Cooling type water permeable brick for sponge city

A technology of sponge city and permeable bricks, which is applied to pavements, roads, and pavement details paved with prefabricated blocks. It can solve the problems of poor water storage and cooling effects, and achieve the goals of improving utilization, expanding area, and speeding up drainage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

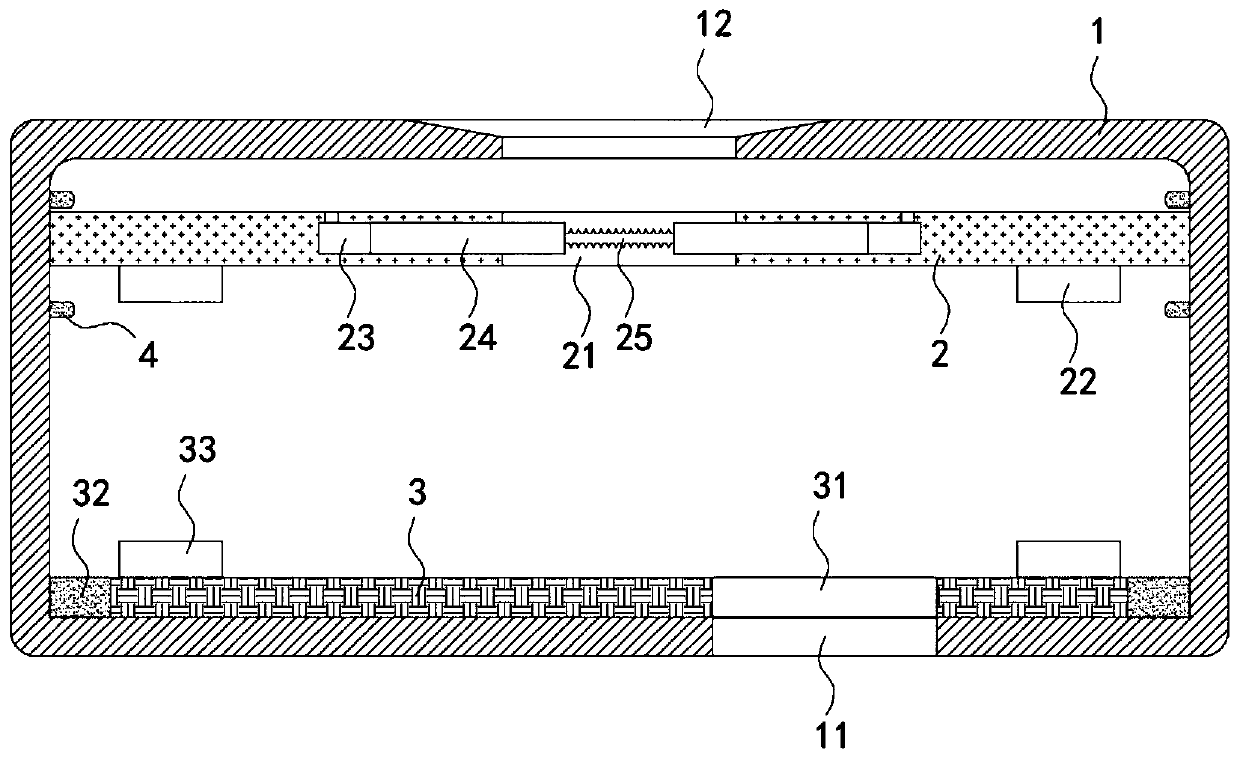

[0026] like figure 1 As shown, a cooling type water permeable brick for sponge city includes a brick body 1, and the inside of the brick body 1 is provided with a cavity. The bottom opening is arranged and communicated with the inside of the brick body 1, so that the rainwater on the road surface can be collected quickly and flow into the brick body 1, thereby speeding up the drainage speed of the road surface and the infiltration of rainwater.

[0027] In this embodiment, the lower surface of the brick body 1 is provided with permeable holes 11, and the inner wall of the brick body 1 is slidably connected with a lifting plate 2. The density of the lifting plate 2 is smaller than that of water. It should be noted that the inner wall of the brick body 1 The upper part is fixedly connected with two limit rings 4 for limiting the lifting plate 2, which can limit the lifting plate 2, the lifting plate 2 is provided with a through hole 21, and the inner bottom surface of the brick ...

