A rail vehicle corbel, underframe and underframe welding method

A technology for rail vehicles and corbels, which is applied to the underframe, welding equipment, welding equipment, etc., and can solve the problems of long working hours, costs, welding deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

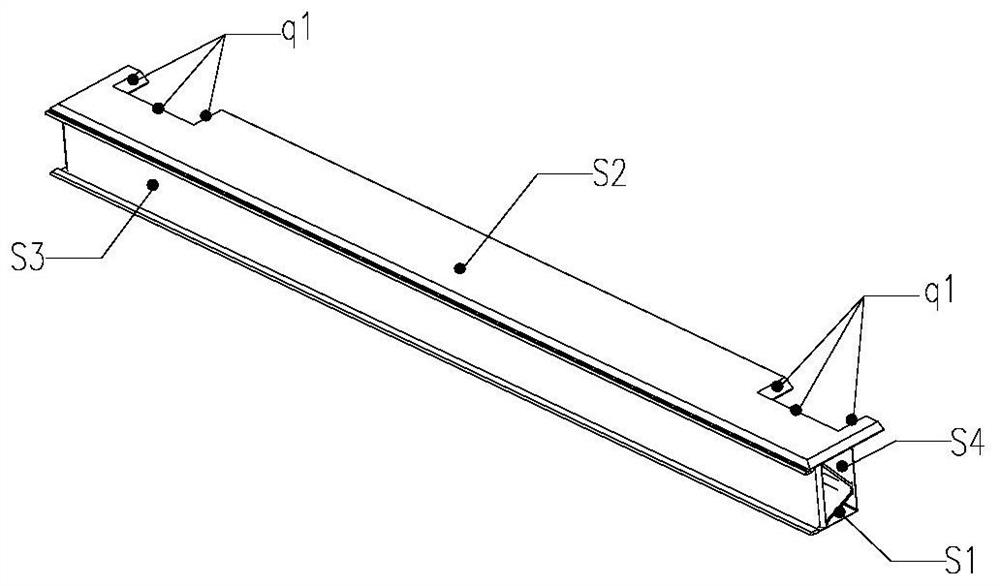

[0063] The present invention discloses a rail vehicle bolster, wherein the rail vehicle bolster comprises a bolster main body, an end cover plate 302 and a floor connecting profile 307 .

[0064] The floor connecting profiles 307 are respectively welded on the longitudinal sides of the corbel main body, and the outer side of the floor connecting profiles 307 are welded with the short floor 305 and the long floor 306 of the underframe respectively. The framed floor adopts a non-through-length floor structure, that is, the floor is disconnected at the rail vehicle bolster.

[0065] That is, the floor connecting profile is welded inward to the main body of the corbel, and outwardly welded to the underframe floor. Connect them in the order of underframe floor, floor connecting profile, and corbel main body.

[0066] The transverse ends of the top surface of the corbel main body are provided with technological gaps, and the end cover plates are blocked on the technological gaps. ...

Embodiment 2

[0072] In the second embodiment provided by the present invention, the structure of the rail vehicle bolster in this embodiment is similar to that of the rail vehicle bolster in the first embodiment, the similarities will not be repeated, and only the differences will be described.

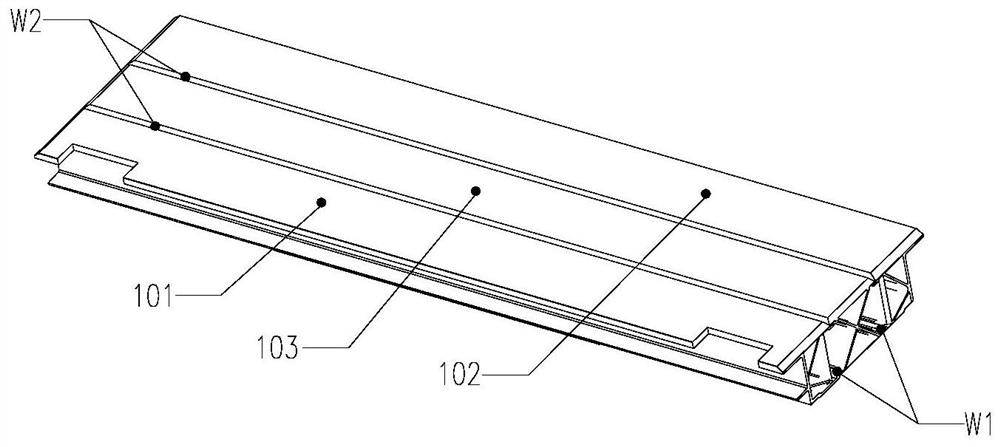

[0073] In this embodiment, the present invention discloses that the main body of the bolster includes a first side bolster 101, a second side bolster 102 and a middle bolster 103, and the first side bolster 101 and the second side bolster 102 are welded in the middle respectively. Longitudinal sides of corbel 103 .

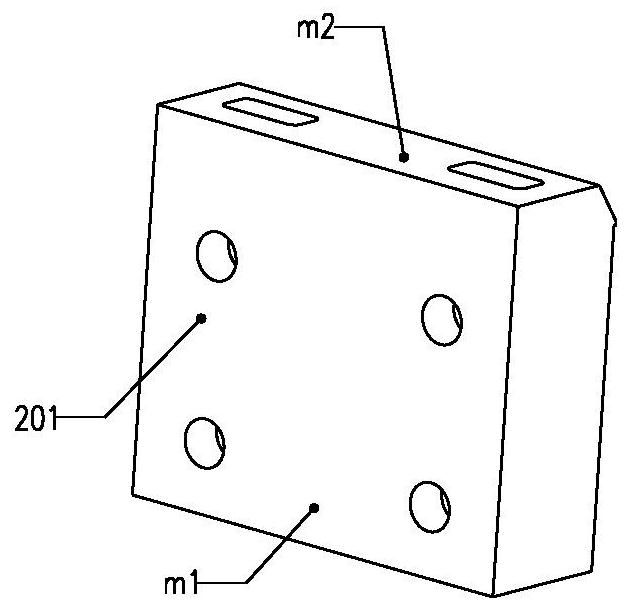

[0074] Further, the present invention discloses that the rail vehicle bolster further includes an anti-rolling structure 104 , and the anti-rolling structure 104 includes an anti-rolling mounting seat 201 and a positioning screw block 202 .

[0075] The bottom surface of the first side bolster 101 is provided with a mounting notch, the anti-rolling mounting seat 201 is welded in the m...

Embodiment 3

[0095] The present invention provides an underframe comprising a rail vehicle bolster as in any of the above embodiments.

[0096] Since the underframe disclosed in the present invention includes the rail vehicle bolster in any of the above embodiments, the beneficial effects of the above-mentioned rail vehicle bolster are all included in the underframe disclosed in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com