A Thermoelectric Furnace Based on Liquid Fuel Combustion

A technology of thermoelectric power generation and liquid fuel, applied in the direction of burners, combustion types, combustion methods, etc., can solve problems such as blower failure, personal safety hazards, insufficient combustion, etc., to reduce temperature, reduce heat loss, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

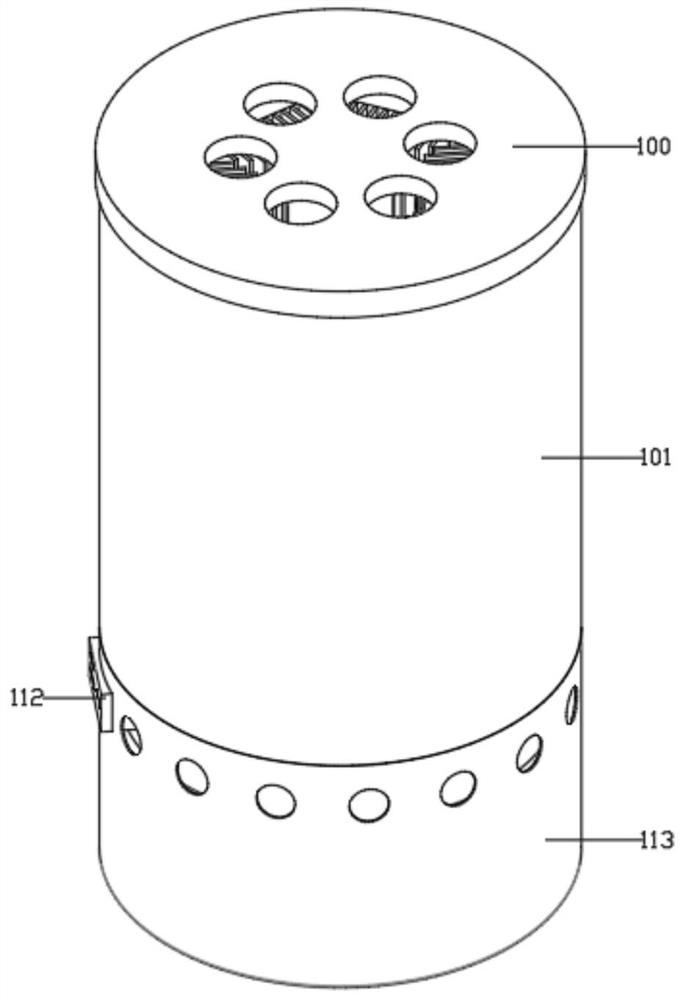

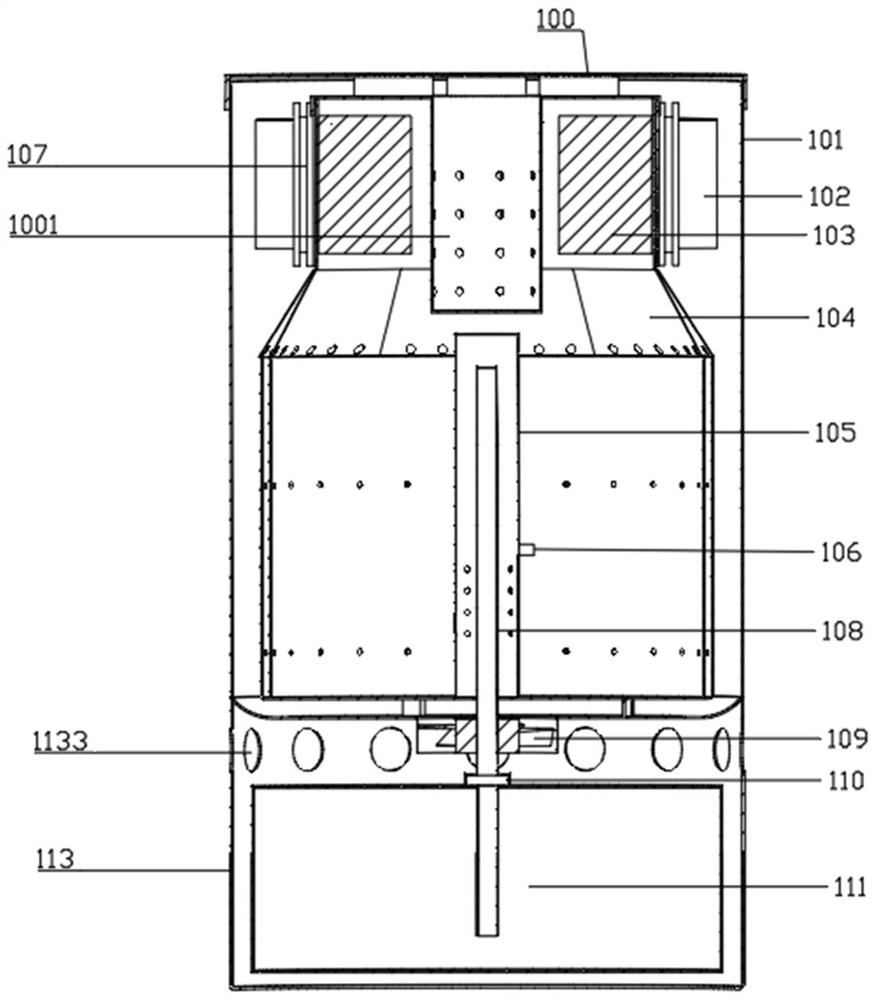

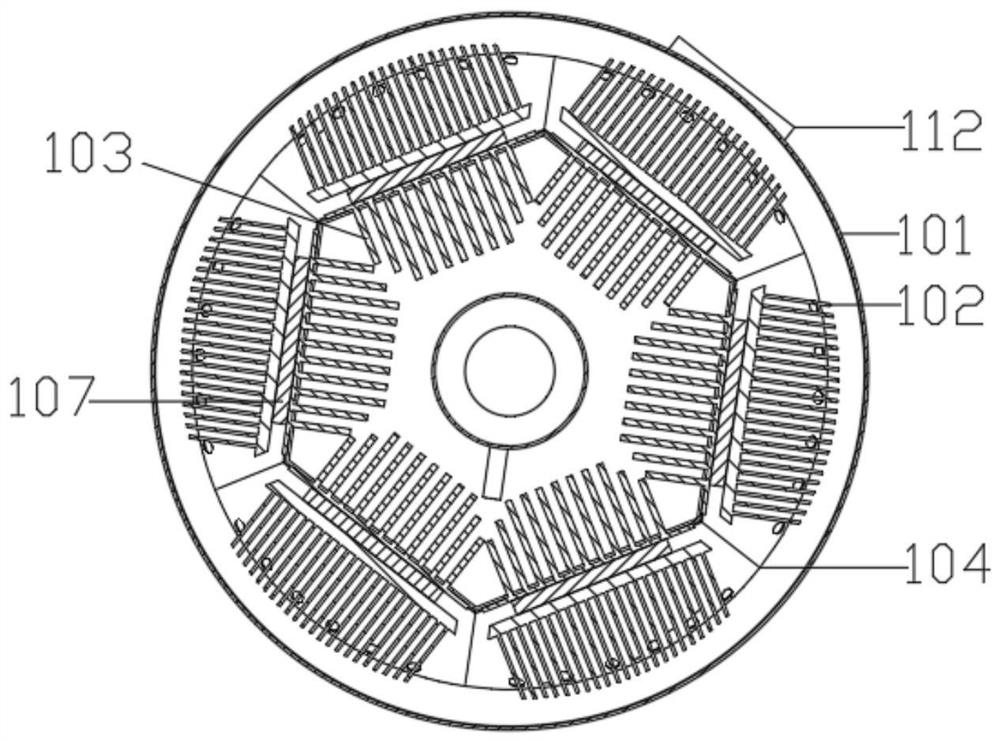

[0024] see figure 1 , figure 2 and image 3 , the present invention includes a furnace body, the furnace body includes an upper end cover 100, an outer cylinder 101, a radiator 102, a heat collector 103, an inner cylinder 104, an evaporation cylinder 105, an igniter 106, a thermoelectric sheet 107, an oil pipe 108, a fan 109, an oil pump 110, fuel tank 111, controller 112 and lower end cover 113. Wherein, an inner cylinder 104 is set inside the outer cylinder 101, and an upper end cover 100 is arranged on the top of the outer cylinder 101, see Figure 4 , the upper end cap 100 can seal the inner cylinder 104 and the outer cylinder 101 at the same time, and the upper end cap 100 and the inner cylinder 104 are sealed by an outer buckle, and the upper end cap 100 and the outer cylinder 101 are also sealed by an outer buckle.

[0025] Specifically, the upper end cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com