Air vehicle capable of achieving transformation recycling and recycling method

A technology of aircraft and flight speed, applied in the system of aerospace vehicles returning to the earth's atmosphere, landing devices of aerospace vehicles, weapon types, etc., can solve the problem of large damage to engines and drag surfaces, reduced power efficiency, and SpaceX dumping, etc. problem, to achieve the effect of low ablation, low power consumption, and simple deformation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

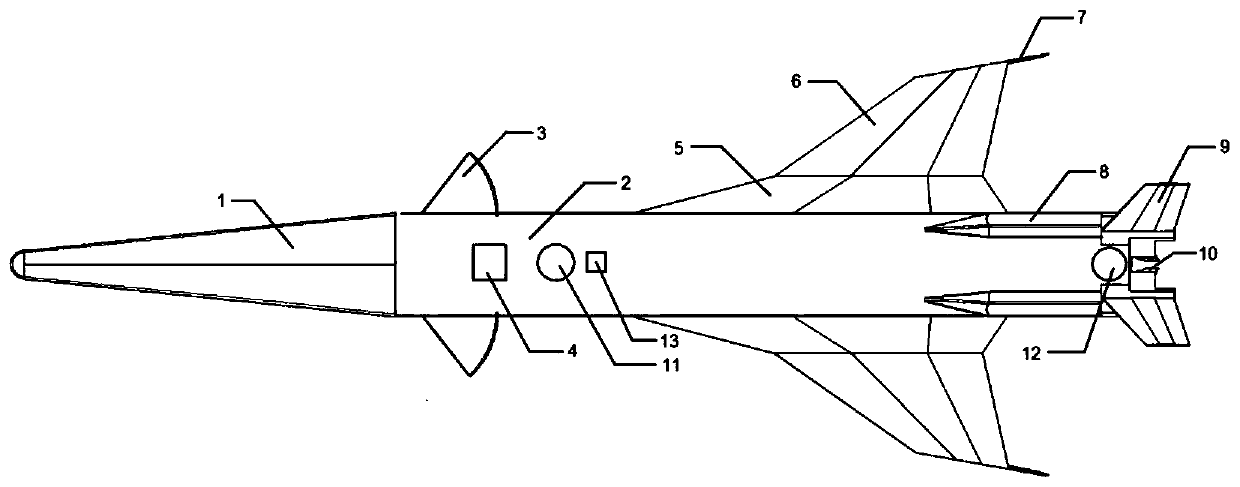

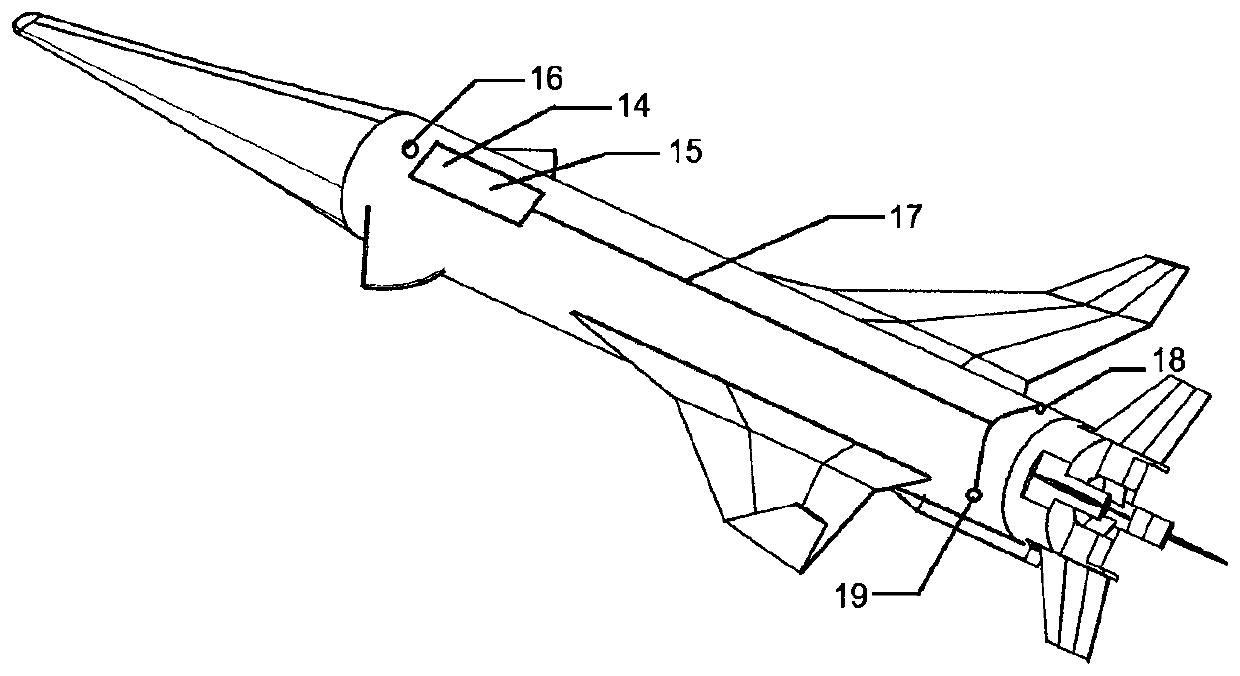

[0041] A deformable recovery aircraft, comprising a rocket body, canards 3, wings, air rudders 9, gas rudders 10, a parachute system, a thrust reverser engine system, and a landing gear system; figure 1 and figure 2 shown. The canard 3 is telescopically installed on both sides of the rocket body; the wings are installed on both sides of the rocket body; the air rudder 9 and the gas rudder 10 are all installed on the rocket body, Both are used for flight control; the parachute system is used for the deceleration of the aircraft in the subsonic section; the thrust reverser system is used for the deceleration of the aircraft before landing; the landing gear system is used for the landing of the aircraft .

