Urea liquid level real-time detection method and system

A technology of real-time detection and urea solution, which is applied in the direction of buoy liquid level indicator, liquid/fluid solid measurement, measuring device, etc. It can solve the problems of large liquid level display intervals, jumps, and inability to judge urea consumption in real time, and achieve Improve user experience, ensure continuity, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

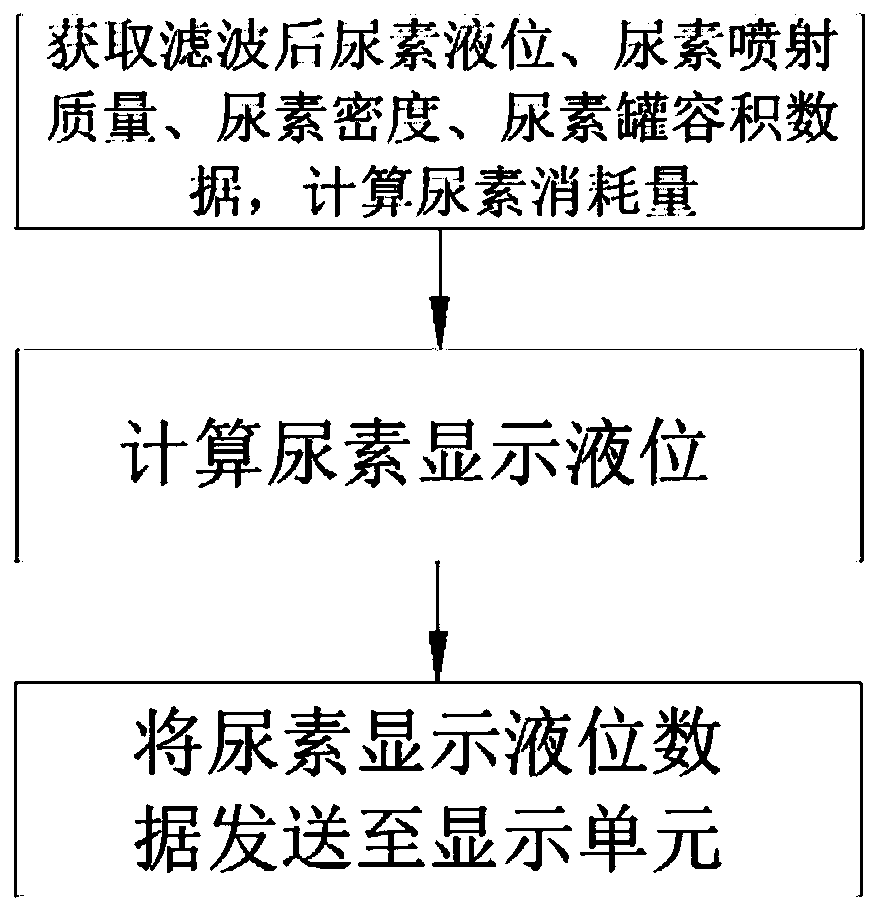

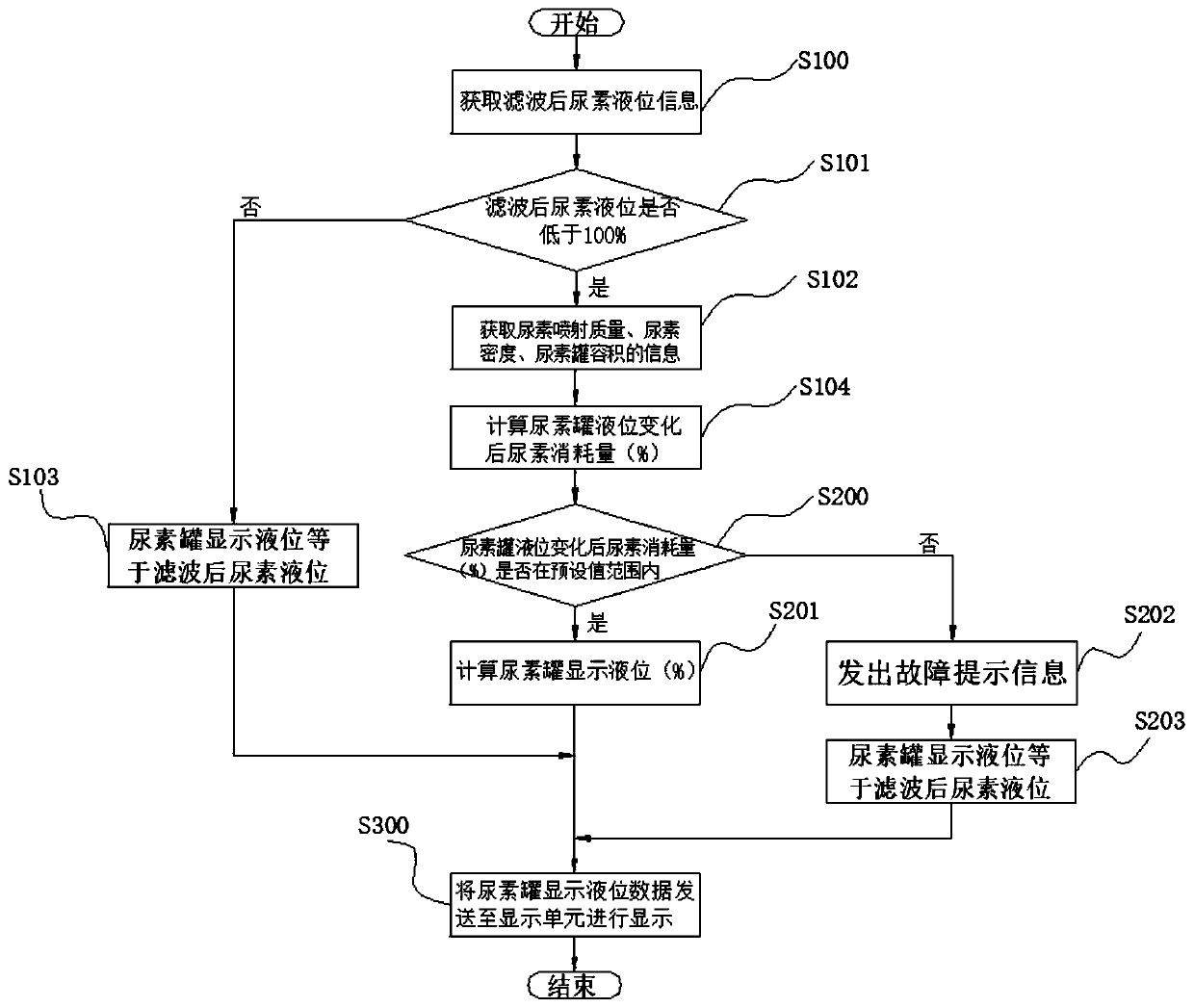

[0109] The present embodiment provides a real-time detection method for urea liquid level, and the real-time detection method comprises the following steps:

[0110] S100, collecting and obtaining the filtered urea liquid level, and proceeding to step S101 for logical judgment;

[0111] S101, judging whether the filtered urea liquid level is lower than 100%, if the judging result is yes, go to step S102;

[0112] S102, collect and acquire the data of urea injection quality, urea density and urea tank volume, and enter step S104;

[0113] S104, calculate the urea consumption after the liquid level change of the urea tank through the data collected in step S102, and enter step S200 for logic judgment;

[0114] S200, judging whether the urea consumption is within the preset value range, if the judging result is yes, go to step S201;

[0115] S201. Calculate the displayed liquid level of the urea tank according to the urea consumption and the filtered urea liquid level data, and...

Embodiment 2

[0118] The present embodiment provides a real-time detection method for urea liquid level, and the real-time detection method comprises the following steps:

