Multifunctional rotating table device for ceramic machining

A ceramic processing and multi-functional technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of increased production costs, low efficiency, low degree of automation, etc., and achieve the effect of reducing production costs, high degree of automation, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

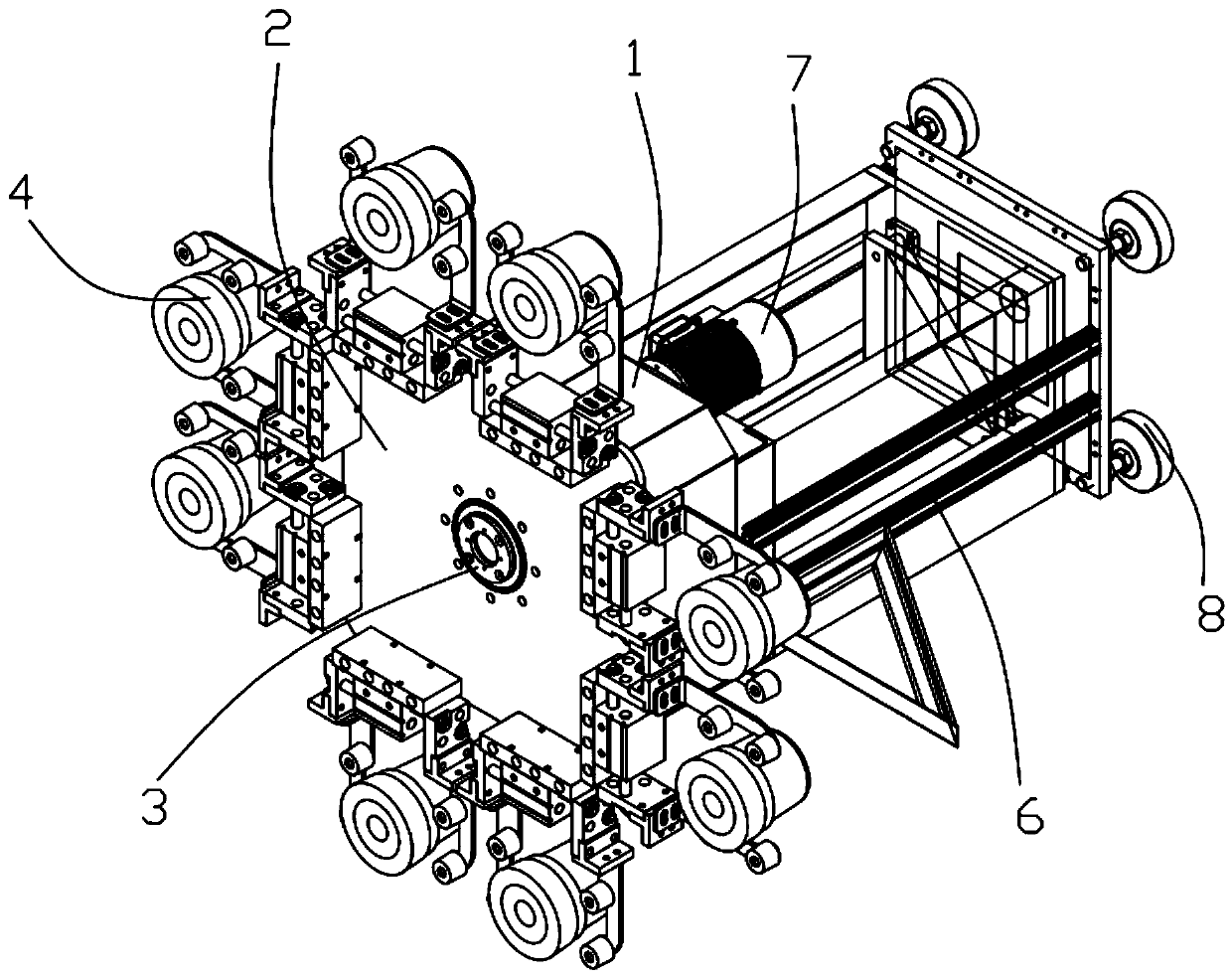

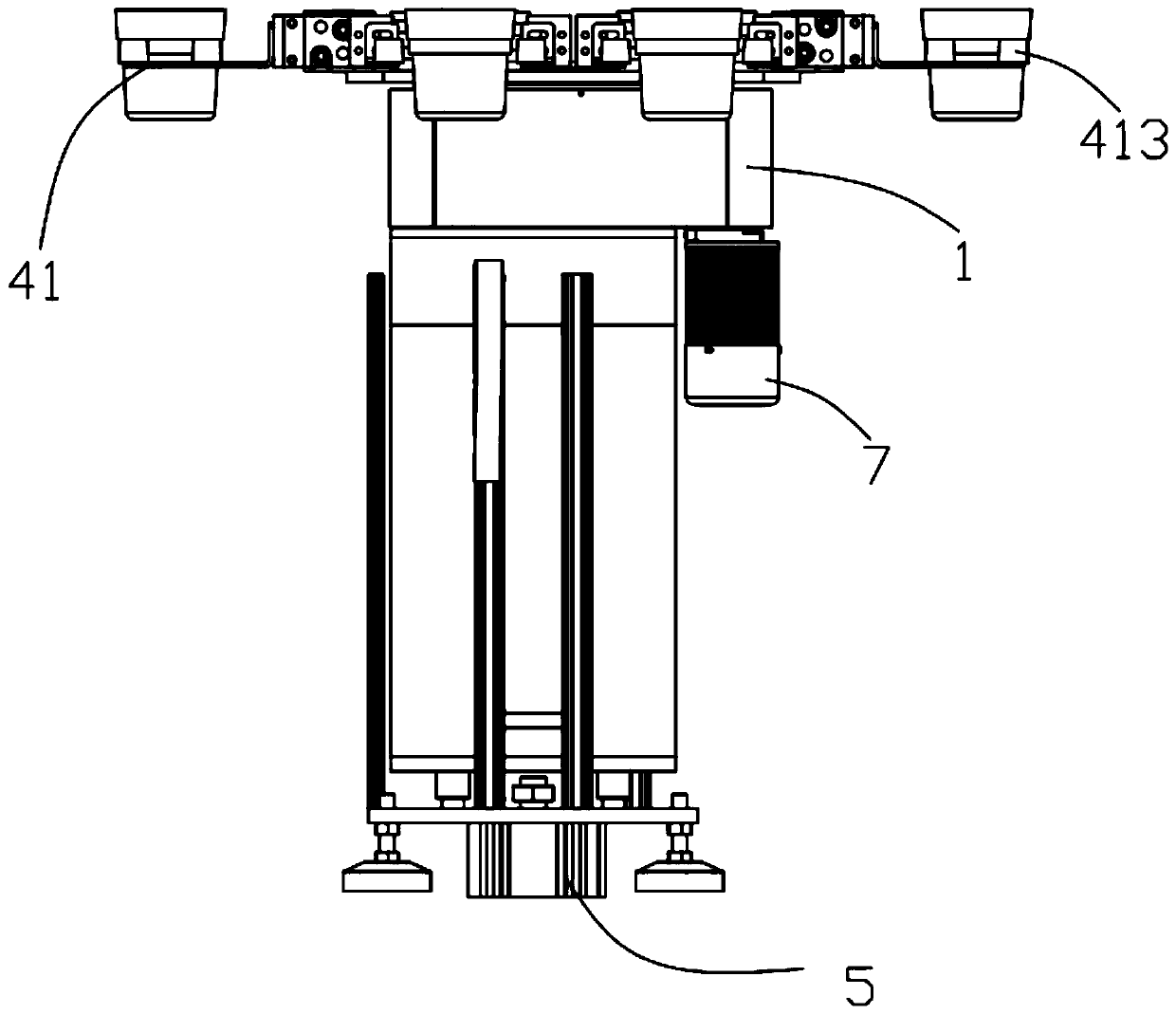

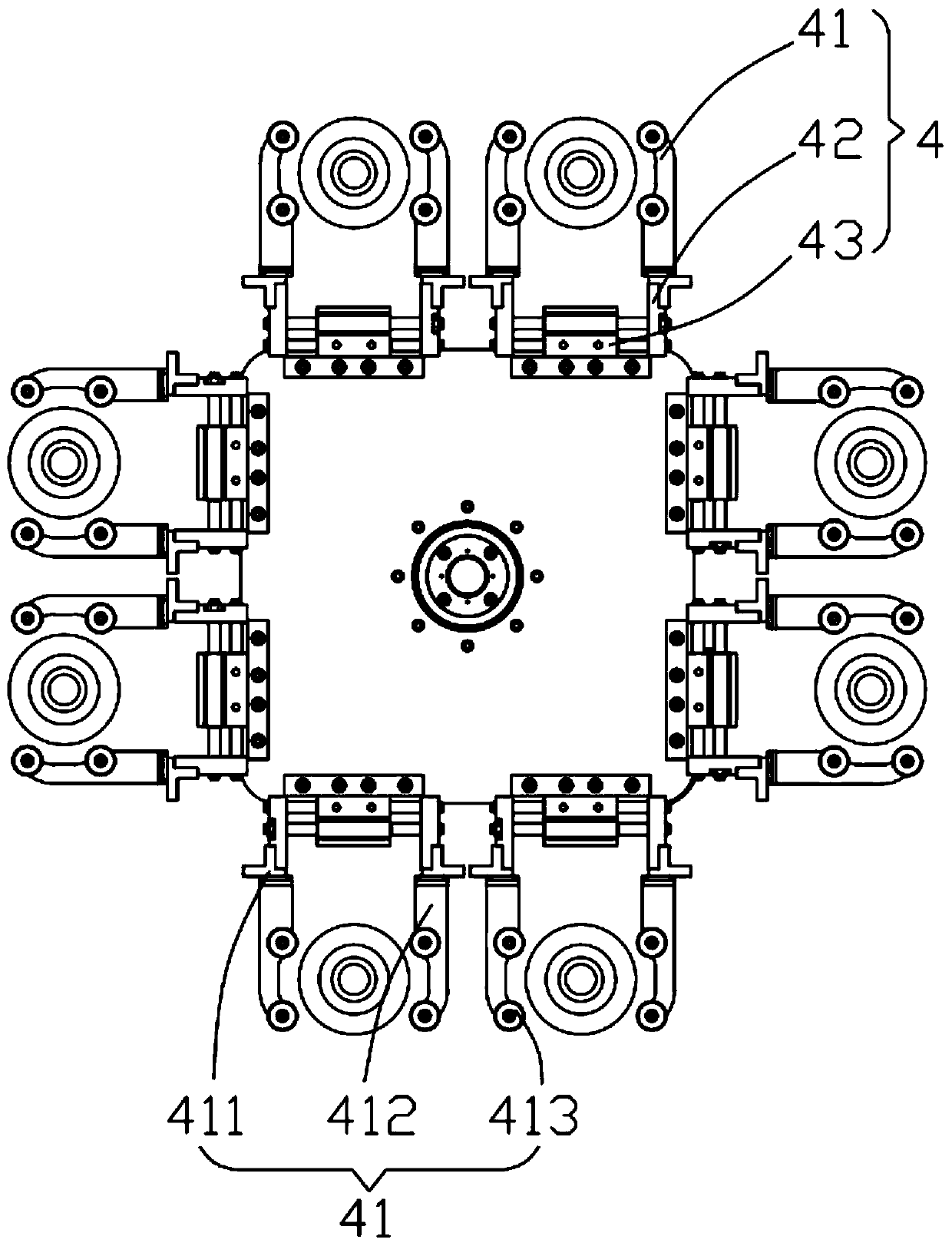

[0022] Refer to attached Figure 1-3 , this embodiment includes: a main body 1, a turntable 2 and a rotating shaft 3 disposed between the main body 1 and the turntable 2, the rotating shaft 3 and the turntable 2 are fixedly connected, and the rotating shaft 3 and the main body 1 are Rotation connection, eight turntable manipulators 4 are arranged in an array along the rotation axis 3 on the turntable 2, and the eight turntable manipulators 4 are divided into four groups, and the positions of the two groups of turntable manipulators 4 are respectively the same as those of the two roll forming machin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap