Rotation dynamic sealing device

A rotary sealing and water sealing technology, applied in the components of pumping devices for elastic fluids, machines/engines, liquid fuel engines, etc. Simple and convenient installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

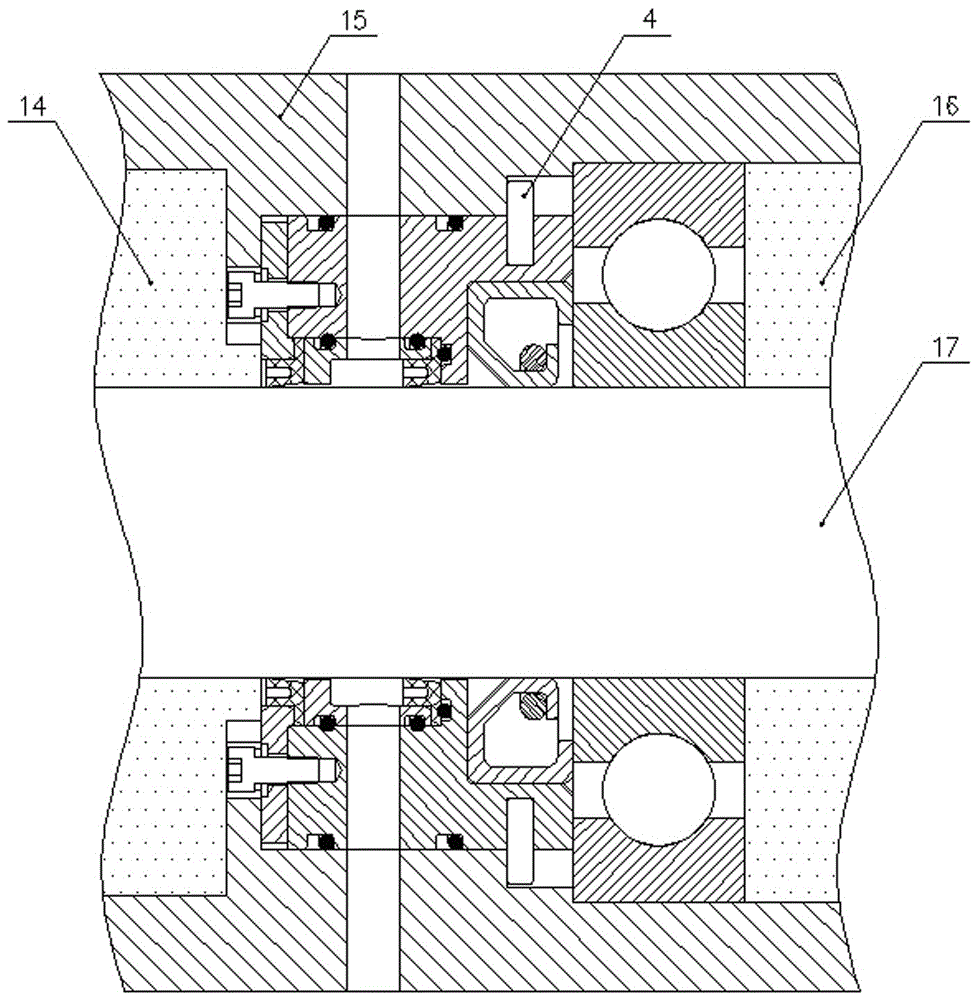

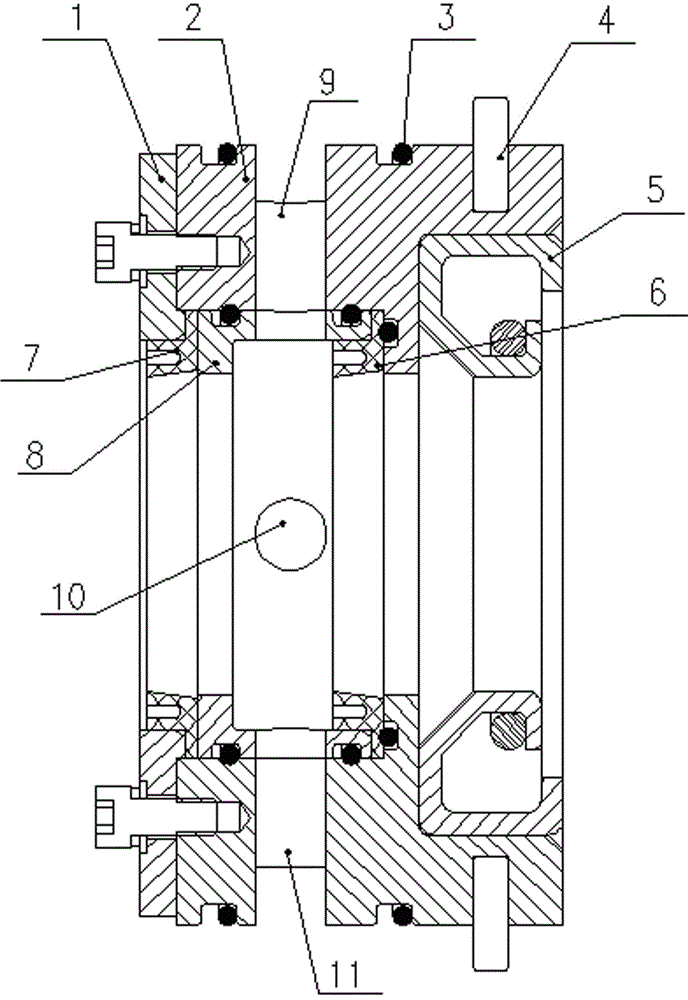

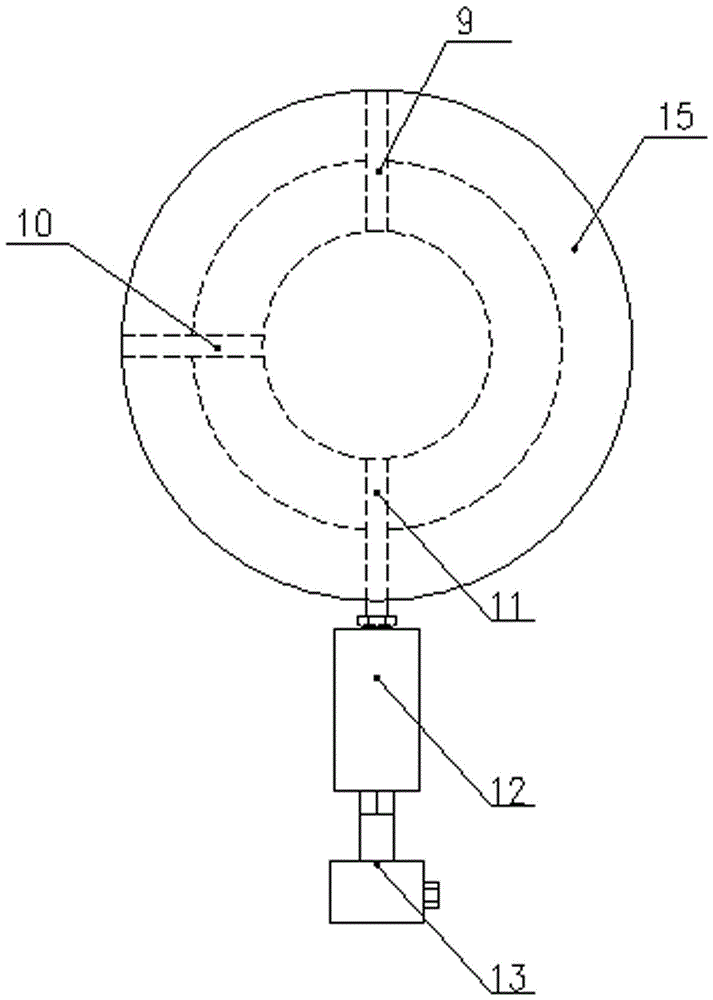

[0017] Referring to the drawings, it includes the first water seal 7, the second water seal 6, the oil seal 5, skeleton I1, skeleton II2, skeleton III8, O-shaped rubber ring 3 and cylindrical pin 4, skeleton I1, skeleton II2 and The assembly surface composed of skeleton III 8 is equipped with O-shaped rubber ring 3 to realize static sealing, and the first water seal 7, the second water seal 6, and the oil seal 5 are arranged in sequence from the water chamber side 14 to the bearing side 16 of the rotating shaft 17, The oil seal 5 is a skeleton oil seal, and the opening of the oil seal 5 faces the bearing side 16. After the skeleton I1, skeleton II2, and skeleton III8 are fixed as a whole, two seals are formed on the inner side which are in contact with the first water seal 7 and the second water seal 6. Matching sealing groove and fixed suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com