Collecting and discharging device for LED module dispensing machine

A technology of LED modules and dispensing machines, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that affect the lighting of LEDs, the box body is easy to slide out of the platform, and the box body is irregular. Simple, good adaptability, accurate dispensing and connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

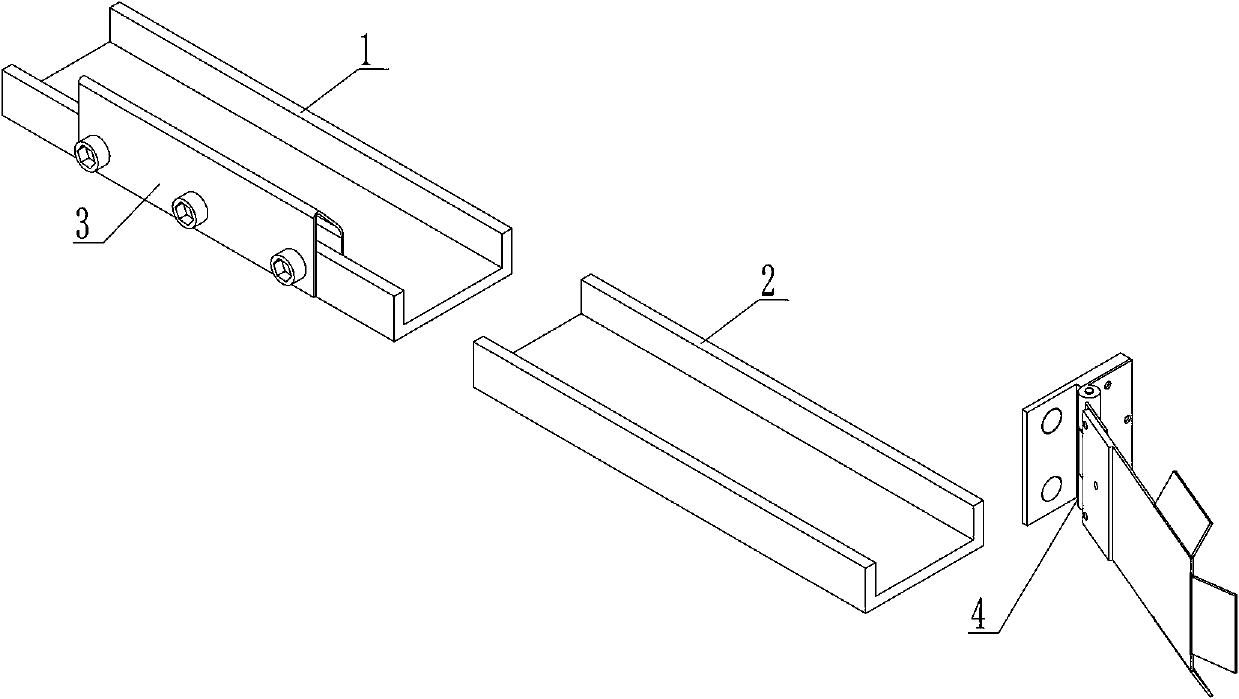

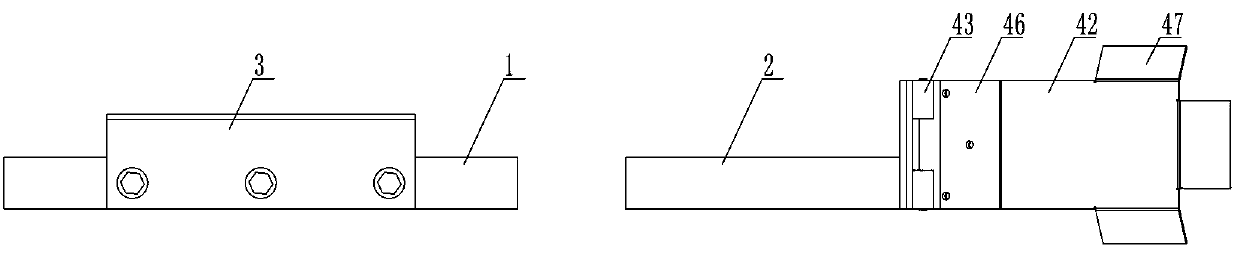

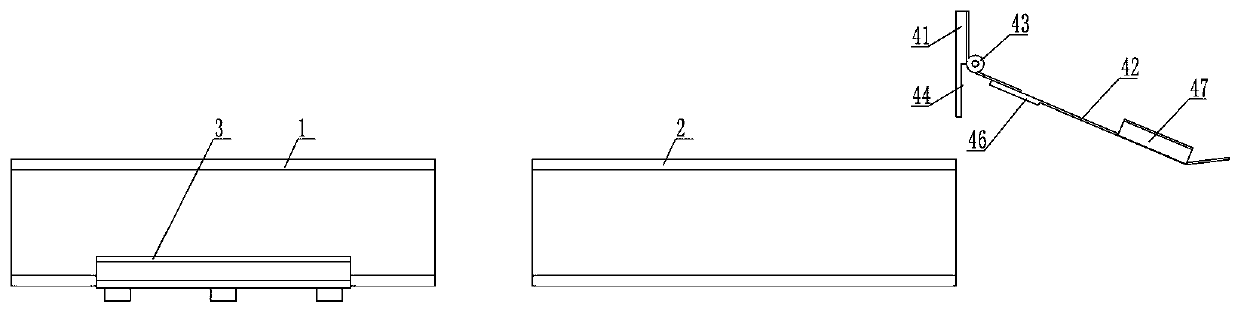

[0031] Such as Figure 1~Figure 6 Among them, an LED module dispensing machine receiving and unwinding device, which includes a feed table 1, a discharge table 2, a limit plate 3 and a stopper mechanism 4; the feed table 1 and the discharge table 2 are located at the same The axes correspond to each other; the limiting plate 3 is connected to the feeding table 1; the blocking mechanism 4 is located on one side of the discharging table 2; the baffle plate 42 of the blocking mechanism 4 can be flipped and folded; the The baffle plate 42 is turned over and reset and is connected and fixed with the fixing seat 41 to block the discharge port of the discharge platform 2 . The structure is simple, by setting the limit plate 3 on the feeding table 1, and setting the stop mechanism 4 on the side of the discharging table 2, the feeding table 1 and the discharging table 2 are located on the same axis, and the box body with the circuit board is located at the inlet The material is fed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com