LCI valve group device

A valve group and component technology, applied in the direction of starting devices, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of poor ventilation and heat dissipation, large space occupation, high cost, etc., to achieve convenient installation and debugging, and low production cost The effect of low cost and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

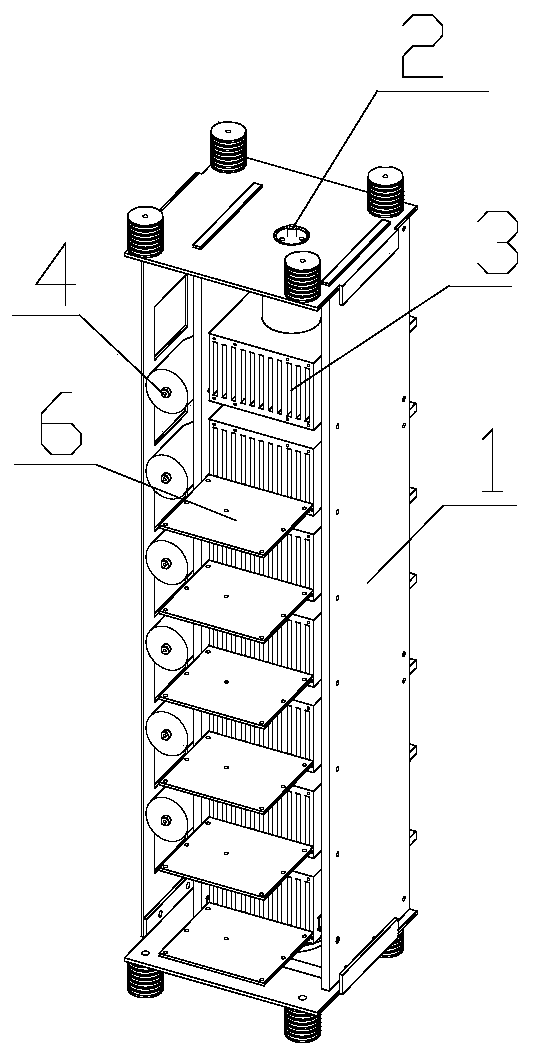

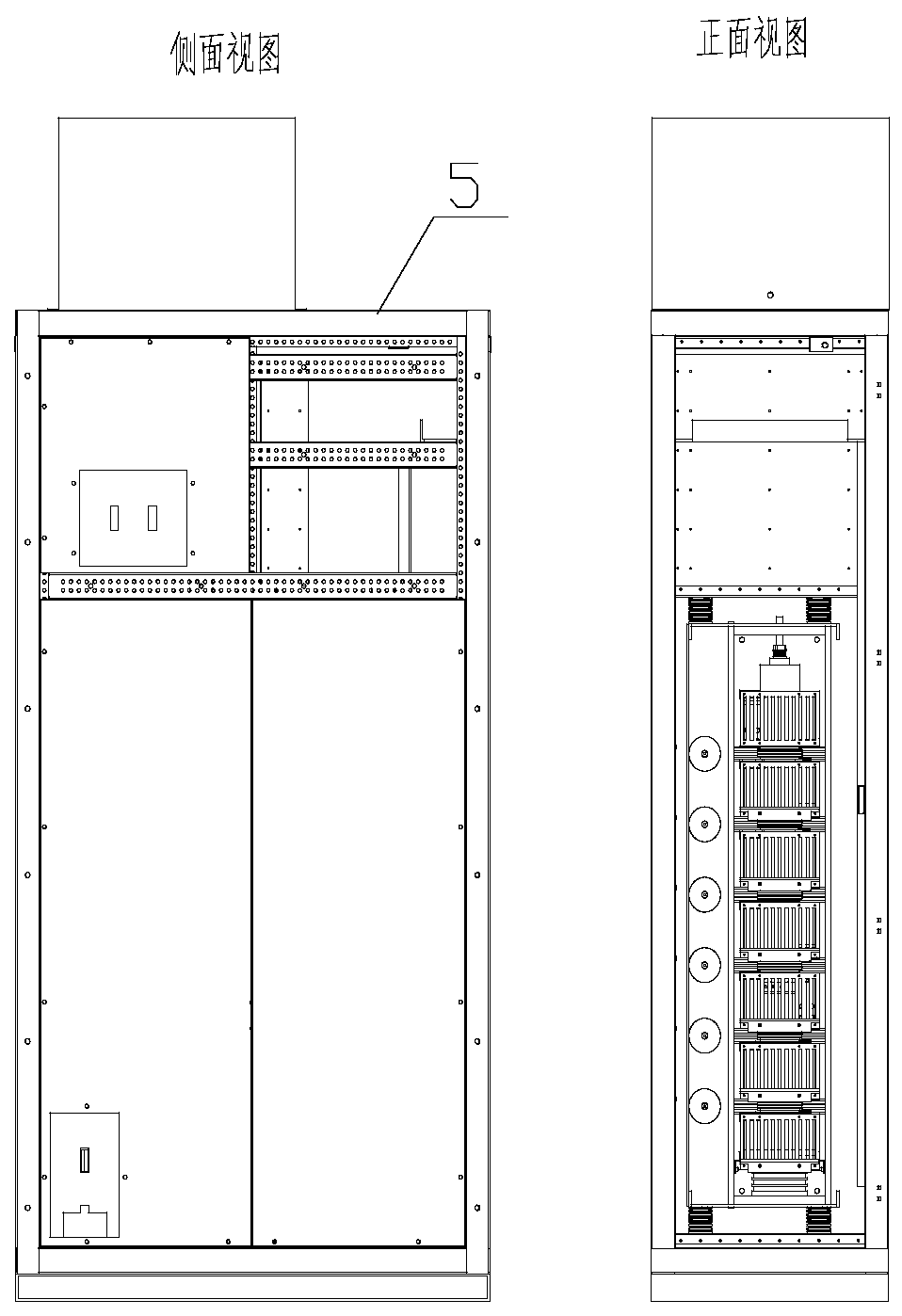

[0013] Such as figure 1 with figure 2 As shown, an LCI valve group device involved in this embodiment includes an insulating housing 1, a disc spring device 2, a heat sink group 3, a capacitor 4, a metal cabinet assembly 5, and a trigger plate 6; the insulating housing 1 The device casing is processed and combined with insulating materials, including the top plate, bottom plate, back plate and two side plates, which effectively play the role of insulation protection and can reduce weight in terms of material properties;

[0014] The heat sink group 3 is vertically arranged inside the insulating housing 1, and is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com