A detection device for the sealing performance of a rotary motion sealing ring that simulates a deep sea environment

A technology of rotary motion and sealing performance, applied in the field of marine engineering, can solve the problems of inability to complete the operation, less detection devices for sealing performance of the sealing ring, hidden safety hazards, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

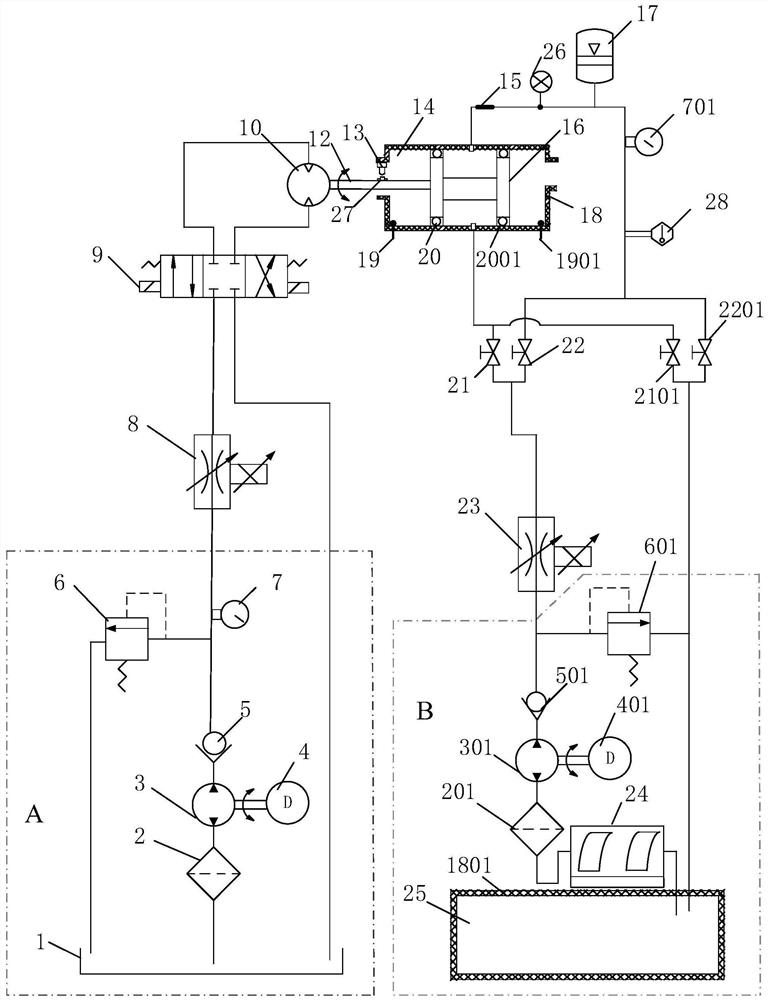

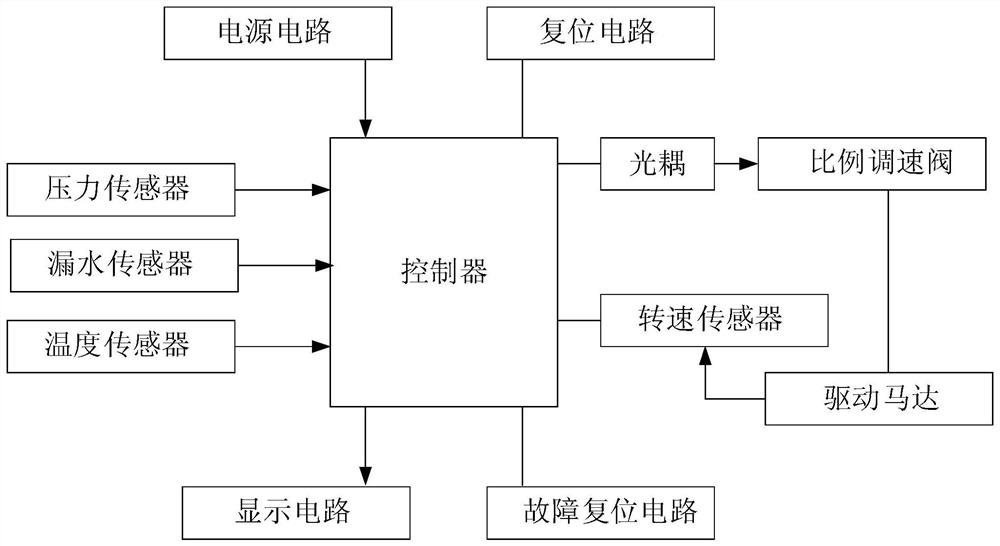

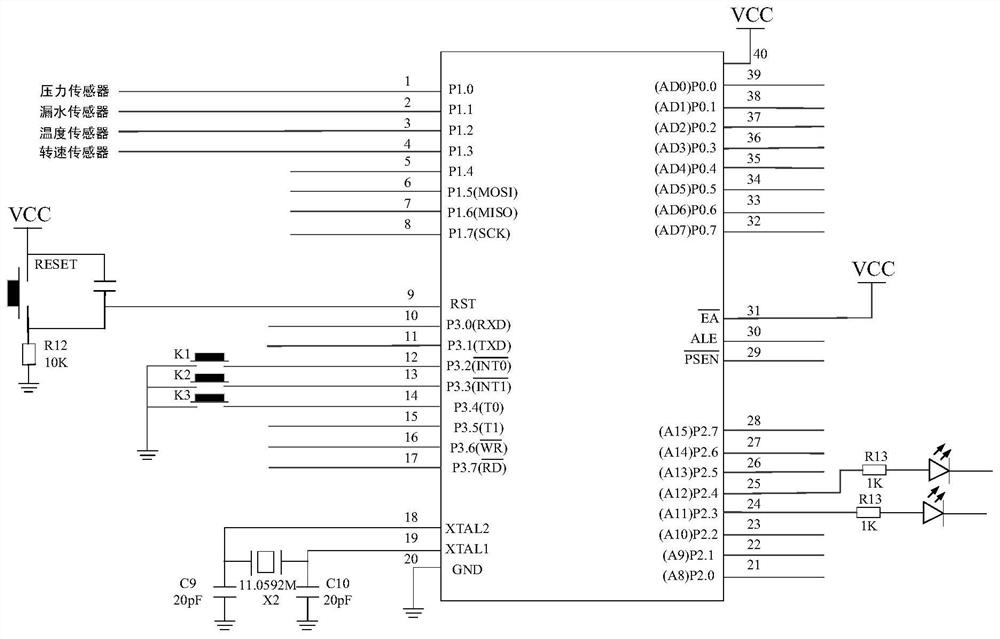

[0018] Such as figure 1 , 2 As shown, a detection device for simulating the sealing performance of the rotary motion sealing ring in deep sea environment, including hydraulic device A, hydraulic device B, high pressure cylinder 14, piston 16, sealing ring, speed sensor 13, pressure sensor 26, temperature sensor 15, water leakage Sensors, controllers, display circuits, reset circuits, and fault reset circuits; the outer layer of the high-pressure cylinder 14 is provided with an insulation layer I18, and the high-pressure cylinder 14 is provided with a piston 16, which is in the shape of an H. The cylinder 14 rotates, and the two ends of the piston 16 are symmetrically provided with a set of test sealing rings. The piston 16 forms a sealing structure with the inner cavity of the high-pressure cylinder 14 through the test sealing rings. The test sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com