Method for measuring relationship between adhesion coefficient and slip rate under brake of railway vehicle and test bench

An adhesion coefficient, railway vehicle technology, applied in the field of railway vehicle adhesion characteristics testing, can solve problems such as difficulty, long line test time, inability to meet, etc., to reduce the test risk, improve the anti-skid exhaust structure, and reduce the power demand of the motor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

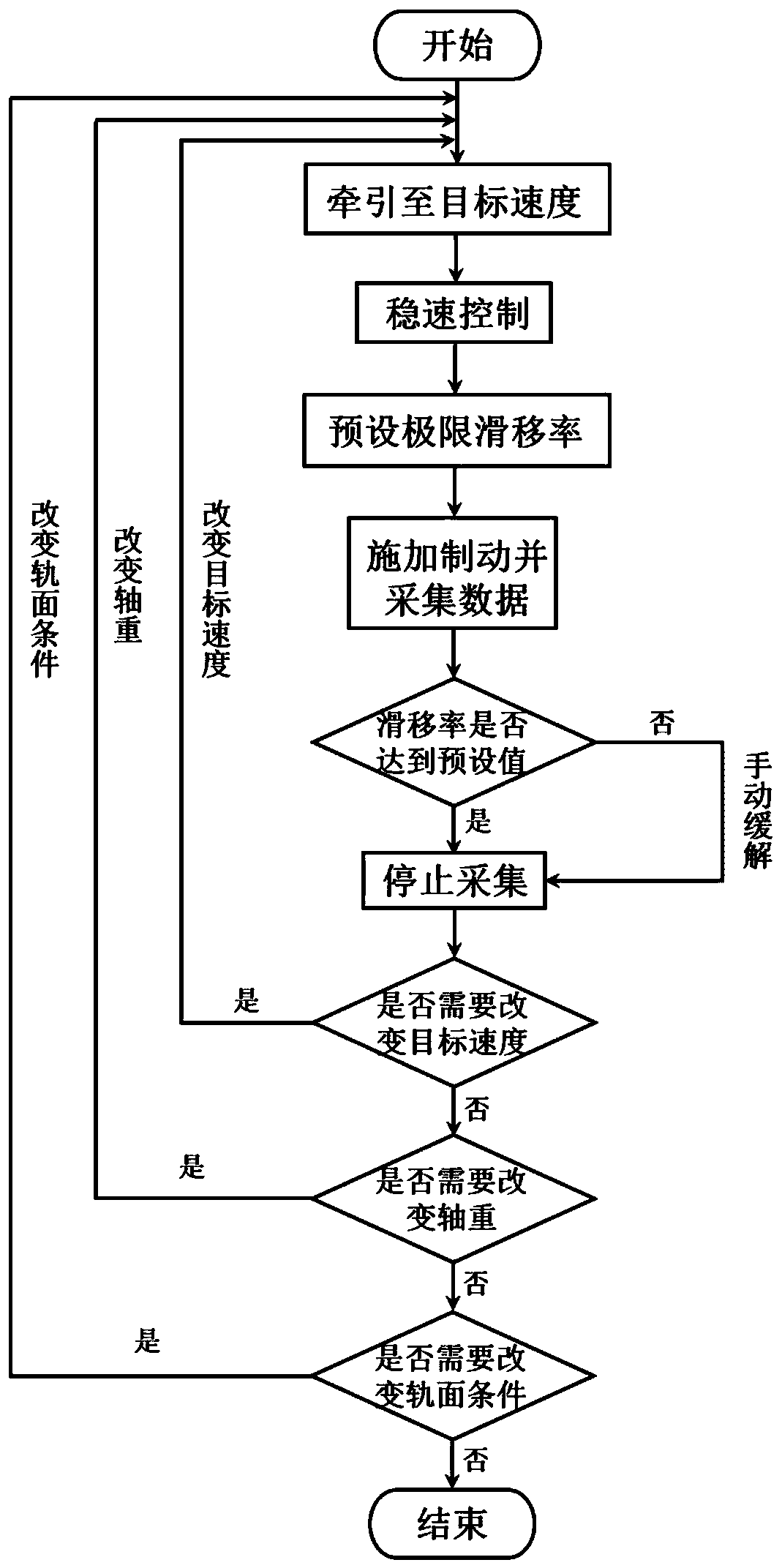

[0043] A test rig and method for measuring the relationship between the adhesion coefficient and the slip rate under the braking condition of a railway vehicle based on a rolling test rig. The specific implementation methods are as follows:

