Joint for enabling independent latticed column to pass through inner supporting beam and construction method for joint

A technology of supporting beams and lattice columns, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of long occupation time of foundation pits and basement structures, difficult construction of multi-storey basement structures, and late completion of positive and negative zero floor slabs, etc. problems, to achieve the effect of guaranteeing section width and construction quality, ensuring safety and stability, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

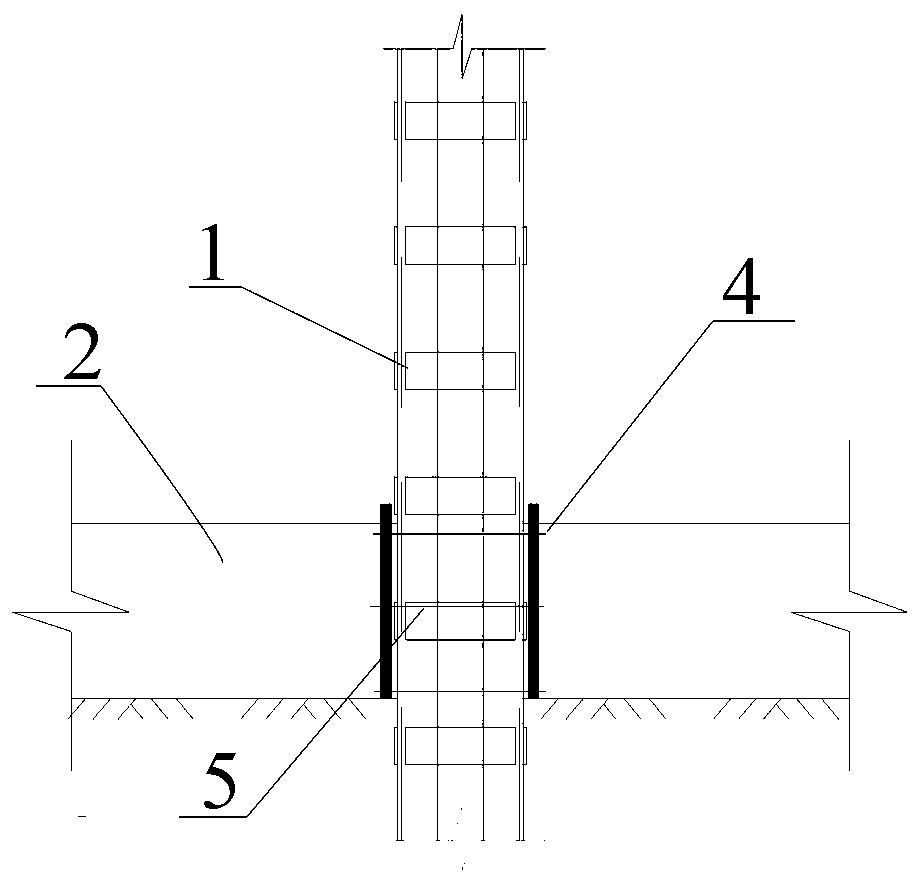

[0044] In this embodiment, the construction method of the support device installed on the steel column of the foundation floor is as follows:

[0045] Step 1: Install polystyrene boards within the coverage of the inner support beams on the four sides of the independent lattice columns, and the polystyrene boards are fixed with binding iron wires;

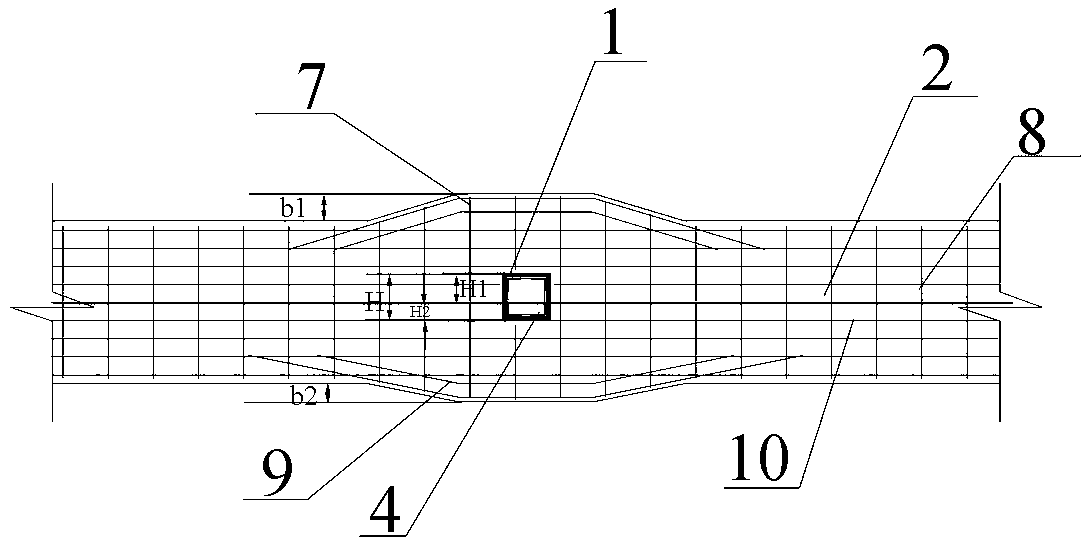

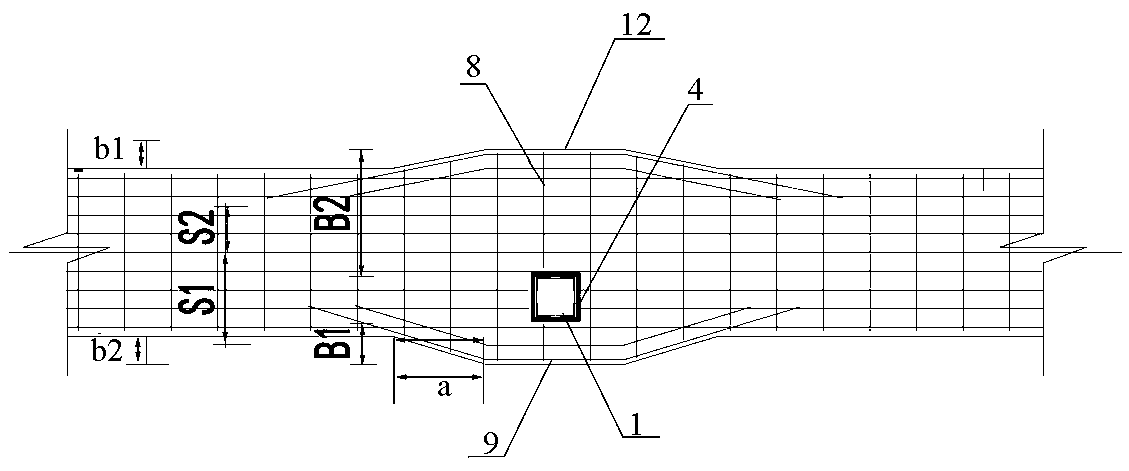

[0046] Step 2: Position and set out the internal support of the independent lattice column, determine the positional relationship between the independent lattice column and the internal support beam, whether it is located at the center line and the distance from the center line, and determine the beam width L of the internal support beam.

[0047] Step 3: Bind the stirrups of the inner support beam and the main reinforcement of the inner support beam according to the requirements of the drawings. The main reinforcement of the inner support beam is disconnected when it meets the polystyrene board, and the stirrups of the inner support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com