Pneumatic ball valve for hypervelocity wind tunnel throat and processing method of pneumatic ball valve

A pneumatic ball valve, ultra-high-speed technology, applied in valve details, valve device, valve shell structure, etc., to achieve the effect of preventing scouring, good consistency and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

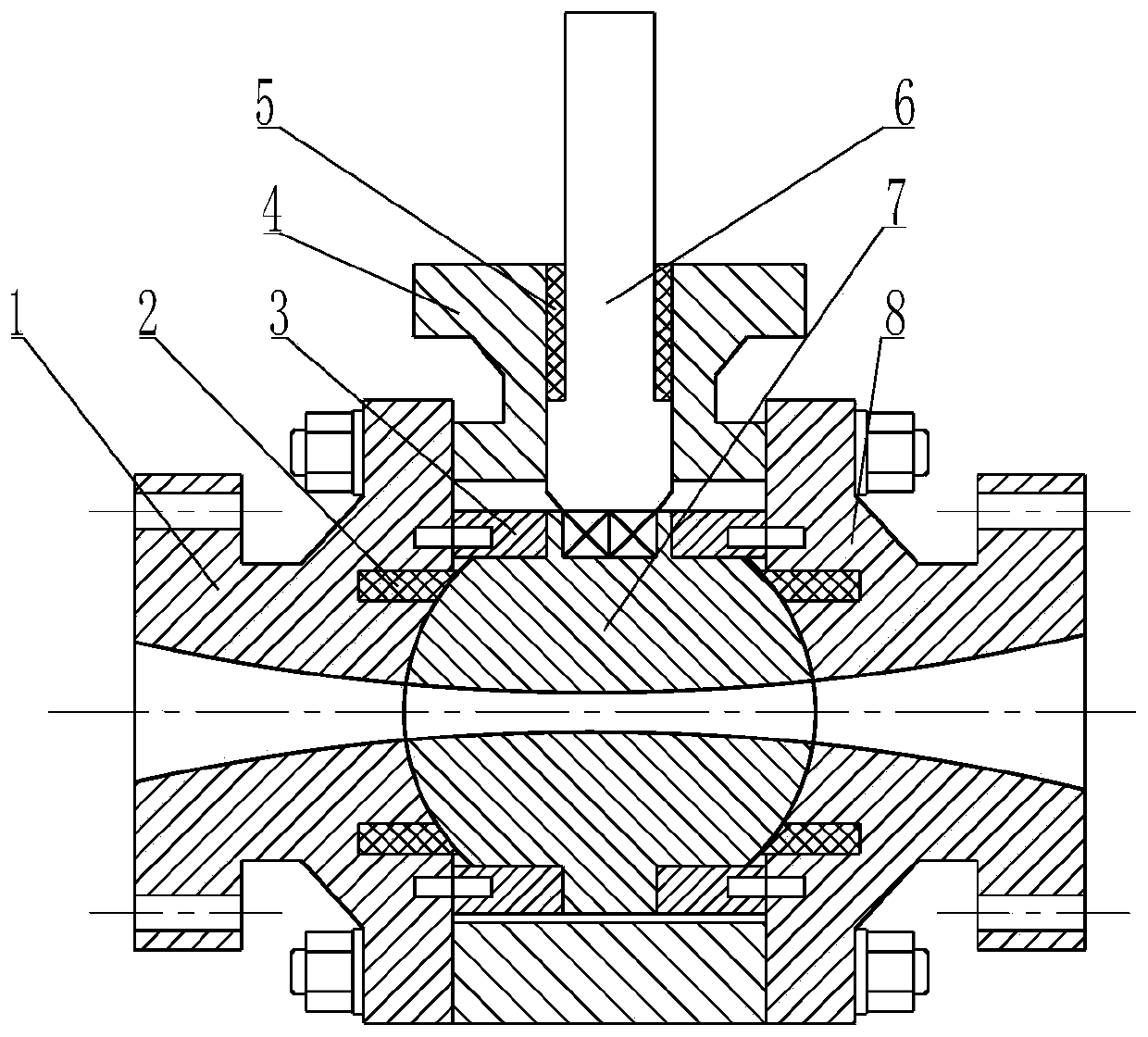

[0030] Such as figure 1 As shown, the pneumatic ball valve for ultra-high-speed wind tunnel throat of the present invention includes a left end cover 1, a valve seat 2, a support plate 3, a valve body assembly 4, a packing seal assembly 5, a valve stem 6, a ball core 7 and a right end cover 8;

[0031] Left end cover 1: the left end cover of the pneumatic ball valve, with a central through hole Ⅰ inside;

[0032] Valve seat 2: used for sealing the ball core 7;

[0033] Support plate 3: used to support the ball core 7;

[0034] Valve body assembly 4: the valve body part of the pneumatic ball valve;

[0035] Packing seal assembly 5: used for sealing between the valve body and the valve stem;

[0036] Valve stem 6: used to drive the ball core 7 to rotate, so as to realize the opening and closing functions;

[0037] Ball core 7: there is a central through hole II inside;

[0038] Right end cover 8: the right end cover of the ball valve, with a central through hole III inside;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com