Method for determining the temperature of a solid electrolyte gas sensor

A solid electrolyte and sensor technology, used in instruments, scientific instruments, material analysis by electromagnetic means, etc., can solve problems such as increase in irreversible processes, permanent damage to sensor elements, and reduction in sensor electrode capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

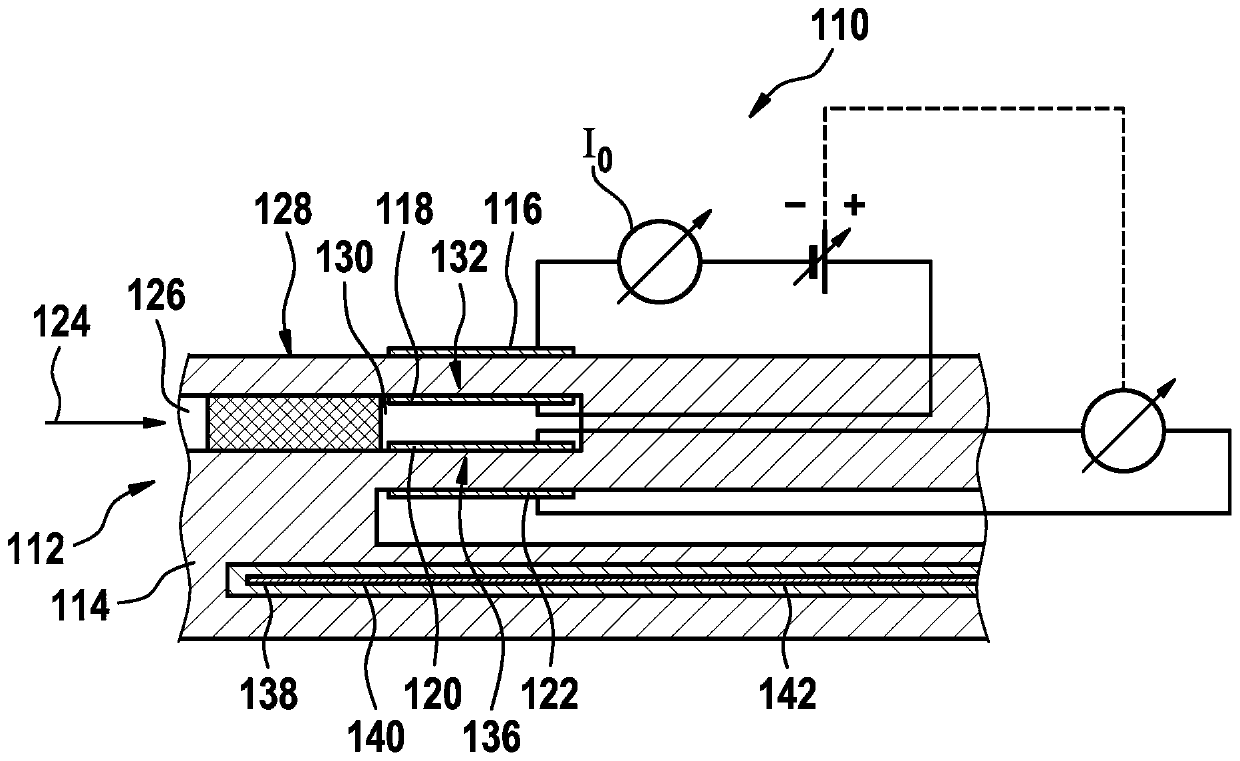

[0059] figure 1 The principle structure of the sensor 110 according to the invention is shown. figure 1 The sensor 110 shown in can be used to verify the physical and / or chemical properties of the measurement gas in the measurement gas space, wherein one or more properties can be detected. The invention is described below with reference in particular to the qualitative and / or quantitative detection of the gas composition of the measurement gas (in particular with reference to the detection of the oxygen fraction in the measurement gas). For example, the oxygen fraction can be detected as a partial pressure and / or as a percentage. In principle, however, other types of gas components such as nitrogen oxides, hydrocarbons and / or hydrogen can also be detected. Alternatively or additionally, however, other properties of the measurement gas can also be detected. The invention can be used in particular in the technical field of motor vehicles, so that the measurement of the gas sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com