High-moisture sludge uniform-distribution drying device

A drying device and high-moisture technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc. Inconsistent drying effect and other problems, to achieve thorough drying effect, avoid uneven drying effect, and avoid inconsistent drying state from top to bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

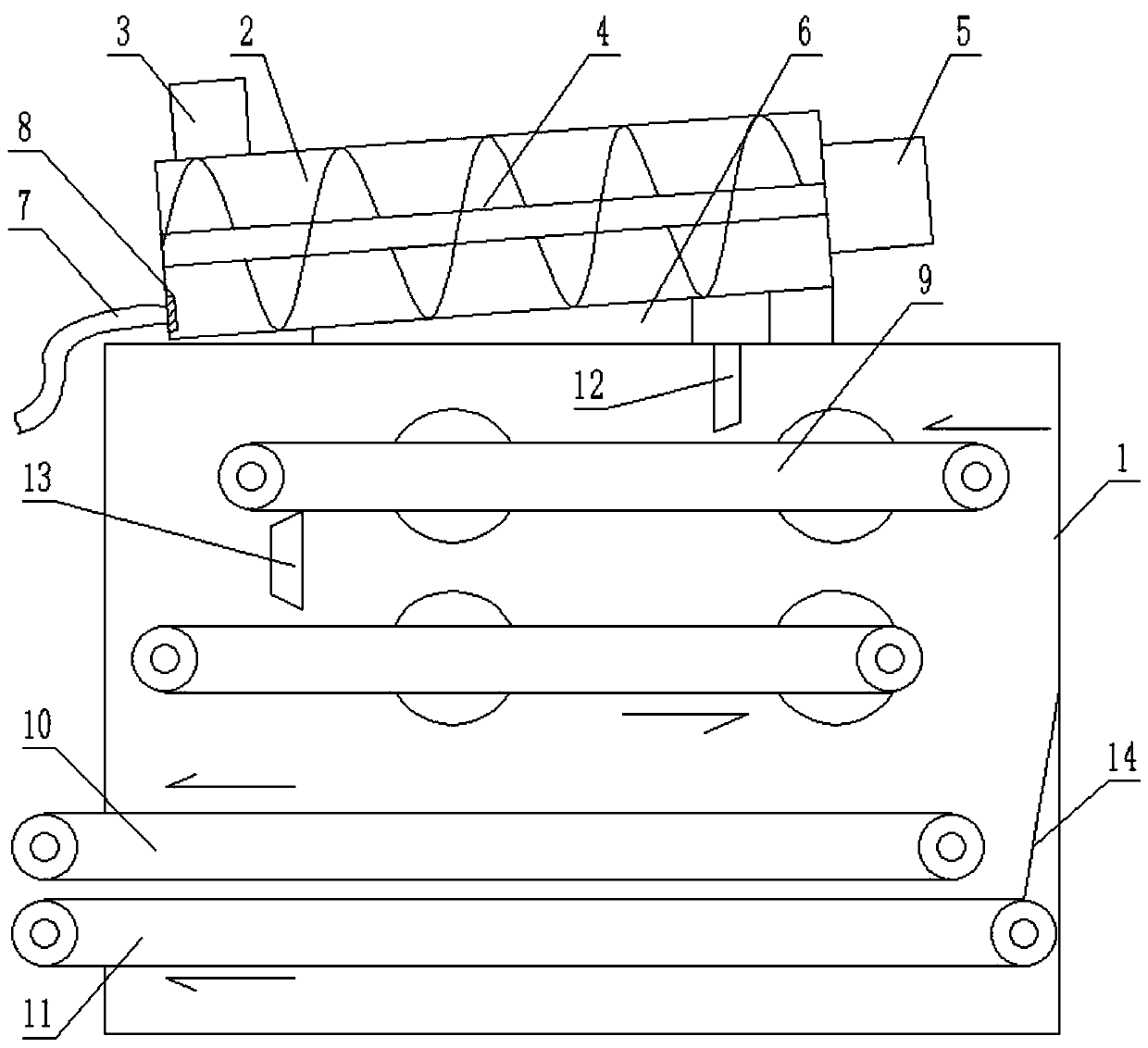

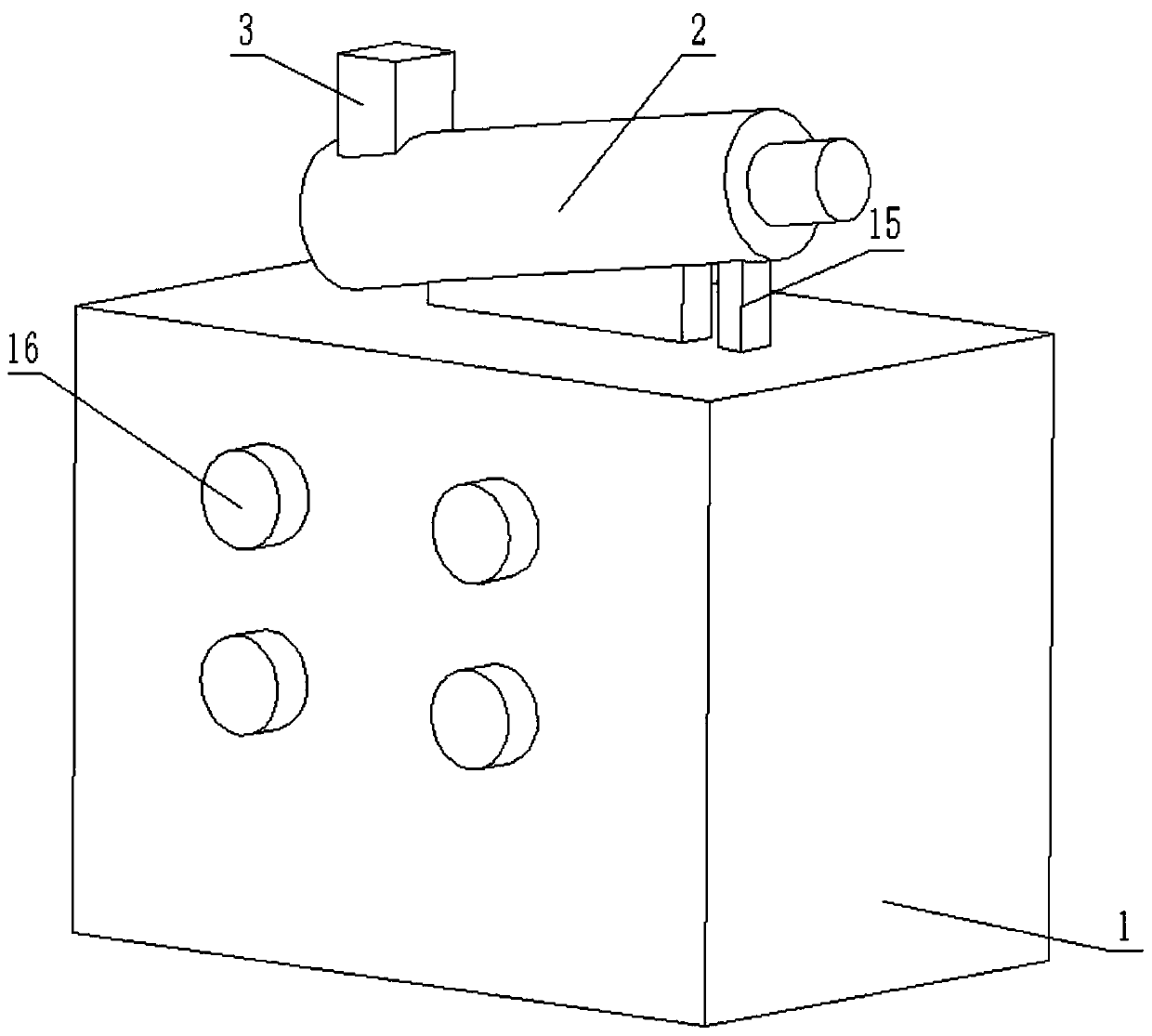

[0018] see Figure 1-2 , a high-moisture sludge evenly distributed drying device, comprising a box 1, a feeder 2 is provided above the box 1, two conveyor belts 9 parallel to each other are provided above the box 1, and two conveyor belts 9 are arranged below the conveyor belt 9. There is a forming structure, the forming structure includes an upper extrusion belt 10 and a lower extrusion belt 11 parallel to each other, a flat plate 12 is arranged on the top of the box body 1, a transfer plate 13 is provided between the two conveyor belts 9, and the transfer plate The upper and lower sides of 13 and the bottom surface of the flat plate 12 are all slopes, and the upper end of the transfer plate 13 is attached to the conveyor belt 9 above. The two sides of the box body 1 are respectively provided with a hot air fan 16 and an air outlet 17. The hot air is sent into the box 1 to dry the sludge, and the air outlet 17 is used to draw out the hot and humid gas. When drying the sludge,...