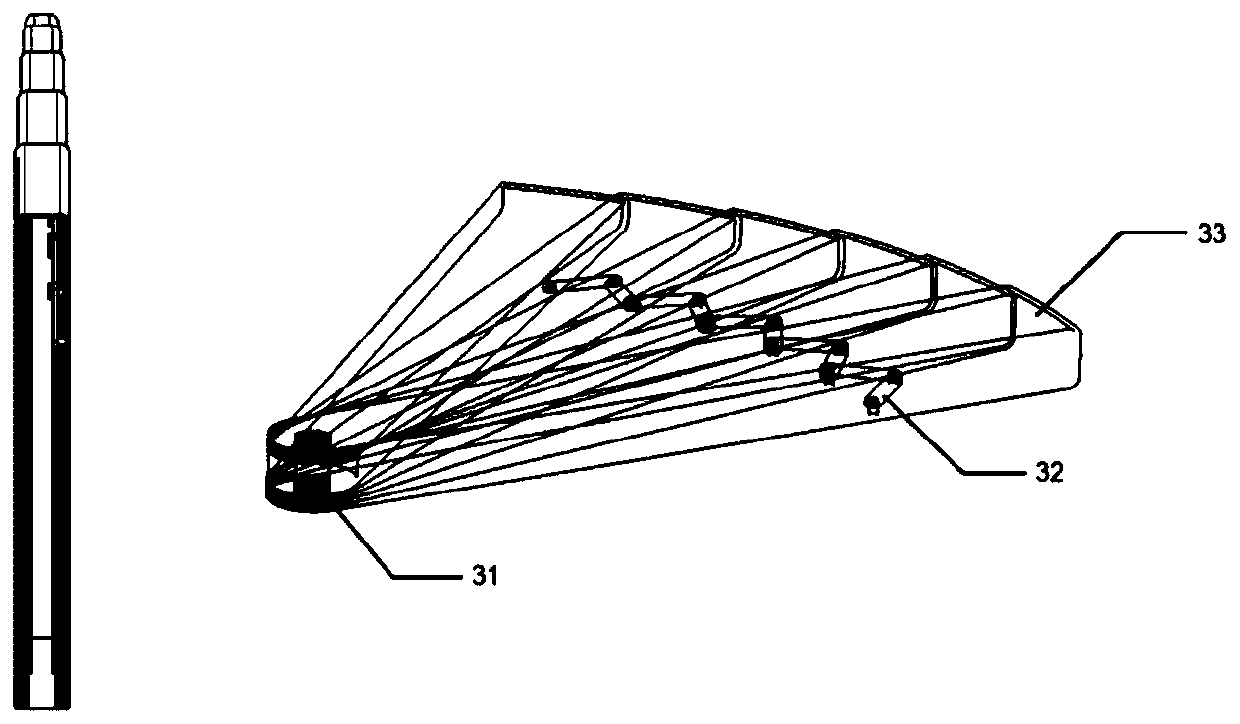

[0042] The canard 3 includes a motor-driven shaft 31, a folding link mechanism 32, and a plurality of wings 33; the plurality of wings 33 are connected through the folding link mechanism 32, that is, a plurality of wings 33 are stacked and set , the folding link mechanism ...

Embodiment 2

[0051] A deformable recovery aircraft, including a rocket body, a large-area wing that provides lift and deceleration in the hypersonic section, a pop-up canard that is trimmed in a wide speed range, an air rudder 9, a gas rudder 10, a parachute system for deceleration in the subsonic section, and a reverse Propulsion engine system, landing gear system.

[0052] The rocket body includes a task load compartment and a rocket body. The external task load 1 is located in the task load compartment. The task load compartment is closer to the incoming flow direction than the rocket body. The rocket body 2 is installed with the main engine for the ascent section of the aircraft. The flight control is controlled by The air rudder 9 and the gas rudder 10 are jointly realized. Described wing is made up of side strip wing 5, main wing 6 and winglet 7, is used for providing the lift in the gliding process of flight test and the resistance in the deceleration process, simultaneously side st...

Embodiment 3

[0063] A recovery method for a deformable recovery aircraft, using the deformable recovery aircraft described in Embodiment 1 or Embodiment 2, comprising the following steps:

[0064] Step 1. By increasing the angle of attack of the deformable recovery aircraft, the flight speed and altitude of the deformable recovery aircraft are reduced;

[0065] Step 2. When the flight speed of the deformable recovery aircraft does not exceed the first preset speed and the flight altitude does not exceed the first preset height, the canards 3 are ejected to reduce the angle of attack of the deformable recovery aircraft and lower the deformable recovery aircraft. The flight speed and flight altitude; in the present embodiment, the first preset speed is Mach number 2, and the first preset altitude is 25km;

[0066] Step 3. When the flight speed of the deformable recovery aircraft does not exceed the second preset speed and the flight altitude does not exceed the second preset height, open the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com