System for disconnecting or connecting drainage wire of distribution network in alive state and method thereof for disconnecting or connecting drainage wire

A flow line and distribution network technology, applied in the field of connecting and draining lines, connecting and draining line systems and their disconnection, and distribution network live disconnection, can solve the problems of no operation end, complex structure of the end, low performance, etc., to reduce the complexity, The effect of improving work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

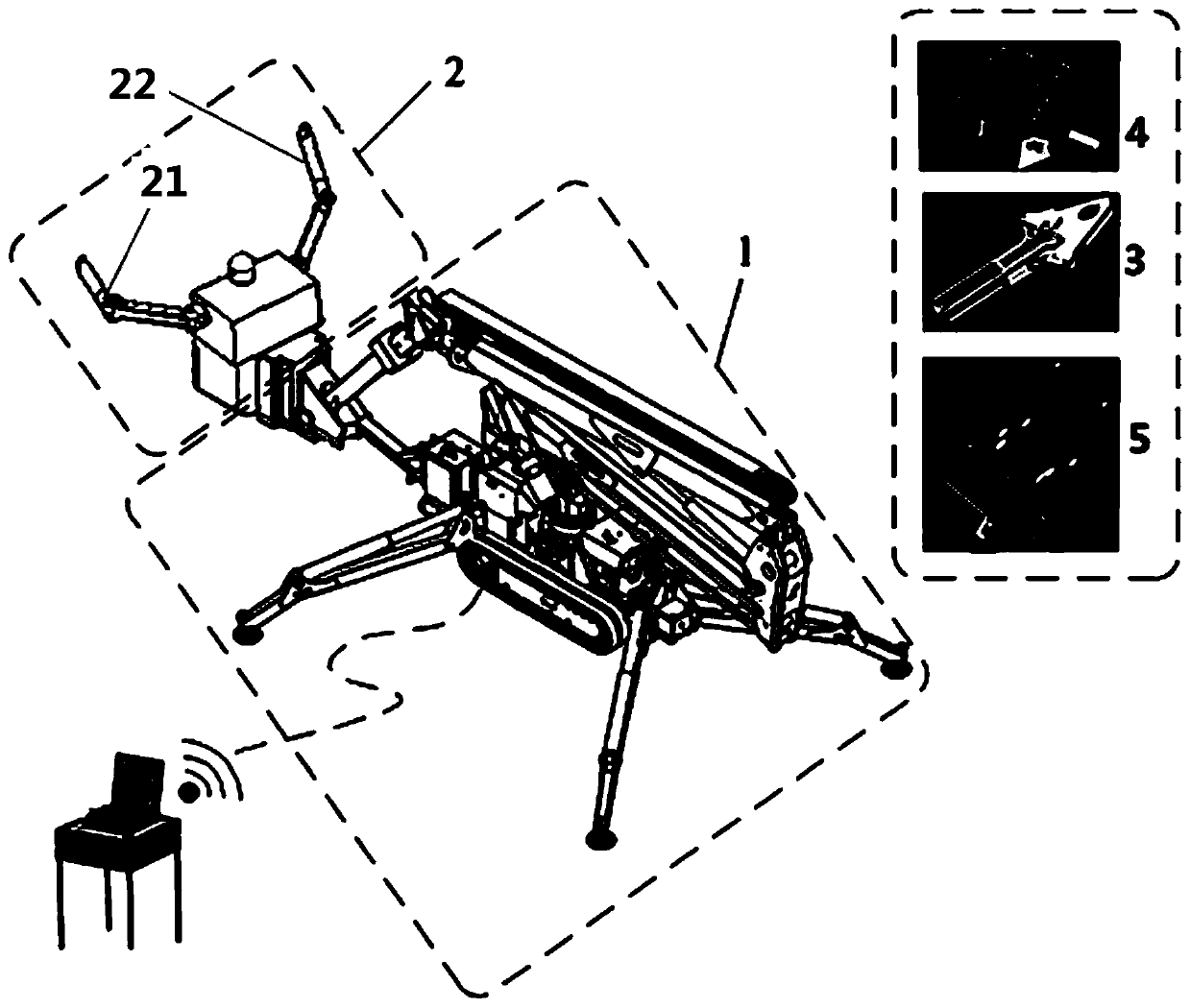

[0036] Such as figure 1 As shown, the distribution network live disconnection and drain line system disclosed in this embodiment includes a crawler-type aerial work vehicle 1 and a working robot platform 2 installed at the end of its telescopic arm.