Embodiment 2

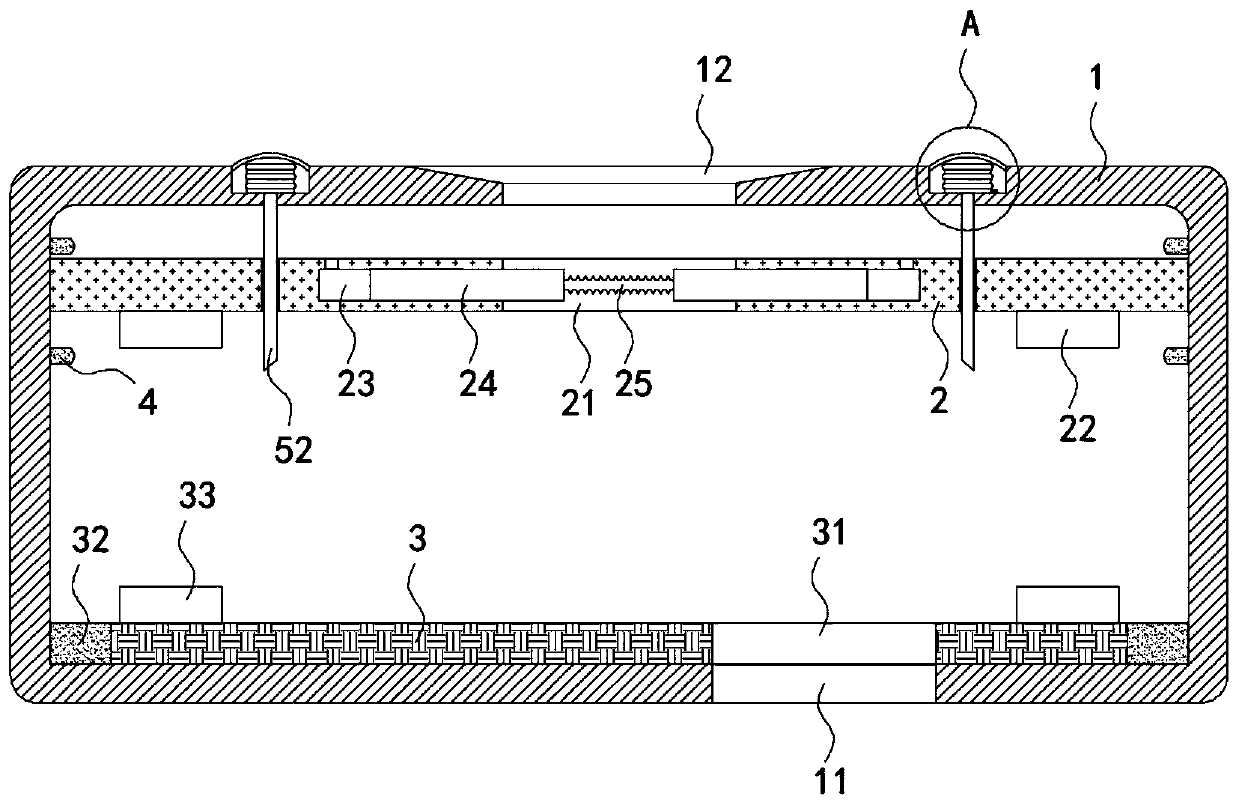

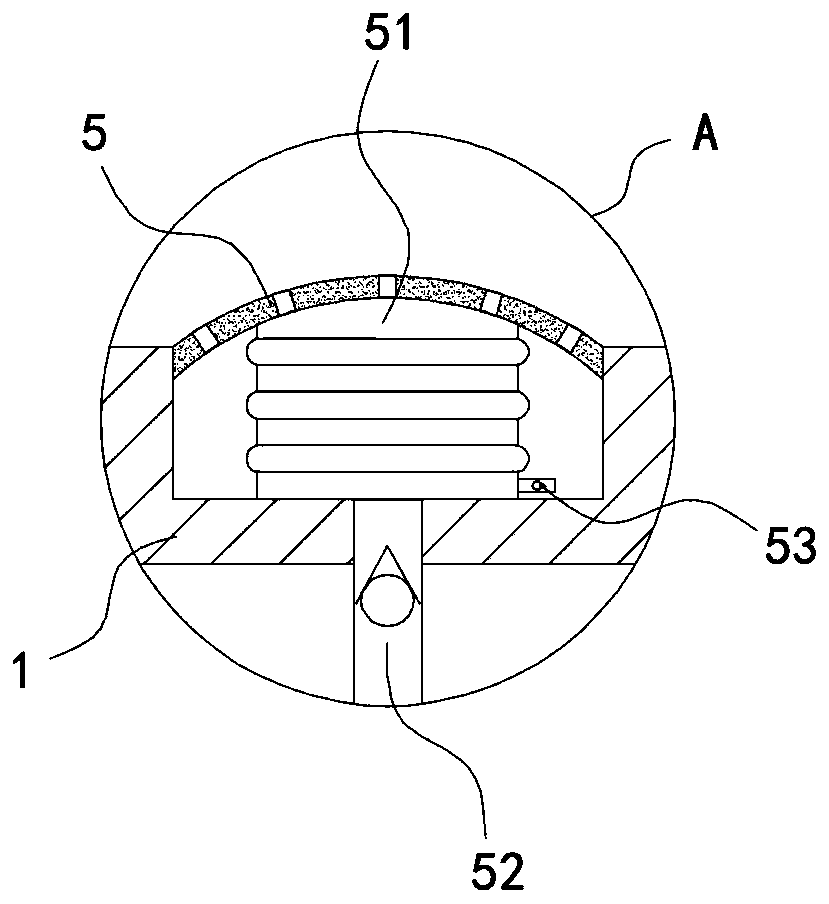

[0033] like Figure 2-4 As shown, the difference between this embodiment and Embodiment 1 is that the upper surface of the brick body 1 is provided with a groove, and the side wall of the groove is fixedly connected with an arc-shaped and upwardly arched flexible pedal 5. It is illustrated that a plurality of flexible pedals 5 are arranged in an annular array on the upper surface of the brick body 1. The flexible pedals 5 are porous and the surface is provided with anti-slip protrusions, which play a good anti-skid effect and prevent pedestrians from walking on rainy days due to the brick surface. Smooth and fall, the lower surface of the flexible pedal 5 is fixedly connected with the bottom surface of the groove through the airbag 51, the lower end of the airbag 51 is fixedly connected with a one-way blowing pipe 52, and the one-way blowing pipe 52 only allows the gas in the airbag 51 to blow to the brick. Inside the body 1, the lower end of the one-way blowing pipe 52 runs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com