[0119] S100, collecting and obtaining the filtered urea liquid level, and proceeding to step S101 for logical judgment;

[0120] S101, judging whether the filtered urea level is lower than 100%, if the judging result is no, go to step S103;

[0121] S103. Determine the filtered urea liquid level as the displayed liquid level of the urea tank, and proceed to step S300;

[0122] S300. Send the displayed liquid level data of the urea tank to the display unit for the user to view. At this time, the user sees the full liquid level of the urea tank, and the process ends.

Embodiment 3

[0124] The present embodiment provides a real-time detection method for urea liquid level, and the real-time detection method comprises the following steps:

[0125] S100, collecting and obtaining the filtered urea liquid level, and proceeding to step S101 for logical judgment;

[0126] S101, judging whether the filtered urea liquid level is lower than 100%, if the judging result is yes, go to step S102;

[0127] S102, collect and acquire the data of urea injection quality, urea density and urea tank volume, and enter step S104;

[0128] S104, calculate the urea consumption after the liquid level change of the urea tank through the data collected in step S102, and enter step S200 for logic judgment;

[0129] S200, judging whether the urea consumption is within the preset value range, if the judging result is no, go to step S202;

[0130] S202, enter step S203 after sending out the fault prompt message;

[0131] S203. Determine the filtered urea liquid level as the displayed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com