Automatic steel casting device with track and use method of automatic steel casting device

A rail and steel pouring technology, applied in the configuration of indicating equipment/measuring equipment, casting molten material containers, manufacturing tools, etc., can solve the problems of easy failure, restricting the application of robots, and large limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

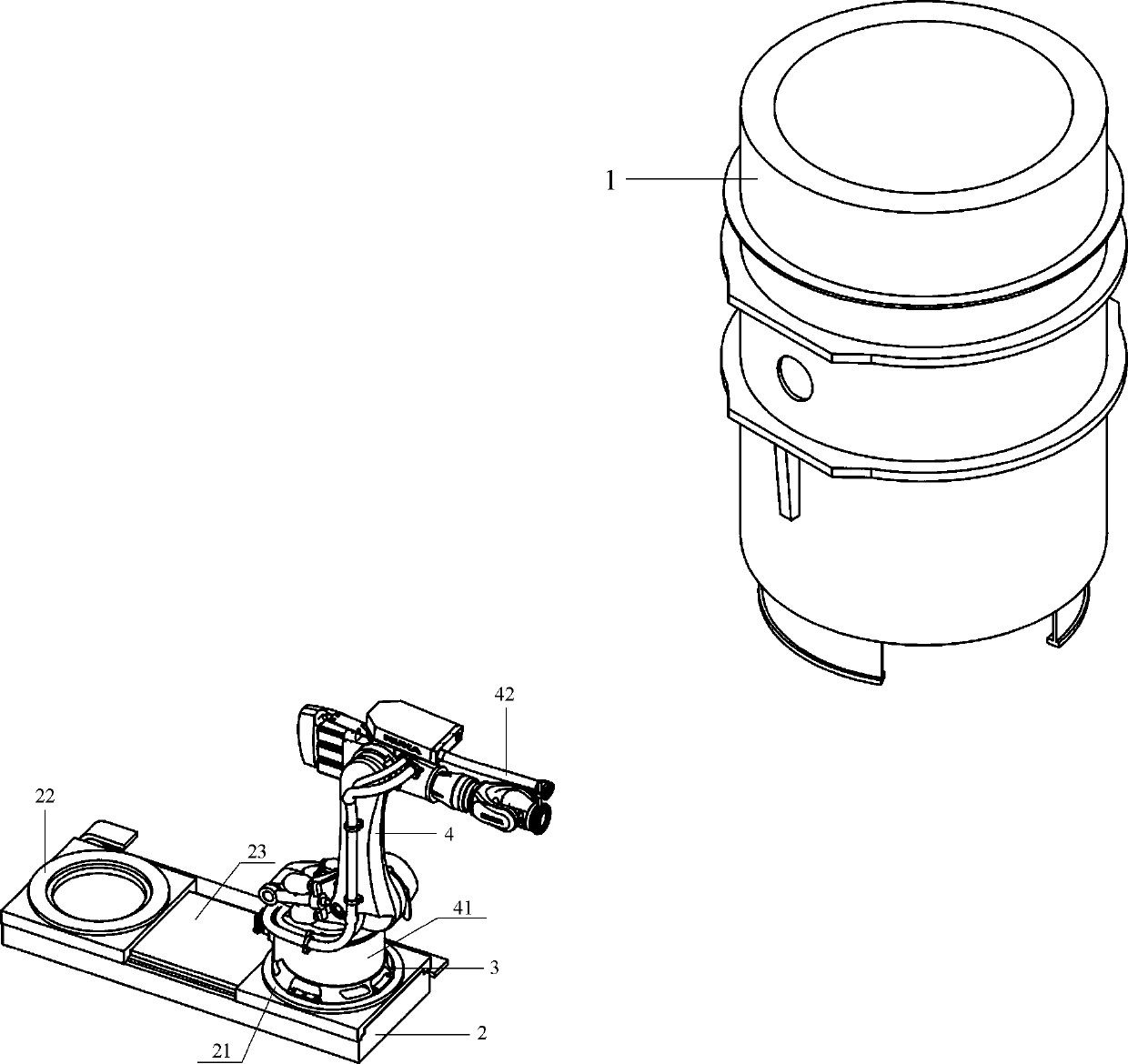

[0021] An automatic steel pouring device with a track, including a ladle 1, a platform 2, a mobile seat 3 and a robot 4, such as figure 1 As shown, the specific structure is:

[0022] The steel ladle 1 is set in the continuous casting area, the platform 2 is set on one side of the steel ladle 1, the platform 2 is provided with a working position 21 and a waiting position 22, the working position 21 is set on the end of the platform 2 closest to the steel ladle 1, and the waiting position 22 is set On the end of the platform 2 far away from the ladle 1, the working position 21 and the waiting position 22 are connected by a track 23;

[0023] The mobile seat 3 is movably arranged on the track 23;

[0024] The bottom and the top of the robot 4 are respectively provided with a base 41 and grippers 42 , the robot 4 is arranged on the moving base 3 through the base 41 , and the grippers 42 ensure that the robot 4 can complete related operations to the ladle 1 at the working positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com