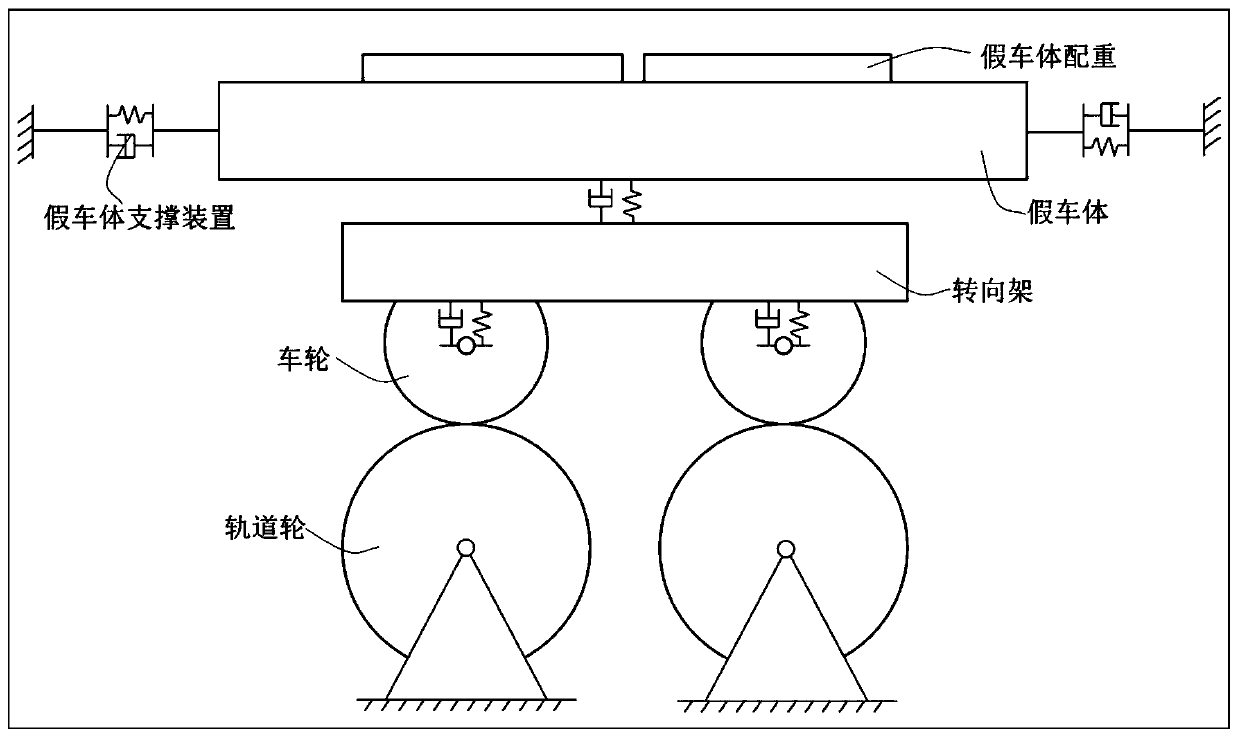

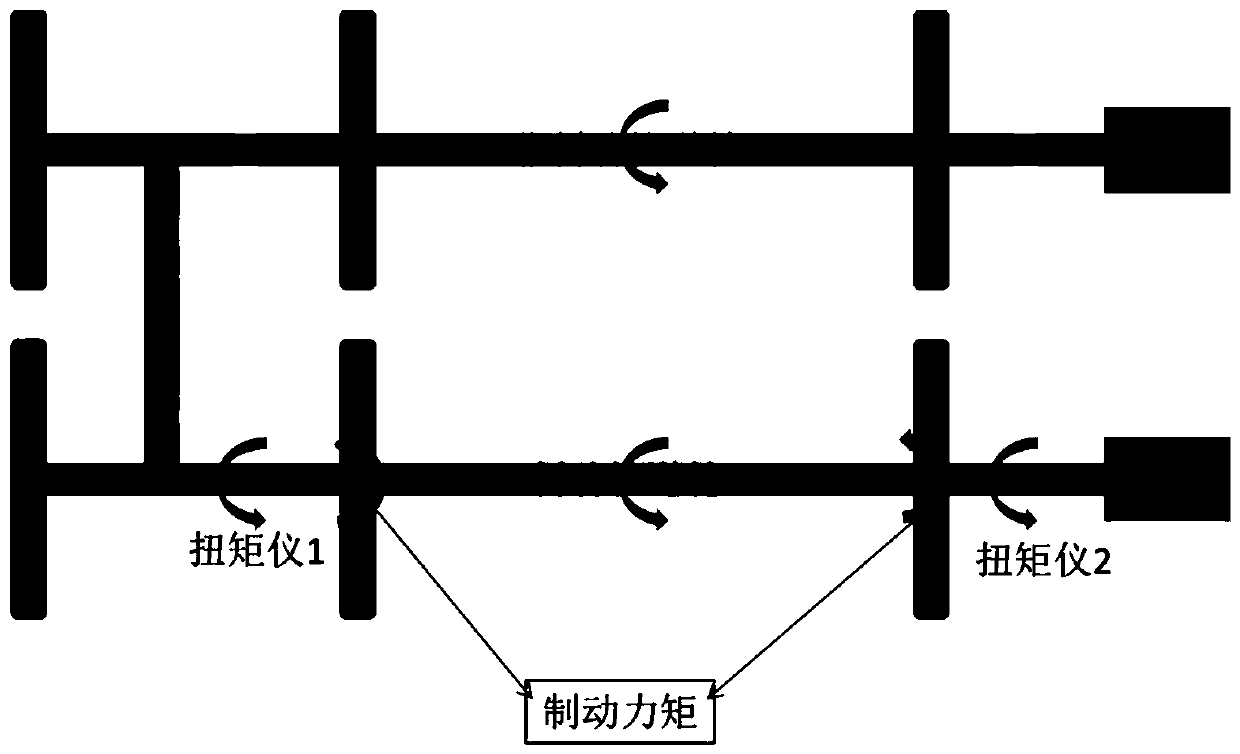

[0044] Rolling test bench for measuring such as figure 1 As shown, it includes rail wheels, bogies, dummy car bodies, dummy car body support devices, dummy car body counterweights, etc., including rail wheel traction motors not shown in the figure, and synchronous gears connecting two rail wheel pairs. Gearboxes, flywheels as inertial loads, and torque meters, encoders, speed sensors, and acquisition systems.

[0045] Preparation of measuring equipment includes:

[0046] Connect the two pairs of track wheels of the test bench with a synchronous gearbox so that they can rotate synchronously;

[0047] The moment of inertia of the mechanical flywheel set equipped on the test bench is configured to the maximum without considering the equiva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com