Locking and unlocking mechanism assembly for charging

A technology of adding an unlocking and locking mechanism, applied in the field of quick battery replacement, which can solve the problems of high price of small motors, large horizontal and vertical dimensions, limited output torque, etc., to meet the load requirements of quick battery replacement and facilitate promotion Application, the effect of reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

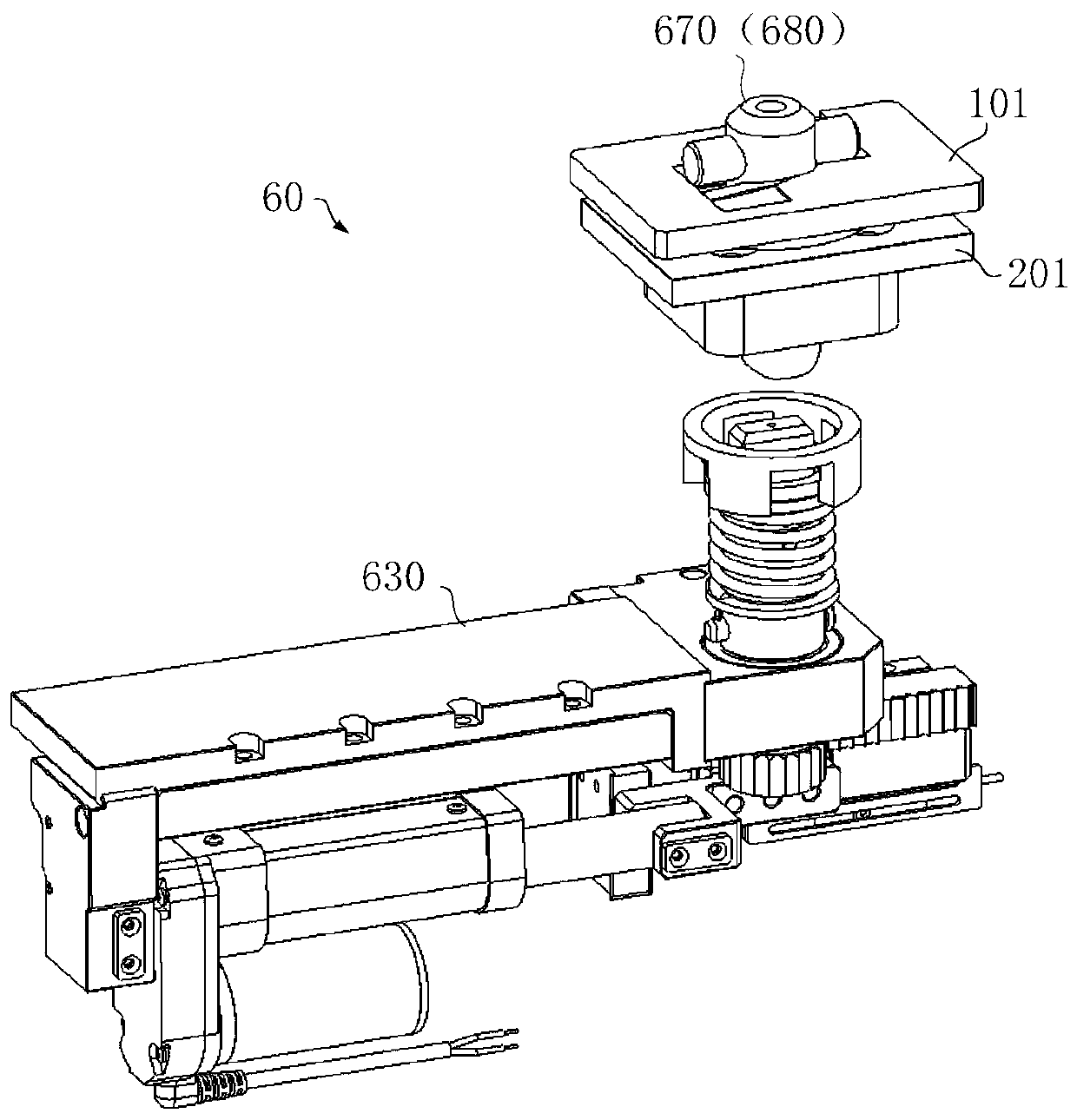

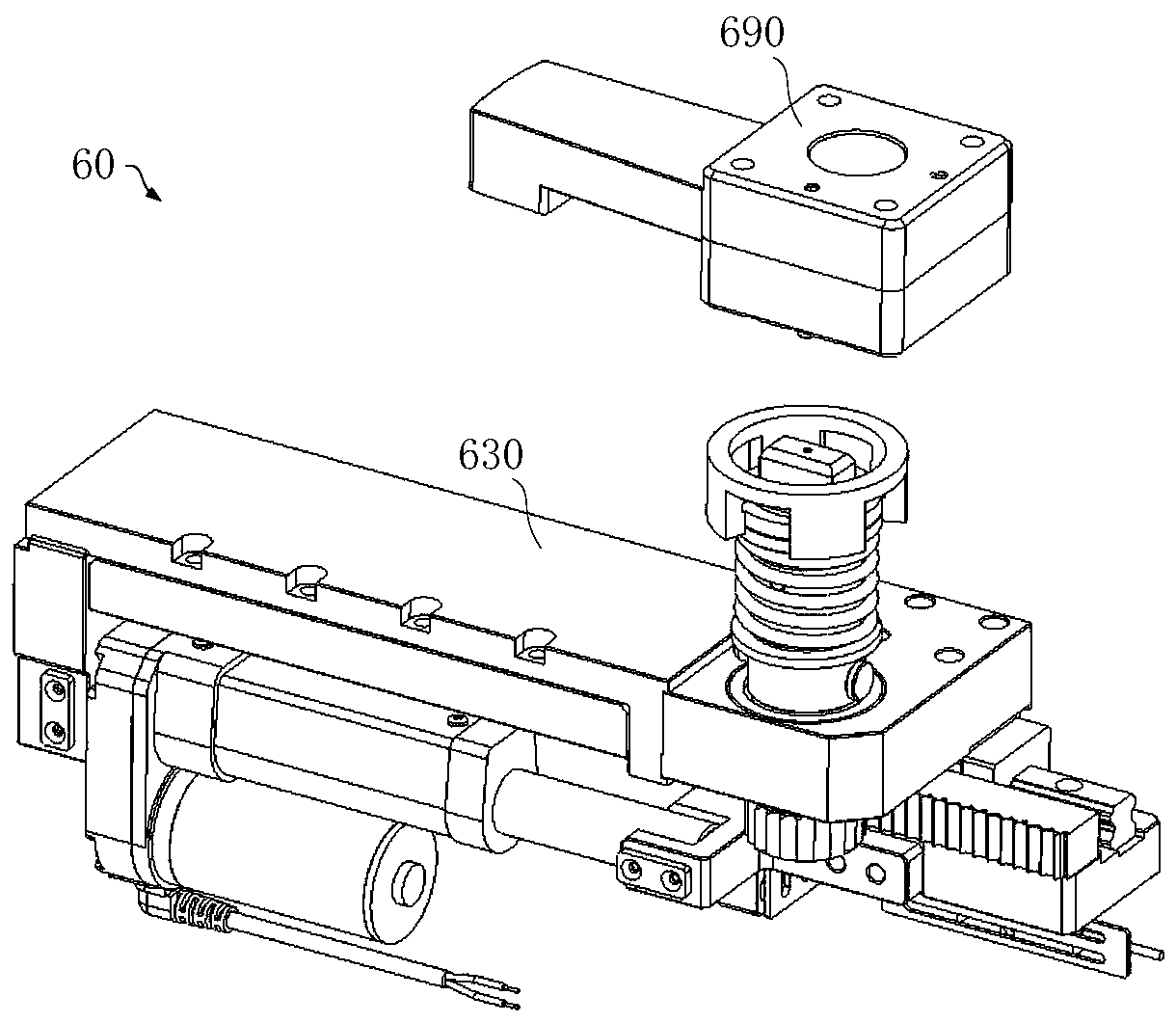

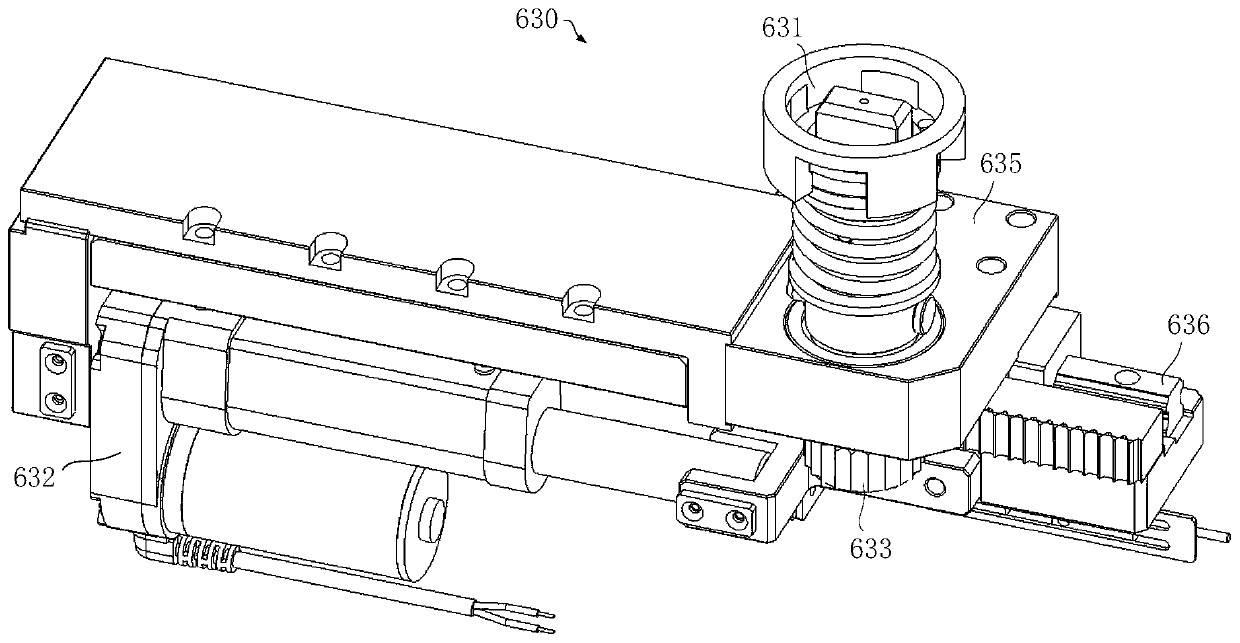

[0083] Embodiment 1. Rotate and unlock the main body 630:

[0084] Such as Figure 3-9 As shown, the rotary unlocking body 630 includes an unlocking assembly 631, a linear drive assembly 632, and a transmission structure; among them,

[0085] The unlocking assembly 631 includes an unlocking ring 6311, an unlocking rotary block 6314; the unlocking ring 6311 abuts the locking mechanism of the battery assembly and provides thrust for unlocking the locking mechanism of the battery assembly; the unlocking rotary block 6314 is used to provide a driving locking mechanism The torque of rotation; the unlocking ring 6311 is a hollow structure, and the unlocking ring 6311 is set outside the unlocking rotary block 6314;

