All-terrain crane suspension arm and use method

A crane and all-terrain technology, which is applied in the direction of cranes, load hanging components, transportation and packaging, etc., can solve the problems of reduced hoisting capacity of the whole machine, insufficient height or range, and heavy weight, so as to achieve good weight and improve hoisting performance , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and embodiments.

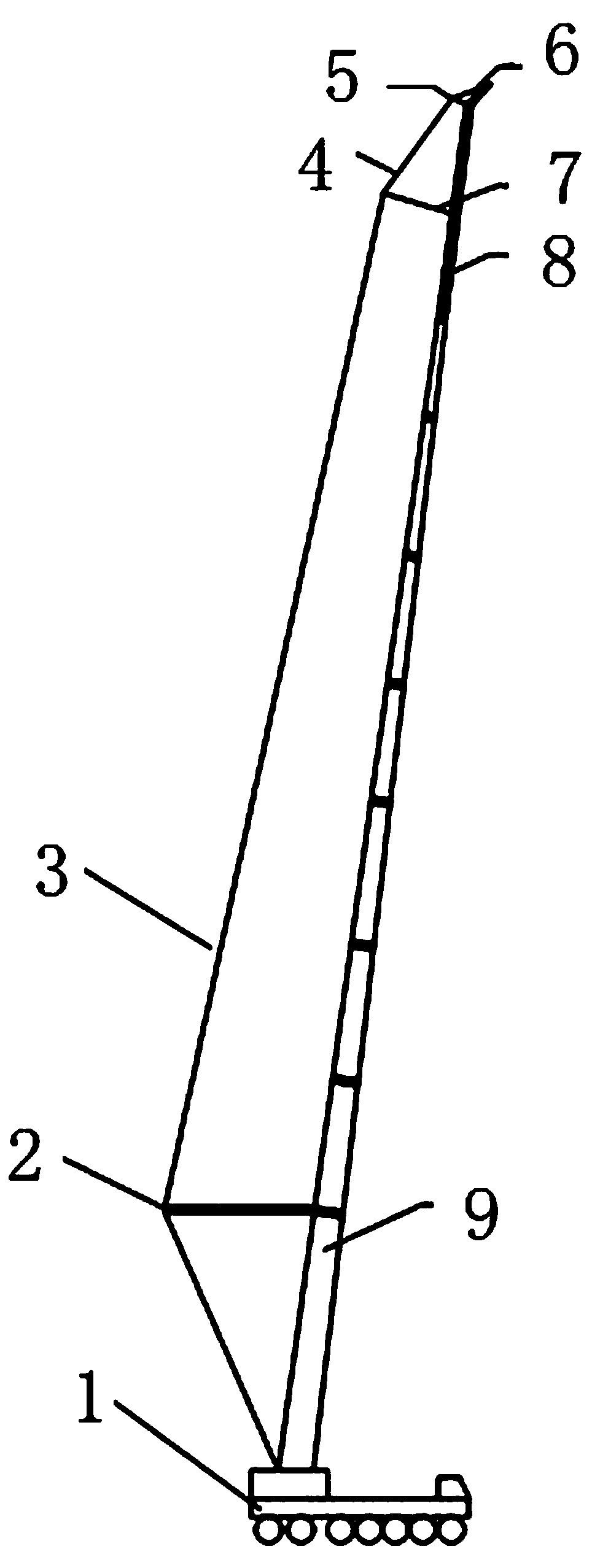

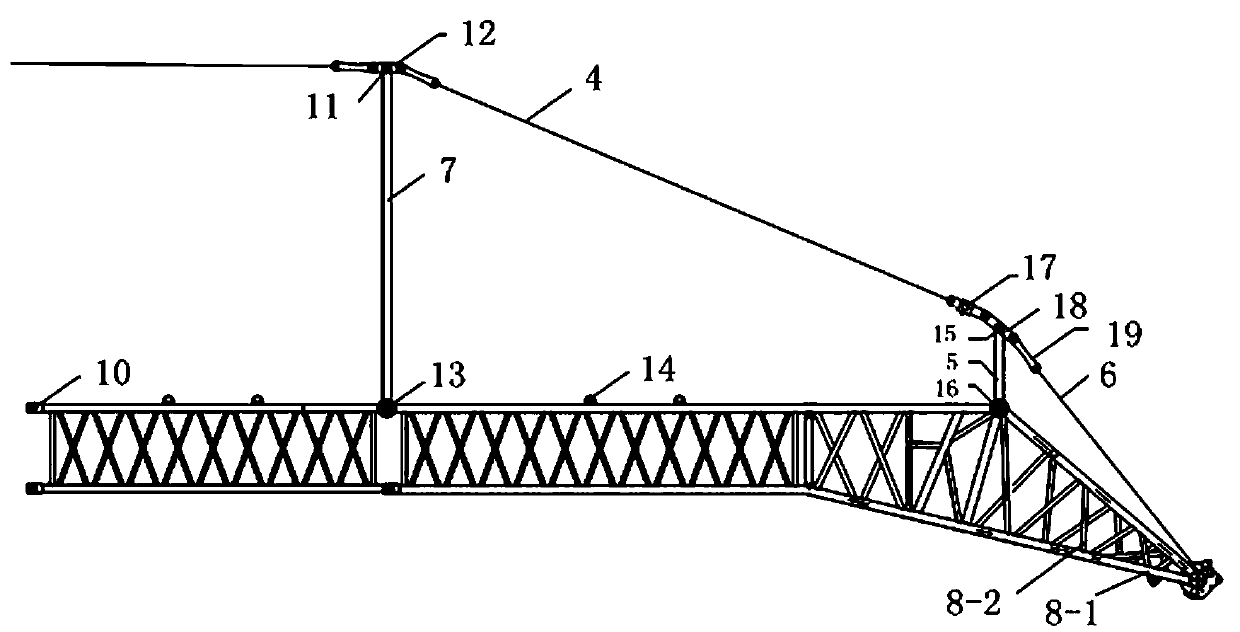

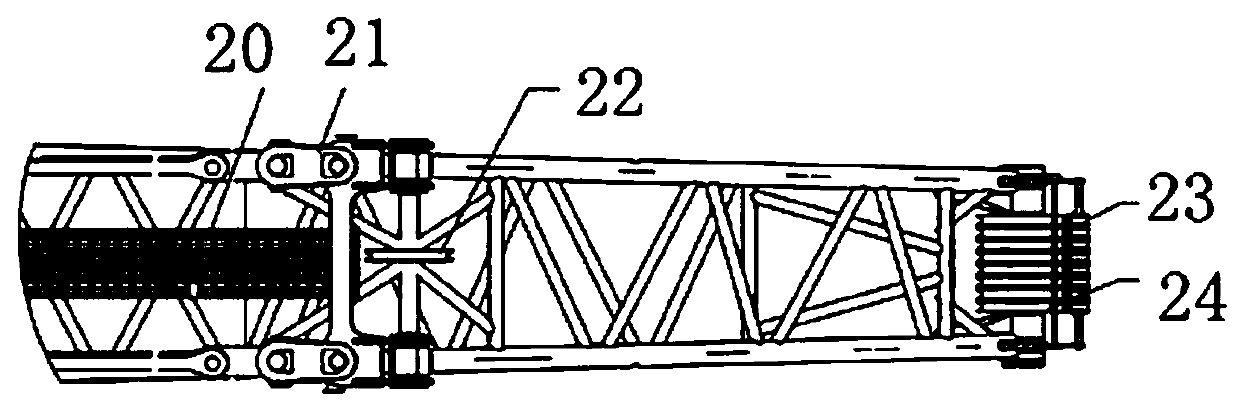

[0018] Such as figure 1 , Figure 2a and Figure 2b As shown, a boom of an all-terrain crane includes a chassis 1, a main boom 9 is installed on the chassis 1, and a jib 8 is installed on the jib head of the main jib 9, and the jib 8 is arranged by a jib main beam 8-1 and a cross arrangement A jib bracket 8-2 is formed between a plurality of jib main beams 8-1, the jib 8 is connected to the arm head of the main jib 9 through the main jib connection hole 10, and the jib 8 and the support rod 5 are hinged on the support Rod hinge point 16, the auxiliary arm 8 and the second support rod 7 are hinged at the second support rod hinge point 13, the support rod 5 is hinged at the corner of the auxiliary arm 8, and the main arm 9 is provided with a Y-shaped or door-shaped arm frame The super lifting 2, the two ends of the super lifting 2 are all provided with a supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com