[0037]The crawler-type aerial work vehicle 1 of this embodiment preferably outsources the Italian crawler spider vehicle represented by Changzhou Xinlanling Power Auxiliary Equipment Co., Ltd., which can walk by remote control and has three large arms and telescopic arms. The end section of the telescopic arm is an insulating section. , It is also equipped with four retractable outriggers, and when the outriggers are supported on the ground, the crawler is off the ground.

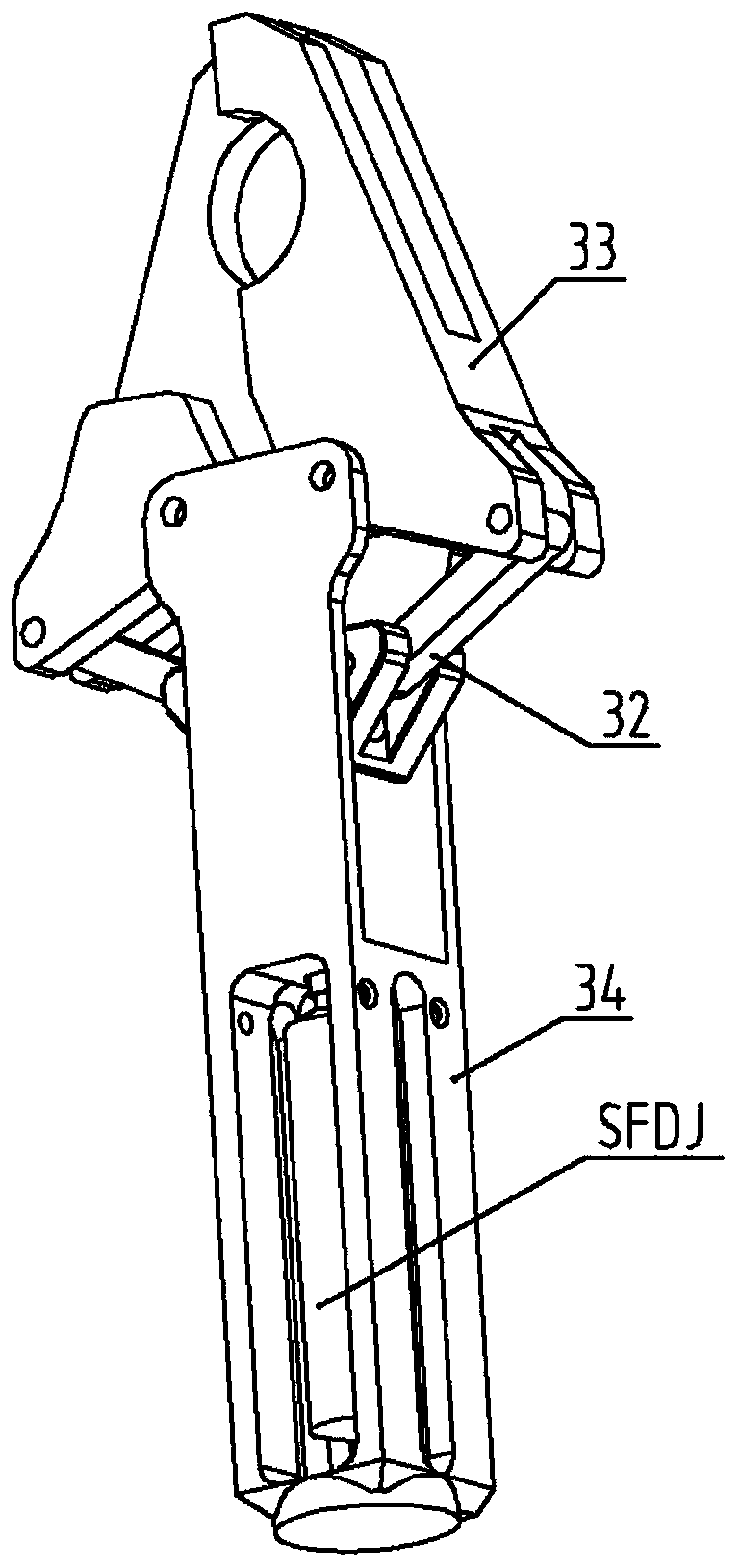

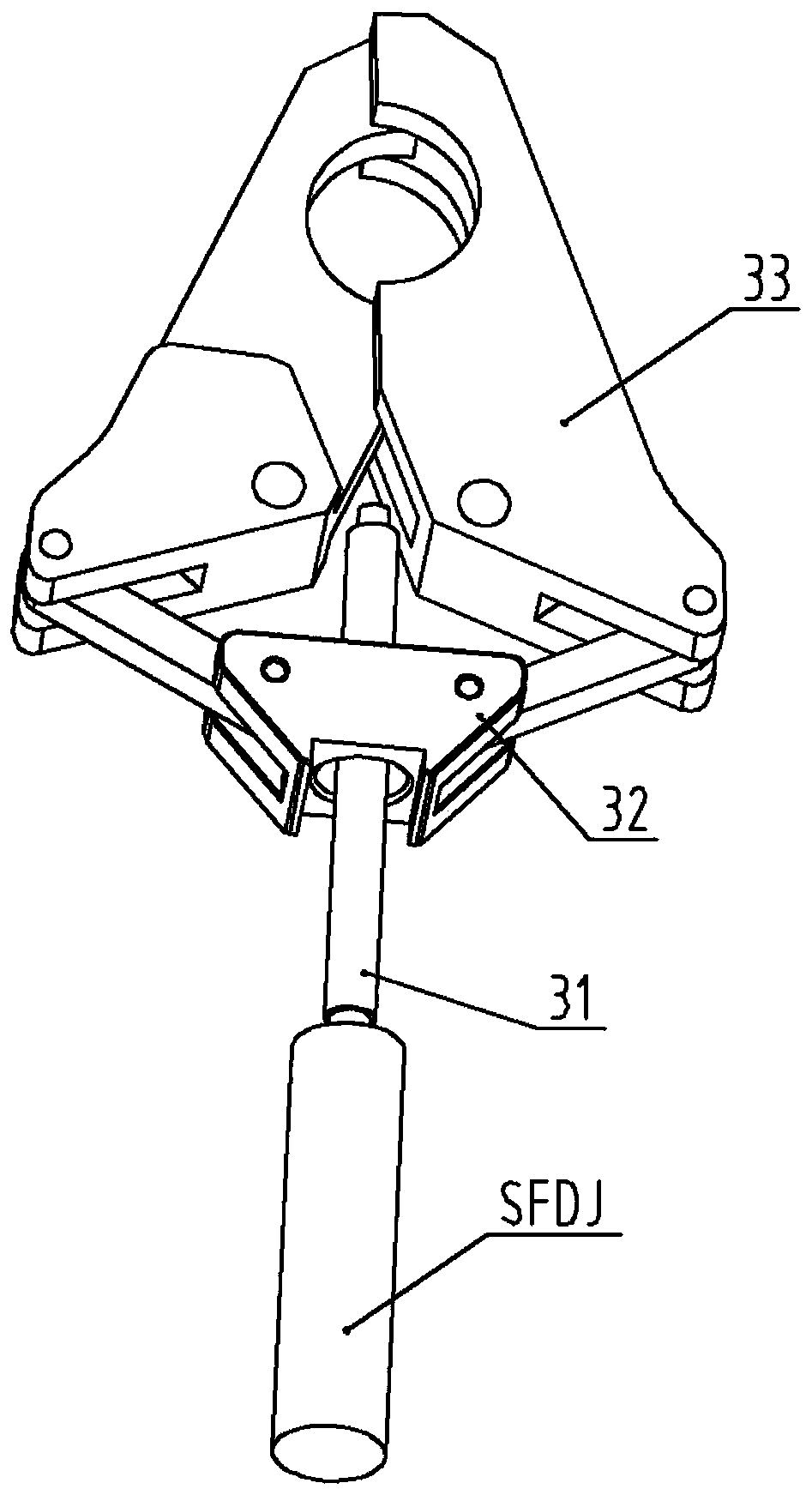

[0038] The working robot platform 2 includes a control box 21 and a first mechanical arm 22 and a second mechanical arm 23 installed on both sides thereof. The end of the first mechanical arm 22 is connected to the clamping tool 3, and the end of the second me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com