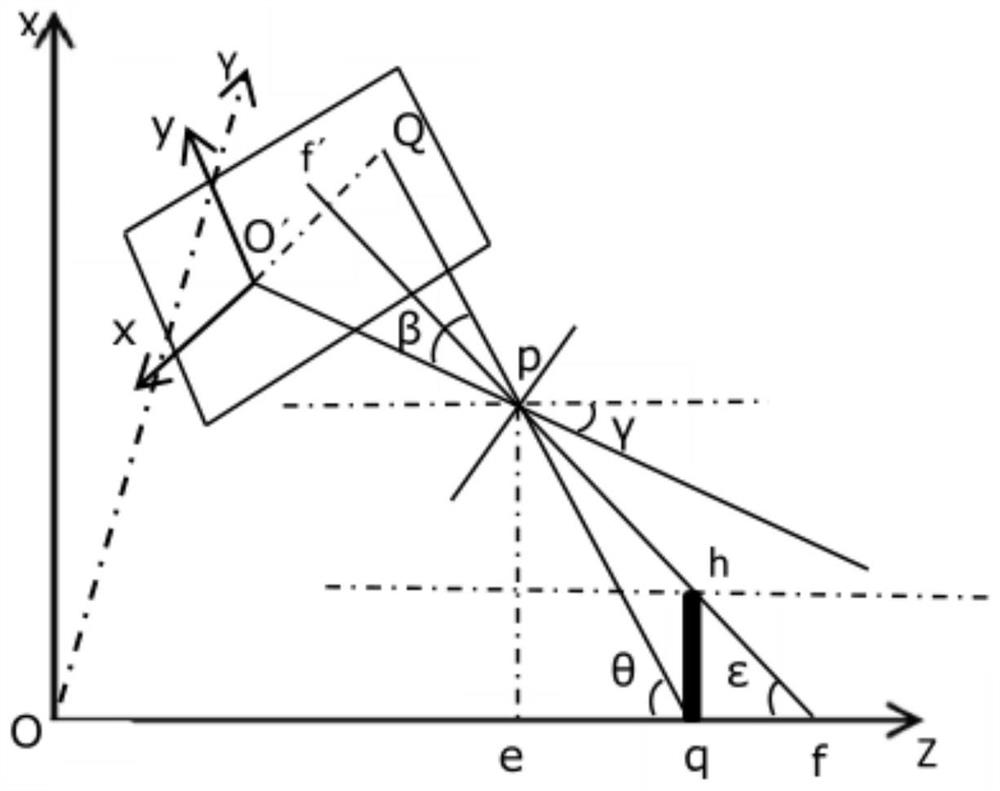

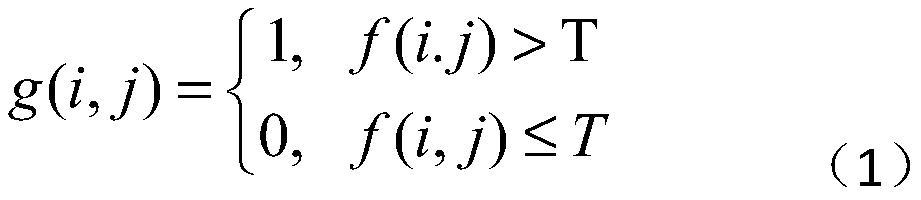

[0054] For t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com