A paper structure cushioning protection device for environment-friendly packaging

A technology for protection device and packaging, applied in the field of paper structure buffer protection device, can solve the problems of affecting the end user's use cost, unfavorable overall transportation operation, and high proportion of cost framework, so as to improve the safety performance of packaging buffer, improve the sense of experience, The effect of enhancing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

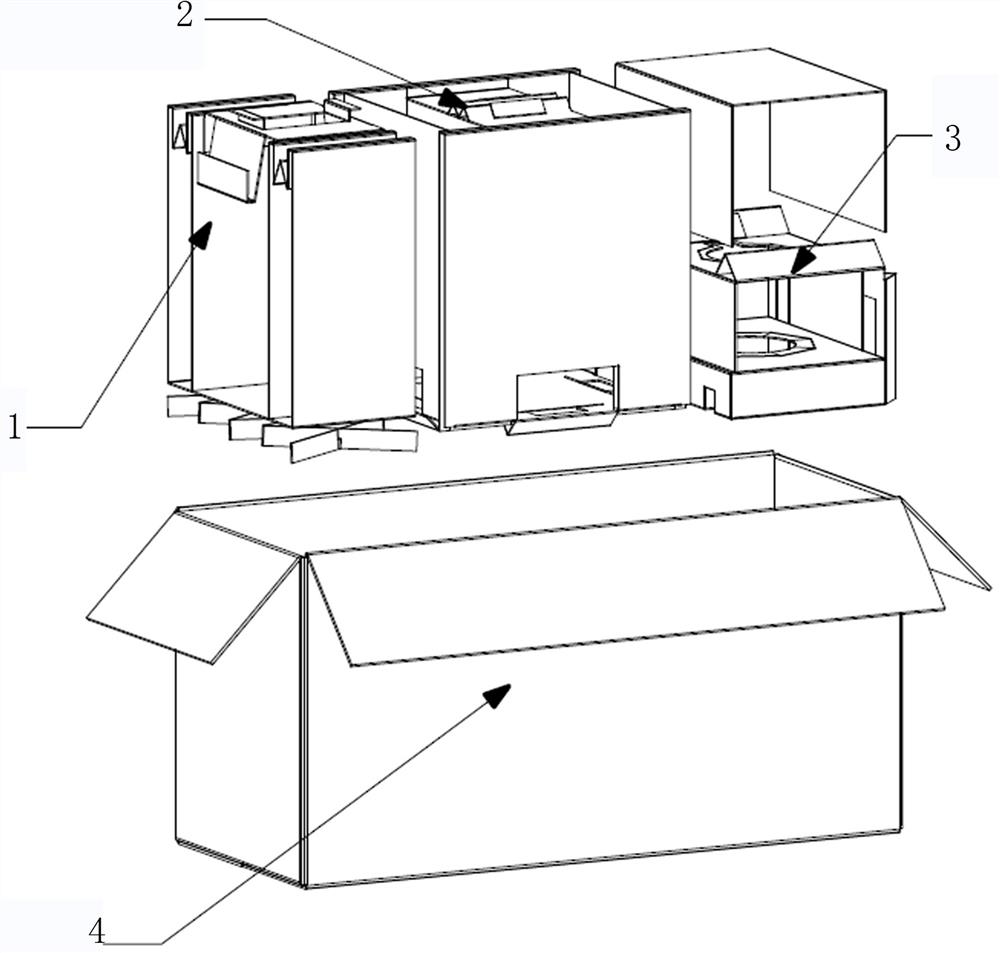

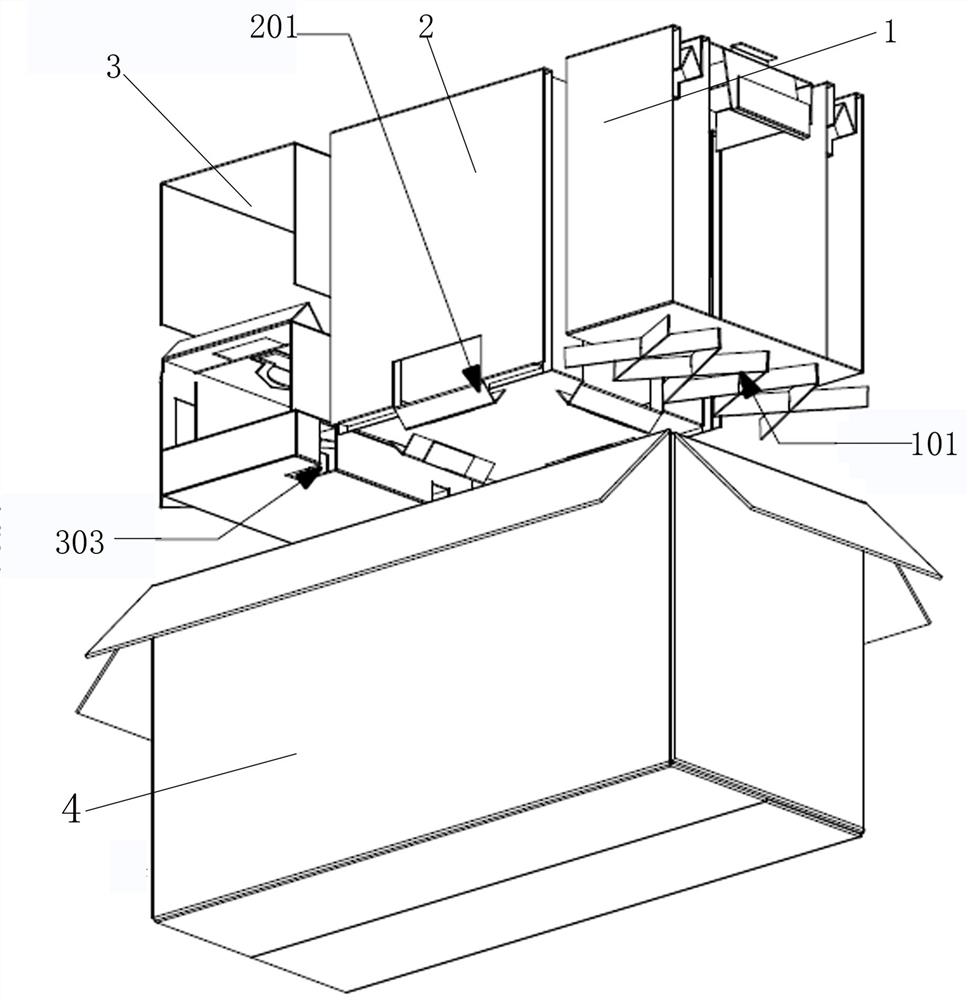