[0086] The transmission structure is used to connect the linear drive assembly 632 and the unlocking and unlocking assembly 631. The transmission structure converts the linear motion into a rotary motion, so that the linear drive assembly 632 drives the unlocking rotary block 6...

Embodiment 2

[0093] Embodiment 2. The first locking mechanism body 670:

[0094] The locking mechanism is the first locking mechanism body 670, such as figure 1 As shown, the first locking mechanism body 670 is mounted on the battery substrate 201 of the battery assembly, while the first locking shaft 671 passes through the vehicle bottom substrate 101, and the first locking shaft 671 rotates to realize the battery assembly and the vehicle The quick lock and unlock.

[0095] Such as Figure 10-19 As shown, the first locking mechanism body 670 includes a first locking rotating shaft 671, a first locking pin 672, a first limiting housing, and a limiting member 675; wherein,

[0096] The first locking pin 672 is fixed through one end of the first locking rotating shaft 671, and the other end of the first locking rotating shaft 671 is used to contact the unlocking rotating block 6314;

[0097] The limiting member 675 is partially or fully placed in the limiting housing, and the first locking shaft 671...

Embodiment 3

[0110] Embodiment 3. The second locking mechanism body 680:

[0111] The locking mechanism is the second locking mechanism body 680, such as figure 1 As shown, the second locking mechanism body 680 is mounted on the battery substrate 201 of the battery assembly, and the first locking shaft 671 passes through the vehicle bottom substrate 101 of the vehicle, and rotates through the second locking shaft 681 to realize the battery assembly and the vehicle The quick lock and unlock.

[0112] Such as Figure 20-30 As shown, the second locking mechanism body 680 includes a second locking shaft 681, a second locking pin 682, a second limiting housing, a limiting block 685, an elastic member 687, and a thrust ring 688;

[0113] The second locking pin 682 is fixed through one end of the second locking shaft 681, and the other end of the second locking shaft 681 is used to contact the rotating power assembly; the second locking pin 682 is used to rotate to lock or unlock the battery assembly;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com