Composite board for low-frequency broadband noise reduction of compartment structure

A composite board and low-frequency technology, applied in the field of composite boards, can solve the problems of narrow sound absorption frequency band, passenger noise pollution, passenger comfort, etc., and achieve the effect of small structure size, widened bandwidth and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

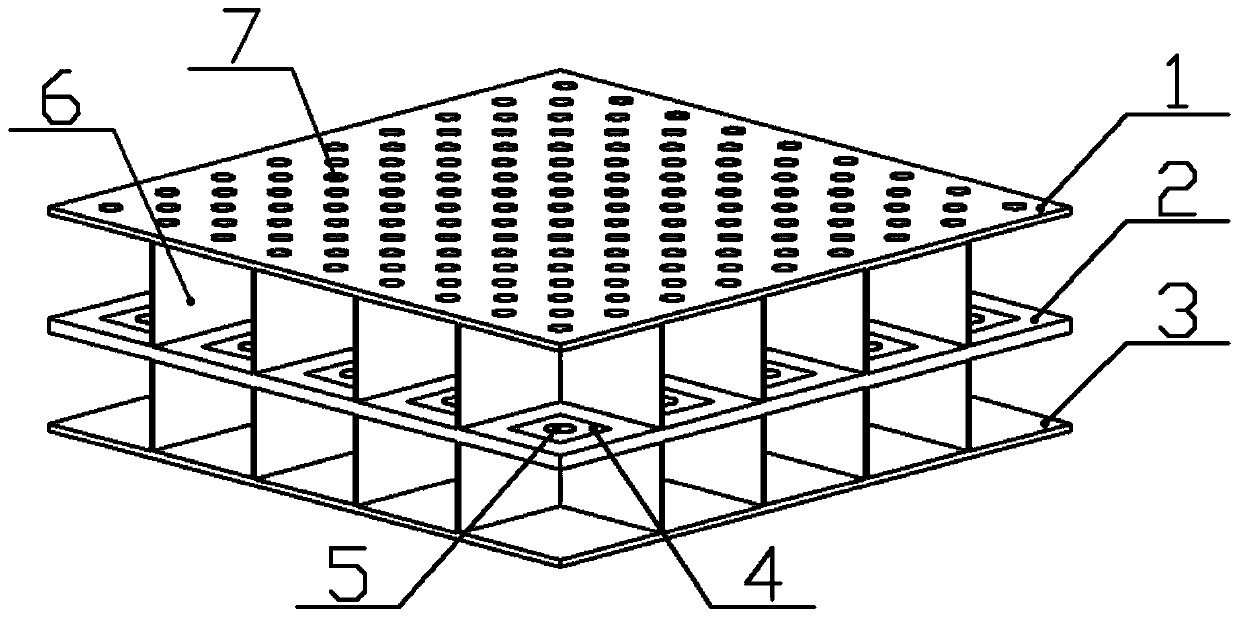

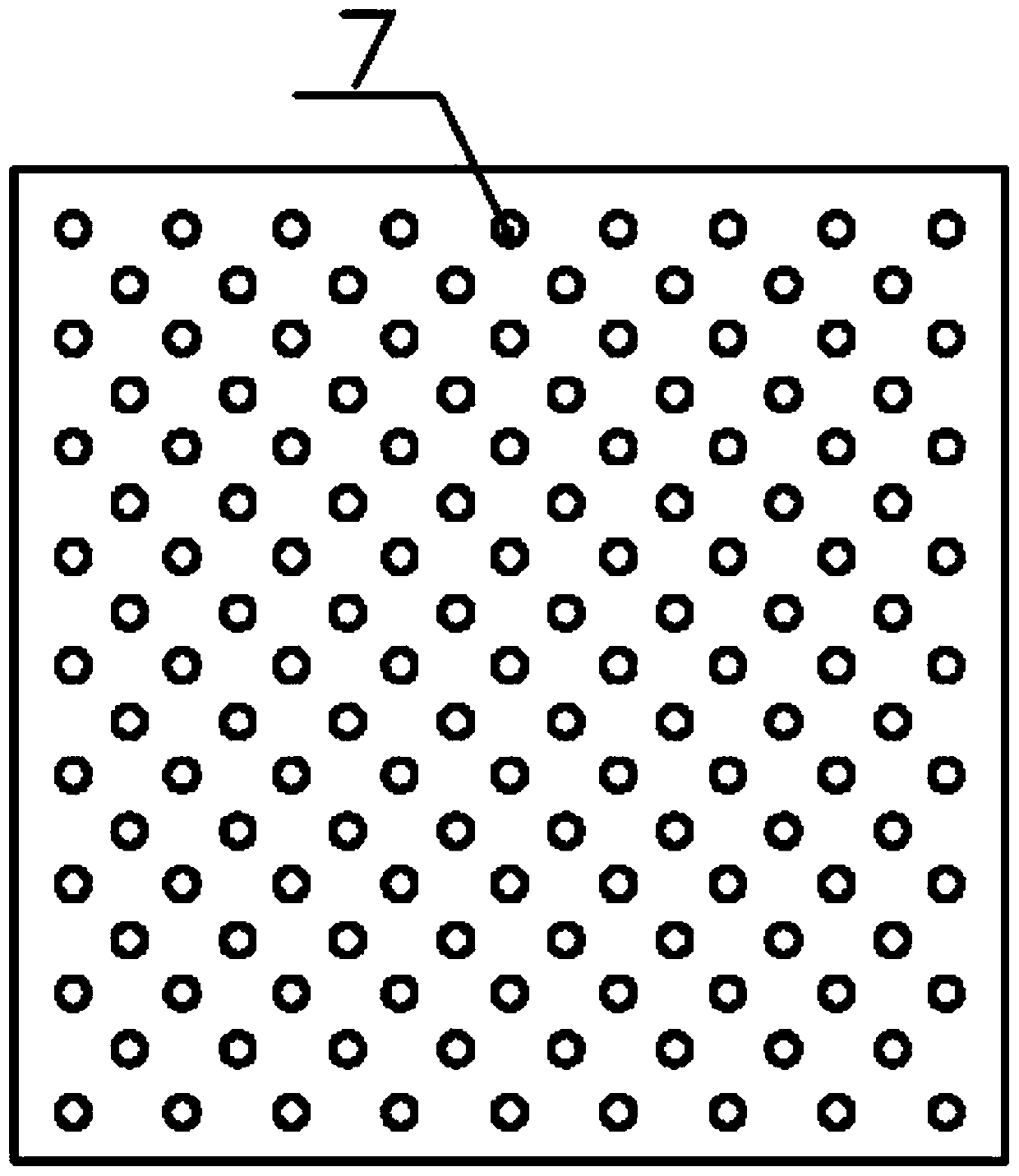

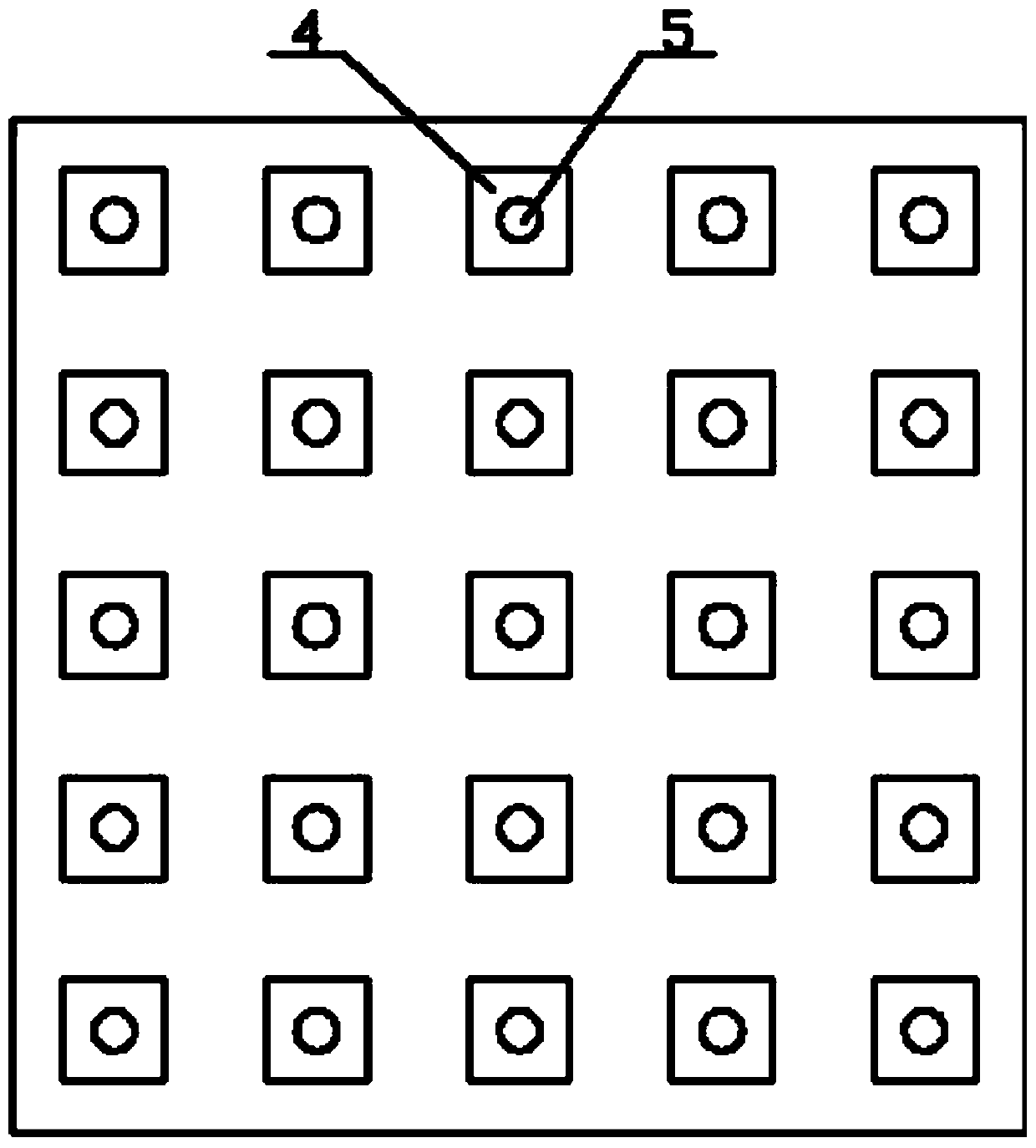

[0018] Specific implementation mode one: as Figure 1 to Figure 5 As shown, the present invention discloses a composite panel for low-frequency broadband noise reduction facing the box body structure, including a perforated panel 1, a local resonance panel, a back panel 3 and a plurality of support panels 6, and the local resonance panel includes a substrate 2 and a plurality of thin-film vibrators, the substrate 2 is made of light-weight and high-rigidity metal or non-metallic material; the perforated plate 1 is provided with a plurality of sound-transmitting holes 7, and the apertures of the sound-transmitting holes 7 and the distance between them are according to The frequency band design of the required noise reduction, the perforated plate 1, the local resonant plate and the back plate 3 are arranged side by side from the inside to the outside, and the back plate 3 is installed outside the local resonant plate for sound insulation and protection of the local resonant plate...

specific Embodiment approach 2

[0061] Specific implementation mode two: as figure 1 , 2 As shown, this embodiment is a further description of Embodiment 1, and the plurality of sound-transmitting holes 7 are uniformly arranged.

specific Embodiment approach 3

[0062] Embodiment 3: This embodiment is a further description of Embodiment 1. The thin-film vibrator is attached to the surface of the substrate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com