Production process of natural-color bamboo fiber antibacterial non-woven fabric for surface layers

A technology for non-woven fabrics and production processes, applied in non-woven fabrics, textiles and papermaking, drying gas layout, etc., can solve the problems of no natural bacteriostatic effect, chemical fiber allergy, low absorption rate, etc., and achieve the problem of not easy allergy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A kind of natural color bamboo fiber bacteriostatic surface layer of the present invention uses the non-woven fabric production process, non-woven fabric comprises 70-80 parts of natural color bamboo fiber, 20-30 parts of chitosan fiber, comprises the following steps:

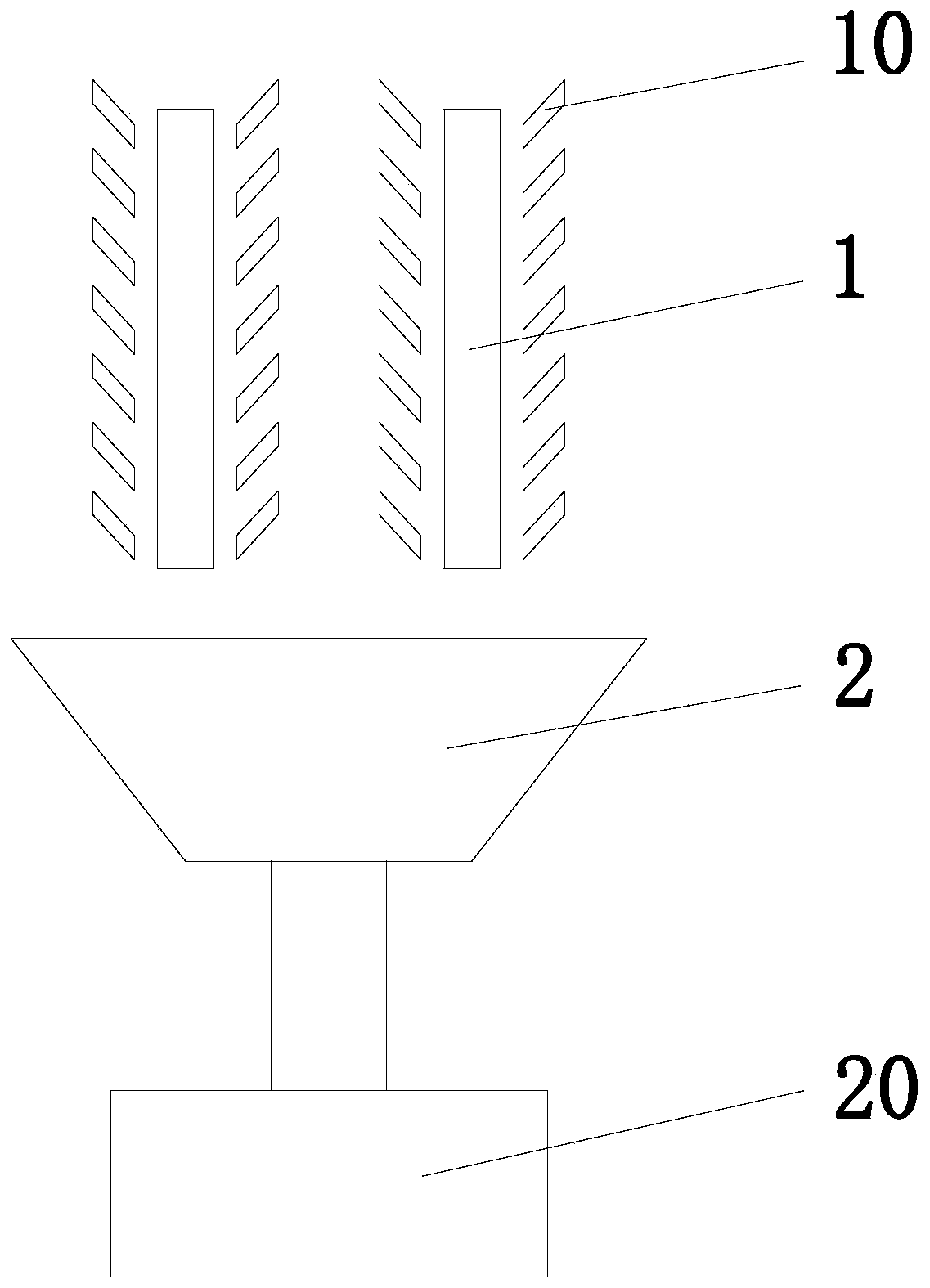

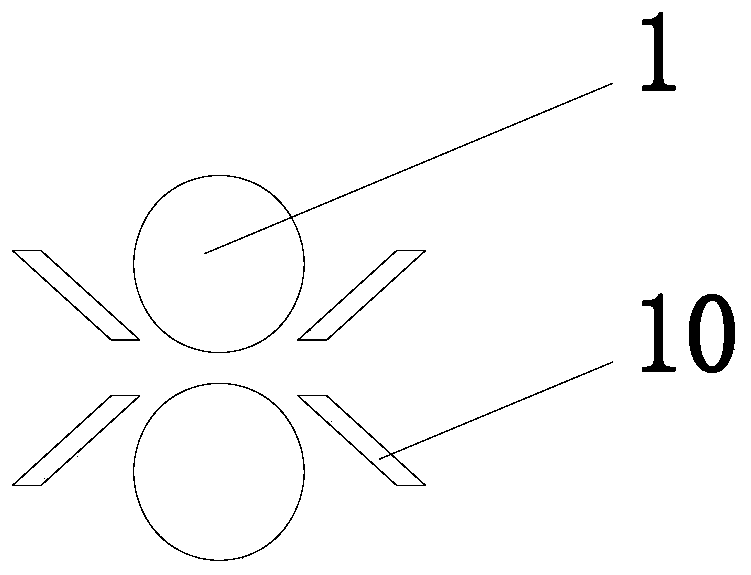

[0021] Step 1: introducing natural color bamboo fiber and chitosan fiber into a carding machine to card into a web;

[0022] Step 2: Spunlace reinforcement of the laid fiber web through a spunlace process;

[0023] Step 3: Put the spunlace-strengthened nonwoven fabric into the drying equipment for drying treatment;

[0024] Step 4: Roll up the dried nonwoven fabric, inspect it, pack it, and put it into storage.

[0025] The ratio of the introduction speed of natural color bamboo fiber and chitosan fiber in the step 1 is the ratio of the content of the two. In the step one, the carding machine adopts one of straight laying, semi-cross-laying and cross-laying when laying the web. The nonwoven fabric is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com