Environment-friendly solid graphite lubricating composition and lubricant suitable for extreme temperature condition and preparation method of environment-friendly solid graphite and lubricant

A graphite lubricant and graphite lubrication technology, which is applied in the field of drilling materials, can solve the problems that lubricants are difficult to meet the use requirements, and achieve the effects of improving anti-adhesion performance, improving lubrication effect, and improving lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

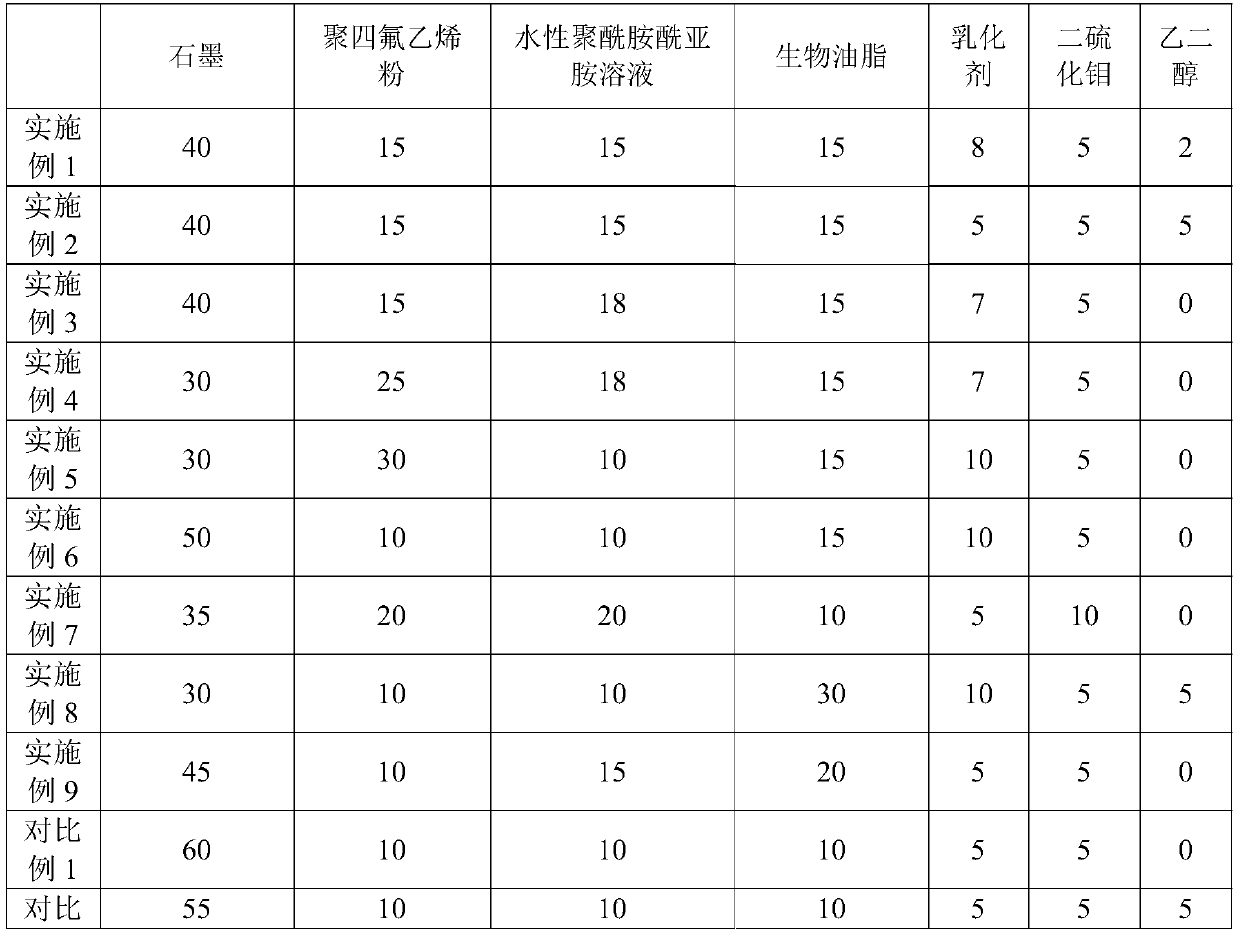

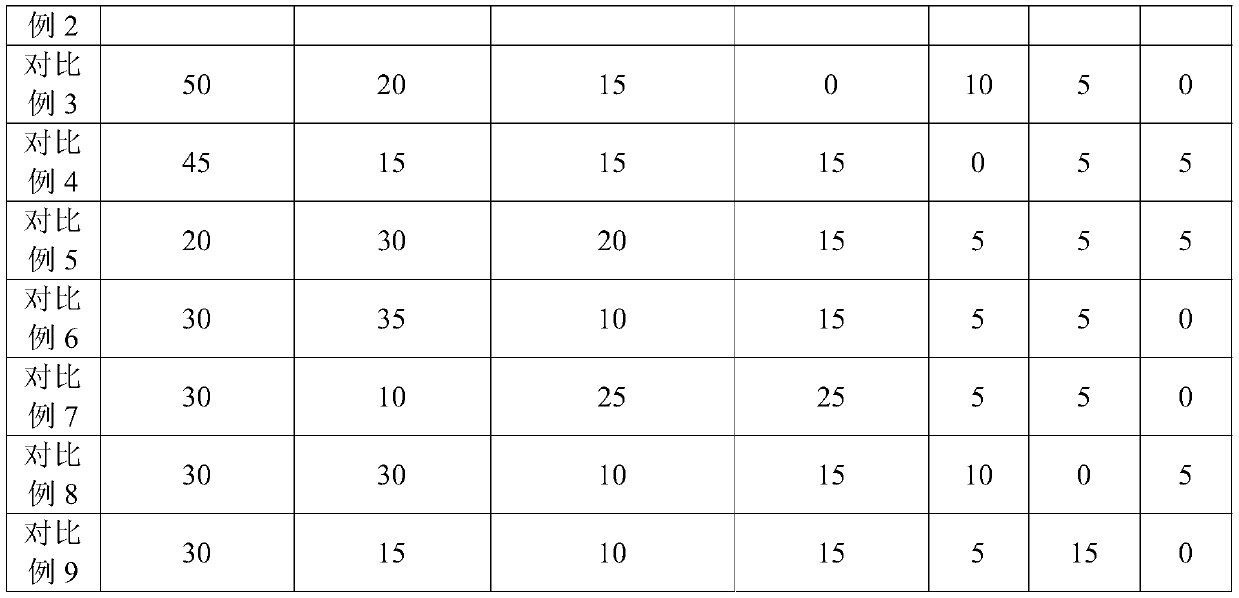

Embodiment 1

[0035] Add polytetrafluoroethylene powder, water-based polyamideimide solution, emulsifier, and optional ethylene glycol to the mixer for the first stirring to form the first mixed system; under the second stirring conditions Add graphite, molybdenum disulfide and bio-grease to a mixing system in turn. After the addition is complete, adjust the stirring speed and perform the third stirring to obtain an environmentally friendly solid graphite lubricant, polytetrafluoroethylene powder, water-based polyamide-imide solution, and emulsification The dosages of ethylene glycol, molybdenum disulfide, graphite and biological grease are shown in Table 1. Among them, graphite is flake graphite with a particle size of 100-500 mesh, PTFE powder is PTFE ultrafine powder, and water-based poly The solid content of the amide imide solution is 30%, the biological oil is vegetable oil, and the emulsifier is a mixture formed by mixing Span40 and Tween60 in a weight ratio of 1:2. The speed of the f...

Embodiment 10

[0041] The difference from Example 1 is that the bio-oil is animal fat,

Embodiment 11

[0043] The difference from Example 1 is that the bio-oil is animal fat,

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap