Gas well gas-liquid separating producing well completion pipe string

A completion string, gas-liquid technology, applied in wellbore/well components, drill pipe, casing, etc., can solve the problem of disconnection between oil and casing, difficult to control gas wells with liquid and water flooding, and difficult to apply to low pressure and high pressure. Problems such as the demand for liquid discharge and gas production in liquid volume wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below by specific embodiment:

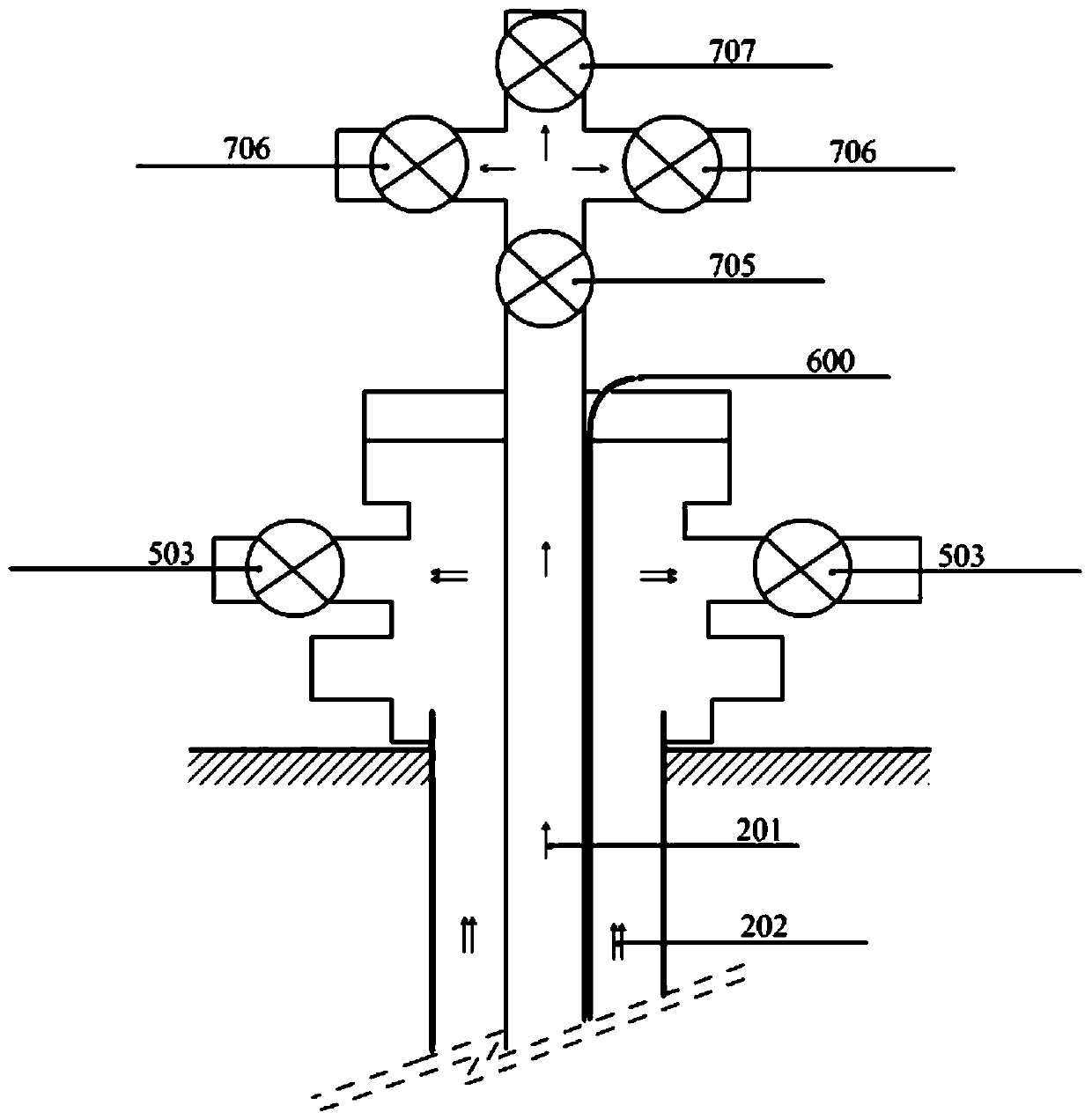

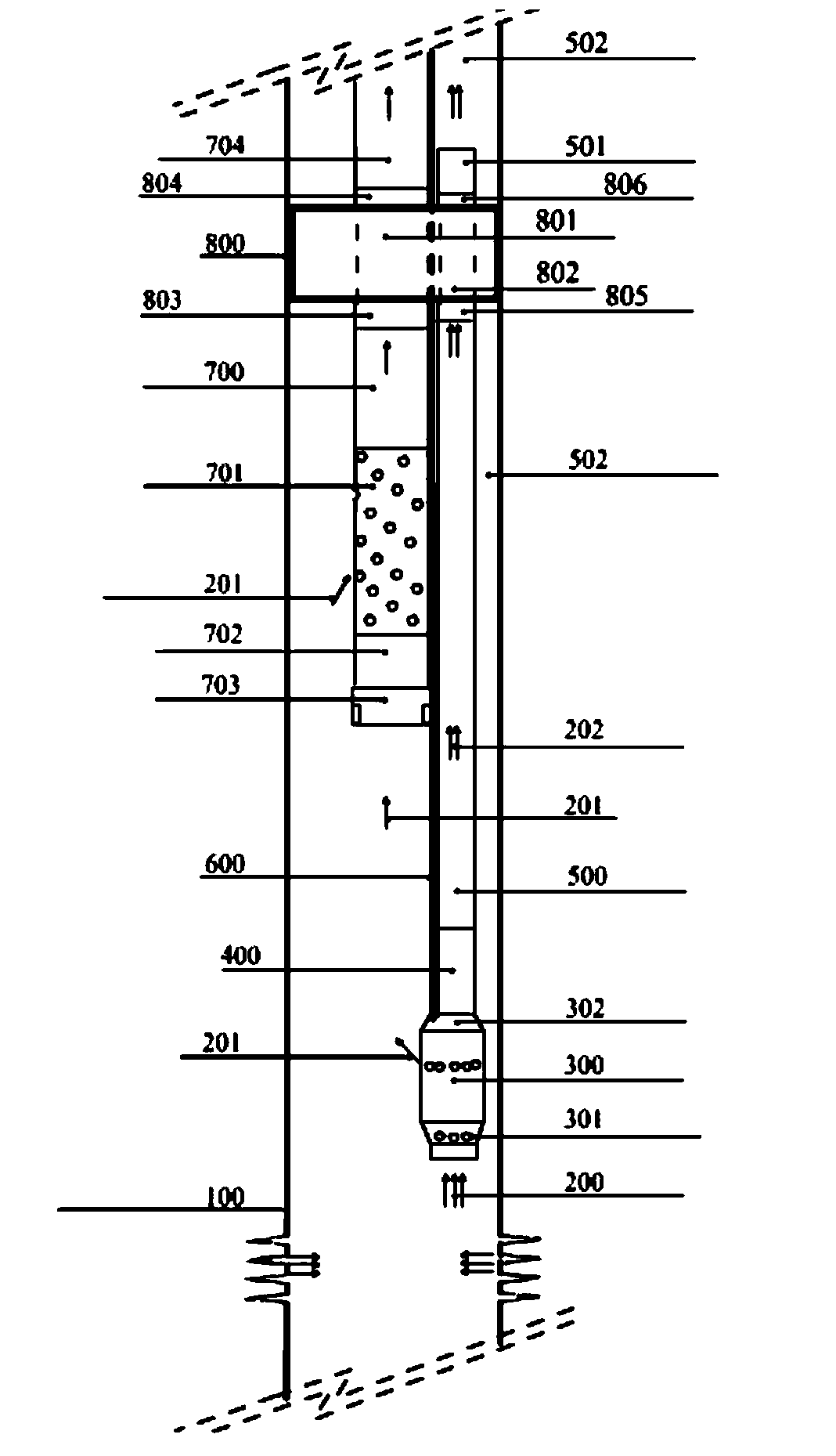

[0024] see figure 1 and figure 2 , a gas well gas-liquid separate recovery completion string provided by the present invention includes a wellbore 100, a deep submersible pump 300 arranged at the bottom of the wellbore 100, a gas production tubing 700 and a liquid discharge tubing 500 vertically arranged in the wellbore 100.

[0025] The deep submersible pump 300 should have a gas-liquid separation function, and it is mainly composed of pumps, separators, protectors, motors and other components. Since it is a prior art, it will not be repeated here. The deep submersible pump 300 is in the shape of a cylinder placed vertically in the wellbore 100. The bottom of the deep submersible pump 300 is provided with a liquid inlet 301, the side wall of the deep submersible pump 300 is provided with an exhaust hole, and the top of the submersible pump 300 is provided with a discharge port. Outlet 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com