Real-time monitoring system and method for concrete vibration

A real-time monitoring and concrete technology, which is applied in the direction of measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of affecting signal sending and receiving, not being accurate enough, and unable to cover the whole area of vibration monitoring, etc., to achieve flexible and limited networking small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

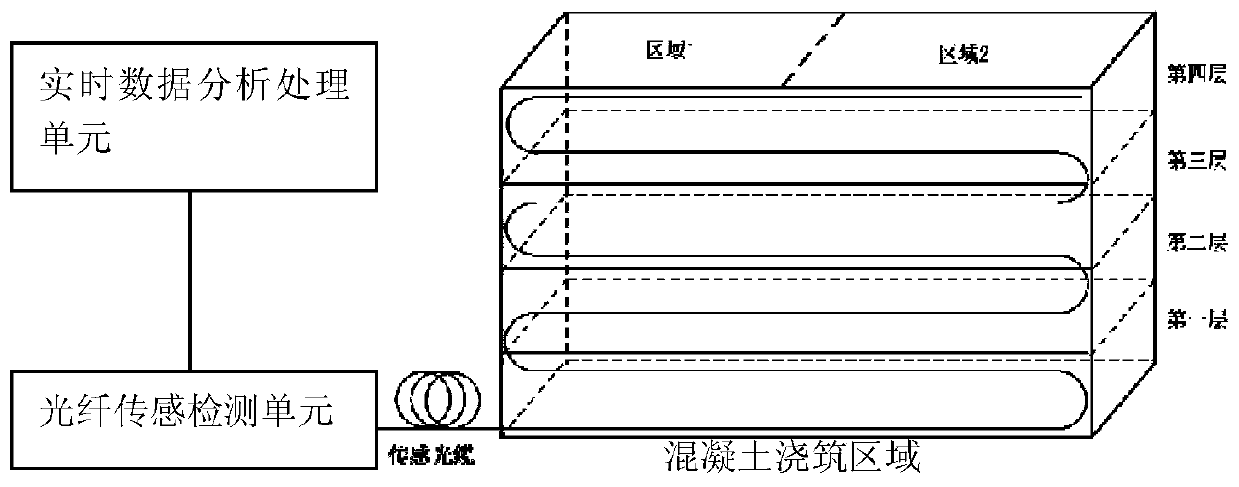

[0036] As shown in the figure, a real-time monitoring system for concrete vibration of the present invention includes a real-time data analysis and processing unit, an optical fiber sensing detection unit connected to the real-time data analysis and processing unit, and a sensing optical fiber connected to the optical fiber sensing detection unit .

[0037] The sensing optical fiber is arranged in the concrete pouring area, and is laid along the steel bar extension direction of the concrete steel bar frame. Such as figure 1 As shown, the sensing optical fiber in this embodiment is laid in a reciprocating manner, the concrete pouring area is divided into several pouring layers distributed up and down in units of layers, and the sensing optical fiber passes through all the pouring layers.

[0038] There are temperature sensing fibers and vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com