Embodiment 2

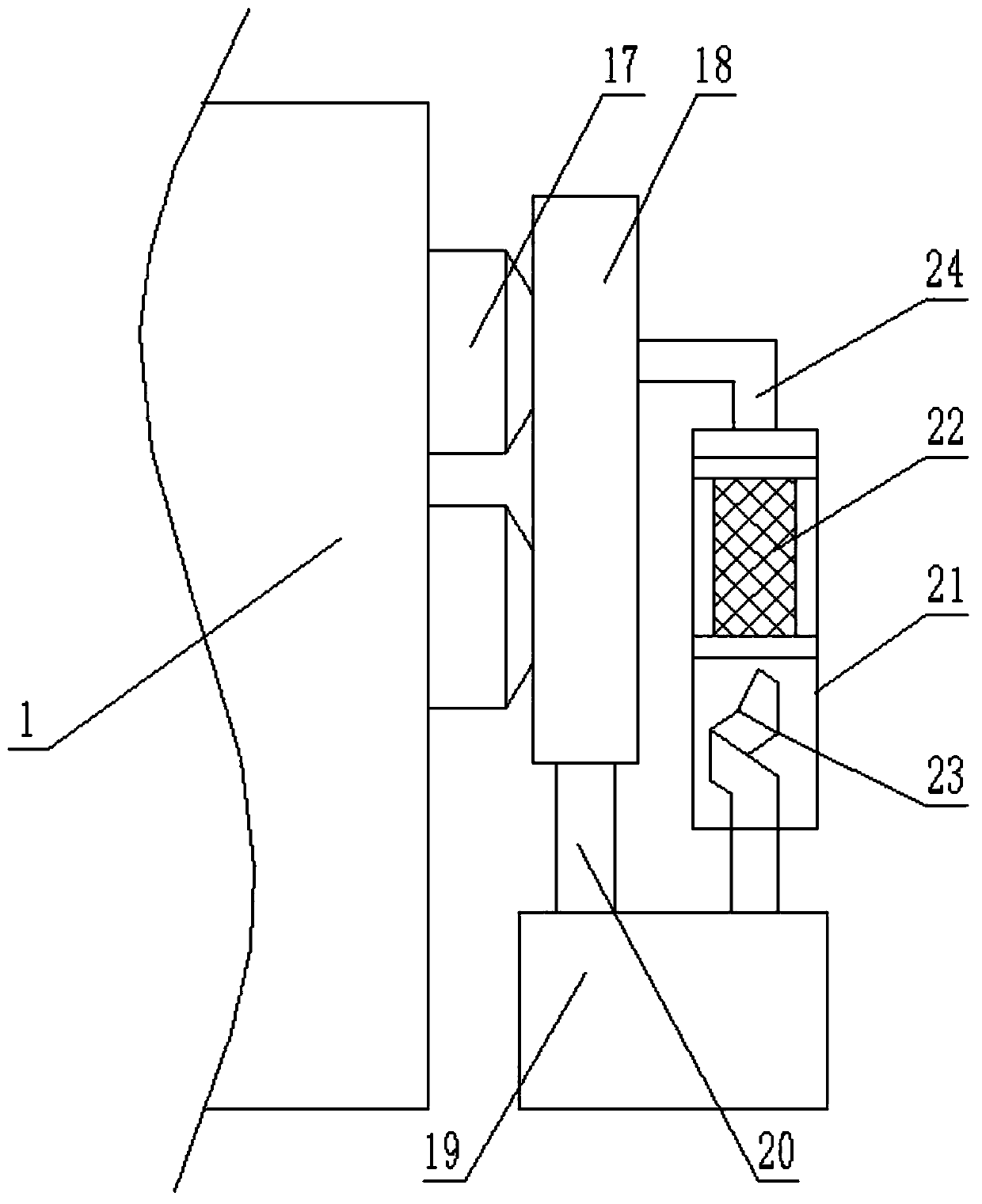

[0021] refer to image 3 , on the basis of Embodiment 1, in order to reduce energy consumption and reduce processing costs, a waste heat recovery mechanism connected to it is also provided on the side of the box body 1, and the waste heat recovery mechanism includes a dehumidification box 19 and a dust collector 21. The dehumidifier 21 is located above the dehumidification box 19, and the confluence box 18 connected to it through the air duct 20 is arranged above the dehumidification box 19. The confluence box 18 is set outside the air outlet 17. When the air outlet 17 discharges hot and humid air, it passes through the The box 18 and the air pipe 20 transfer the air to the dehumidification box 19, and the dehumidification box 19 is filled with dehumidification materials such as dehumidification cotton to remove the moisture in the air, and after the dust mixed in the air is cleaned by the dust collector 21, the obtained The high-temperature air is heated up again and sent int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com