[0045] A paper structure buffer protection device for environment-friendly packaging, comprising a kitchen machine buffer part 1, a coffee machine stabilizing part 2, a coffee pot fixing part 3, and an outer box 4, the chef machine buffer part 1, coffee machine stabilizing part 2, The fixed parts 3 of the coffee pot are connected sequentially and parallel to each other, the buffer part 1 of the kitchen machine, the stable part 2 of the coffee machine, and the fixed part 3 of the coffee pot are connected and assembled and matched with the outer box 4;

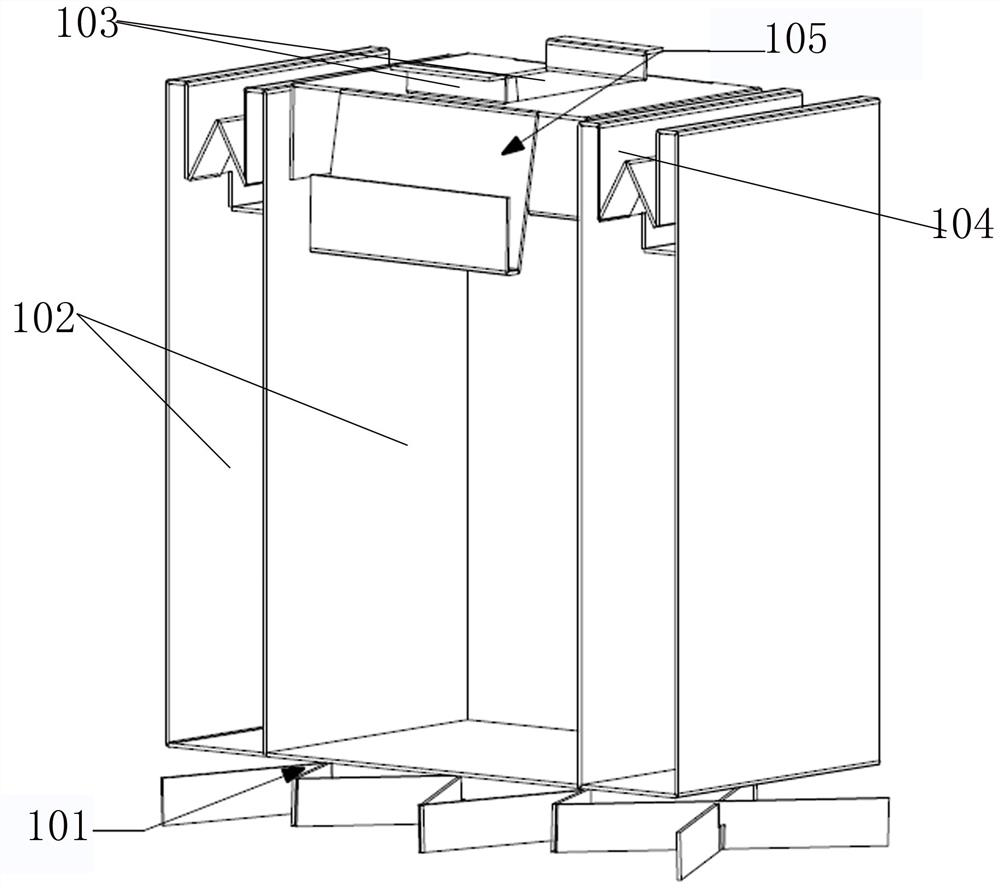

[0046] The bottom of the buffer part 1 of the kitchen machine is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com