Spindle operation detecting system

A technology of running detection and spindle, which is applied in the field of spindle running detection system, can solve the problems of 0.5mm or even 1mm, affecting the direction of the spindle, economic loss, etc., to achieve accurate received information, simple structure, and prevent the direction of the spindle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

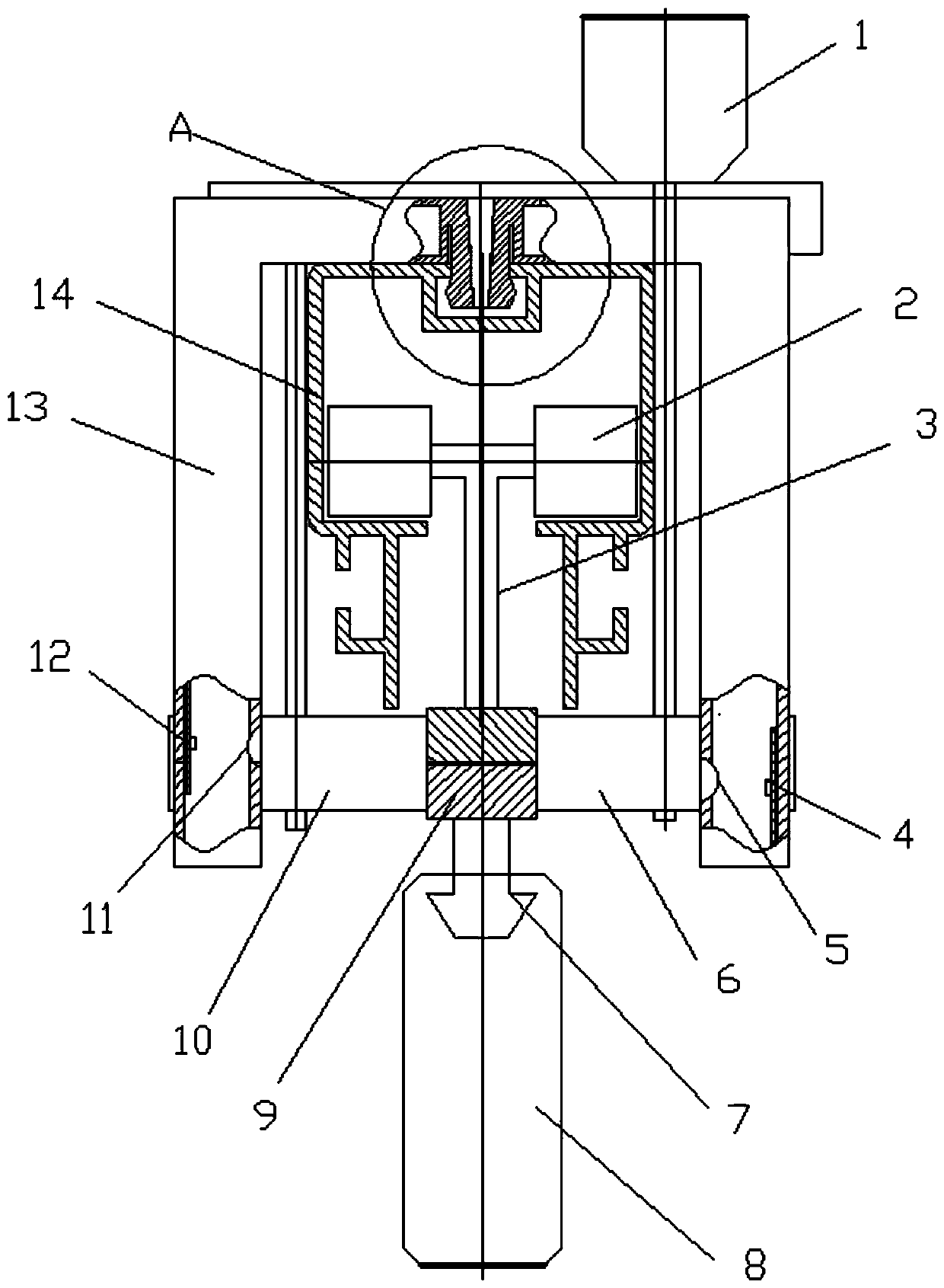

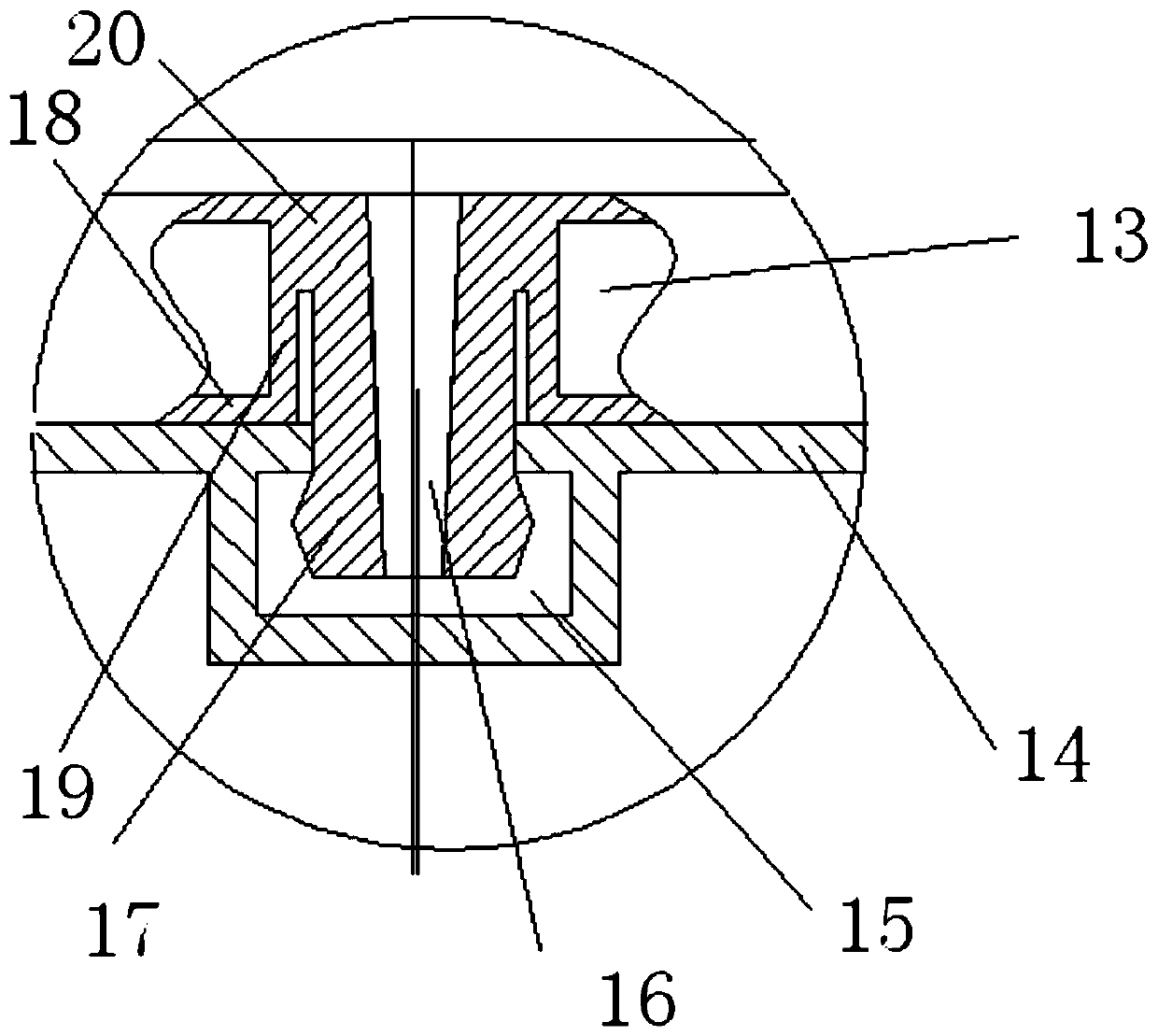

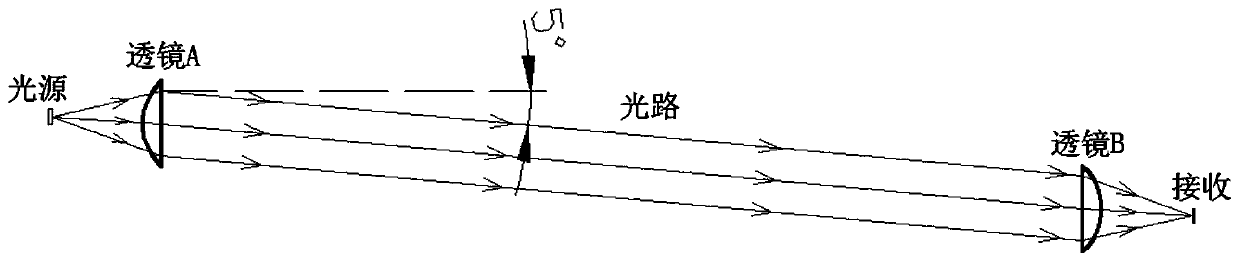

[0015] A spindle operation detection system, which includes a spindle transmission track 14, a plurality of spindle installation frames 3 with rollers 2, a spindle 8, a drive chain 9 and multiple sets of photoelectric detection devices, the rollers of the spindle installation frame are clamped on the spindle transmission rail Above, a yarn hook 7 is provided below the spindle installation frame, and the spindles are hung on the yarn hook. The fixed frame 13, the photoelectric transmitter 12 and the photoelectric receiver 4, the fixed frame is a door-shaped structure, which includes a top frame and two side frames, a motor 1 is fixedly installed on the spindle transmission track, and the motor shaft drives the driving sprocket 6 rotation, a driven sprocket 10 is installed next to the driving sprocket, and the drive chain is located between the driving sprocket and the driven sprocket and is driven by the driving sprocket to move along the extension direction of the spindle trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com