Heat treatment device and method for a high-performance iron-based superconducting wire

A heat treatment device, iron-based superconducting technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems such as difficult to obtain textured iron-based superconducting wires, and achieve It is conducive to large-scale popularization and application, reduces the complexity of the preparation process, and reduces the effect of heat treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific process of heat treatment is as follows:

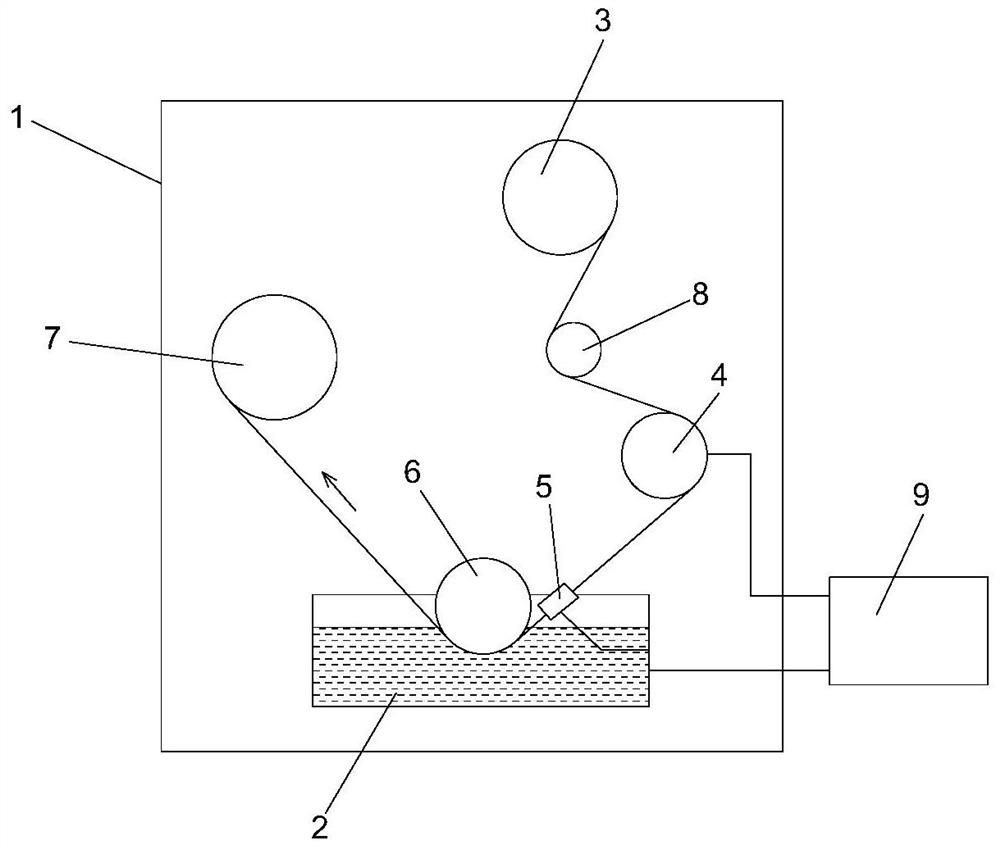

[0031] (1) Take an iron-based superconducting precursor wire with a length of 100 meters and a diameter of 1.5mm, process the head two meters into a diameter of 1.4mm, then put the wire into the pay-off reel 3, and use a drawing die with an aperture of 1.4mm 5, press figure 1 Threading is carried out as shown, through the liquid gallium pool 2, and finally the head of the wire is fixed on the take-up wheel 7.

[0032] (2) Close the door of the vacuum chamber 1, and evacuate; keep the vacuum degree in the vacuum chamber 1 at 10 -4 Pa;

[0033] (3) Turn on the heating module 9, use the constant current mode to heat, and adjust the heating current to make the maximum temperature of the wire reach 850 o C; Subsequently, turn on the driving motor of the take-up wheel 7, so that the moving speed of the wire is kept at 10mm / s; complete the heat treatment process of the wire.

[0034] (4) Replace the drawing die 5 wit...

Embodiment 2

[0039] The specific process of heat treatment is as follows:

[0040] (1) Take an iron-based superconducting precursor wire with a length of 200 meters and a diameter of 1.2mm, process the head two meters into a diameter of 1.14mm, then put the wire into the pay-off reel 3, and use a drawing die with an aperture of 1.14mm 5, press figure 1 Threading is carried out as shown, through the liquid gallium pool 2, and finally the head of the wire is fixed on the take-up wheel 7.

[0041] (2) Close the door of the vacuum chamber 1, and evacuate; keep the vacuum degree in the vacuum chamber 1 at 10 -4 Pa;

[0042] (3) Turn on the heating module 9, use the constant current mode to heat, and adjust the heating current to make the maximum temperature of the wire reach 900 o C; Subsequently, turn on the driving motor of the take-up wheel 7, so that the moving speed of the wire remains at 100mm / s; complete the heat treatment process of the wire.

[0043] (4) Replace the drawing die 5...

Embodiment 3

[0047] The specific process of heat treatment is as follows:

[0048] (1) Take an iron-based superconducting precursor wire with a length of 100 meters and a diameter of 1.5mm, process the head two meters into a diameter of 1.35mm, then put the wire into the pay-off reel 3, and use a drawing die with an aperture of 1.35mm 5, press figure 1 Threading is carried out as shown, through the liquid gallium pool 2, and finally the head of the wire is fixed on the take-up wheel 7.

[0049] (2) Close the door of the vacuum chamber 1, and evacuate; keep the vacuum degree in the vacuum chamber 1 at 10 -4 Pa;

[0050] (3) Turn on the heating module 9, use the constant current mode to heat, and adjust the heating current to make the maximum temperature of the wire reach 950 o C; Subsequently, turn on the driving motor of the take-up wheel 7, so that the moving speed of the wire is kept at 10mm / s; complete the heat treatment process of the wire.

[0051] (4) Replace the drawing die 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| superconducting critical temperature | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com